Irradiated low-smoke halogen-free wire and cable

This product is suitable for transmission of electric energy in power lines with a rated voltage of 0.6/1KV and below. Irradiation cross-linking is the use of high-energy β-rays generated by irradiation to form polymer free radicals, and then polymer free radicals recombine into cross-linking bonds, thereby turning the original linear molecular structure into a three-dimensional network molecular structure. Cross-linked.

Classification:

Key words:

Irradiated low-smoke halogen-free wire and cable

- Description

- Model and specification

- Usage characteristics

- Parameter

- Transportation

-

- Commodity name: Irradiated low-smoke halogen-free wire and cable

- Commodity ID: 1329827700822134784

This product is suitable for transmission of electric energy in power lines with a rated voltage of 0.6/1KV and below. Irradiation cross-linking is the use of high-energy β-rays generated by irradiation to form polymer free radicals, and then polymer free radicals recombine into cross-linking bonds, thereby turning the original linear molecular structure into a three-dimensional network molecular structure. Cross-linked.

This product is suitable for power transmission in power lines with a rated voltage of 0.6/1KV and below.

Product Executive Standard: Enterprise Standard:Q/JS12.04-2011

Explanation of the principle of irradiation

Irradiation cross-linking is the use of high-energy & beta rays generated by irradiation to form polymer free radicals, and then polymer free radicals recombine into cross-linking bonds, thereby turning the original linear molecular structure into a three-dimensional network molecular structure. Form crosslinks.

Characteristics of radiation cross-linked low-smoke halogen-free wires and cables

Large current carrying capacity: irradiated cross-linked cables, after high-energy electron beam irradiation, the molecular structure of the material changes from linear to three-dimensional network molecular structure, and the temperature resistance level is increased from the non-crosslinked 70℃ to 90℃, 105℃, 125℃, 135℃, even 150℃, the current carrying capacity of cables of the same specification is increased by 15-50%.

Insulation resistance is large: because the radiation crosslinked cable avoids the use of hydride as a flame retardant, it prevents pre-crosslinking during crosslinking and the insulation layer absorbs air The phenomenon that the insulation resistance decreases due to the moisture. Thereby ensuring the insulation resistance value.

Long service life, strong overload capacity: due to the high temperature resistance grade and high aging temperature of the polyolefin material after radiation crosslinking, it prolongs the cycle of heating during use. Service life.

Environmental protection and safety: Since the materials used in the cables are all halogen-free and environmentally friendly materials, the combustion characteristics of the cables meet the requirements of environmental protection.

Product quality is stable: The quality of traditional warm water cross-linked cables is affected by water temperature, extrusion process, cross-linking additives and other factors, and the quality is unstable. The quality of radiation cross-linked cables depends on the radiation dose of the electron beam. The dose is controlled by a computer, without human factors, so the quality is stable.

Irradiation cross-linked low-smoke, halogen-free, flame-retardant wires and cables are difficult to catch fire and have the ability to prevent or delay the spread of flames. They have strong overload capacity. Moreover, once they catch fire, they have the characteristics of halogen-free, low-smoke, non-toxic, and non-corrosive. It is suitable for high-rise buildings, hotels, hospitals, subways, nuclear power plants, tunnels, power plants, mines, petroleum, chemical industries, etc.

Irradiation cross-linked low-smoke halogen-free fire-resistant wire and cable not only meets the characteristics of irradiated low-smoke halogen-free flame-retardant cable, it can also meet the power supply capacity of the line under fire conditions, and has a strong overload capacity. Mainly used in fire alarm, fire fighting equipment, smoke exhaust equipment, emergency channel transportation, lighting and other emergency facilities in the power supply line where fire resistance is required.

Flame retardant grades of radiation cross-linked low-smoke halogen-free cables

According to the test conditions specified in GB/T18380.3-2002, the flame retardant grades of irradiated low-smoke halogen-free cables are divided into four grades: A, B, C, and DFlame retardant grade

Fire temperature

Fire time

The volume of non-metallic materials for laying cables in bundles

Charring height

Self-extinguishing time

A

≥815℃

40min

≥7L/m

≤2.5m

≤1h

B

≥815℃

40min

≥3.5L/m

≤2.5m

≤1h

C

≥815℃

20min

≥1.5L/m

≤2.5m

≤1h

D

≥815℃

20min

≥0.5L/m

≤2.5m

≤1h

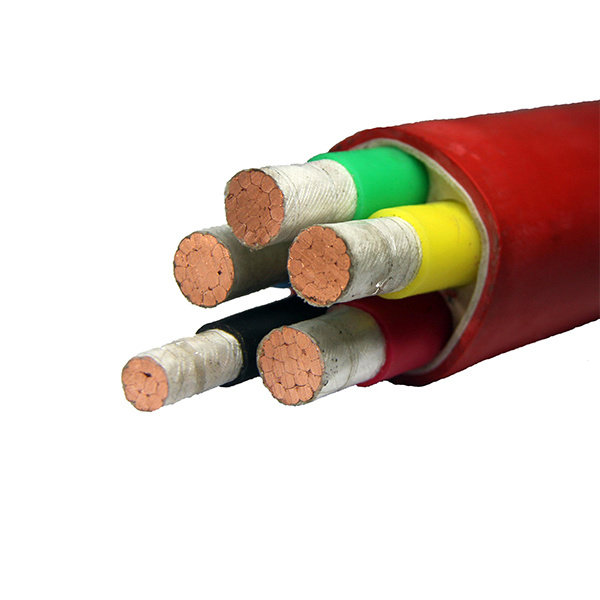

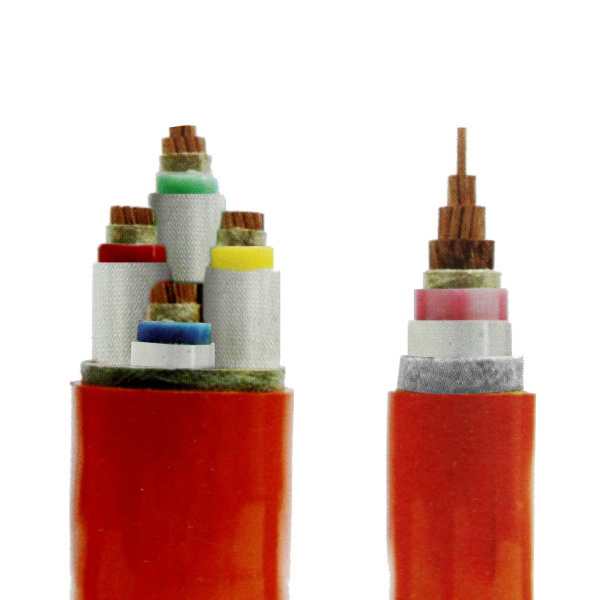

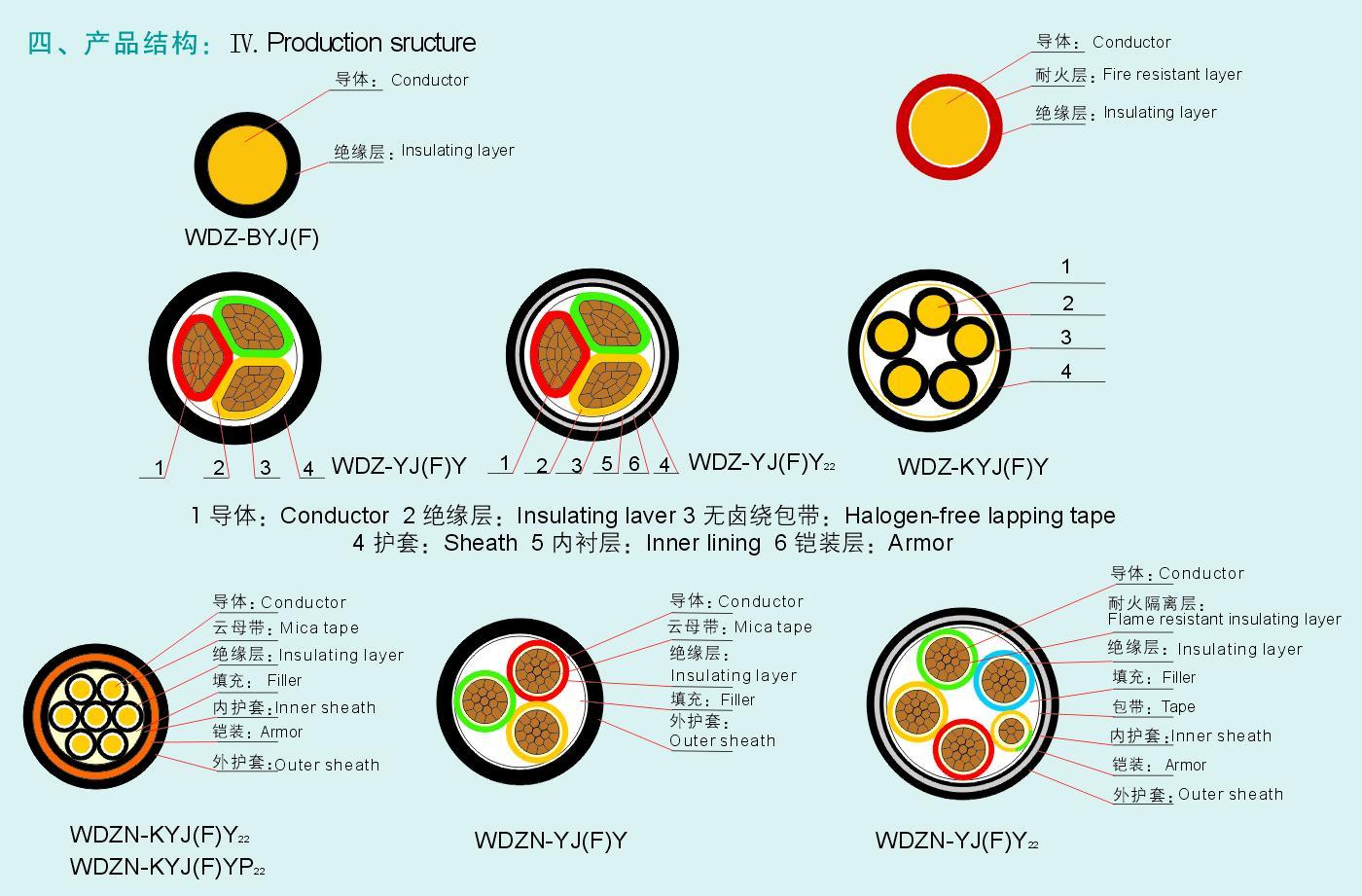

Product structure:

-

Irradiation cross-linked low-smoke halogen-free cable product representation method

The model of the radiation cross-linked low-smoke halogen-free cable is composed of two parts: the combustion characteristic code and the cable modelCode of combustion characteristics

Name

Code name

Flame retardant Class A

ZA

Flame retardant grade B

ZB

Flame retardant C grade

ZC

Flame retardant Class D

ZD

Refractory

N

Halogen-free and low-smoke

WD

Use code

Name

Code name

Electricity

Omitted

Control

K

Wiring

B

Material code

Name

Code name

Copper conductor

Omit

Irradiation cross-linked polyethylene insulation

YJ(F)

Polyolefin sheath

Y(E)

The allowable working temperature of the irradiated low-smoke halogen-free wire and cable can be 90℃, 105℃, 125℃, 135℃, etc., when indicating the temperature grade 105℃, 125℃, 135℃, 90℃ after the model. Can be omitted.

Products are expressed by model, rated voltage, core number, nominal cross section and the number of this standard.

For example:

Rated voltage 600/1000V irradiated cross-linked polyethylene insulated polyolefin sheathed flame-retardant type B low-smoke halogen-free cable, 3-core, 240mm2

Denoted as WDZB-YJ(F)Y 600/1000V 3*240 Q/TEC16.06-2005.

Rated voltage 600/1000V irradiation cross-linked polyethylene insulated polyolefin sheathed flame-retardant type B fire-resistant low-smoke halogen-free cable, 3-core 240mm2

Denoted as WDZBN-YJ(F)Y 600/1000V 3*240 Q/TEC16.06-2005.

Rated voltage 450/750V Irradiation cross-linked polyethylene insulated polyolefin sheathed flame-retardant type B low-smoke halogen-free control cable, 7 cores, 1.5mm2

Expressed as: WDZB-KYJ(F)Y 450/750V 7*1.5 Q/TEC16.06-2005.The model and name of the cable

Type Number

First name Name

Flame retardant level

Number of cores

Section

Rated voltage

WDZ-BYJ(F)

Copper core irradiated cross-linked polyethylene insulated low-smoke halogen-free flame-retardant wire and cable

B, C, D

1

1-400

450/750V

WDZ-BYJ(F)R

Copper core radiation cross-linked polyethylene insulated low-smoke halogen-free flame-retardant flexible wire

B, C, D

1

1-70

450/750V

WDZN-BYJ(F)

Copper core irradiated cross-linked polyethylene insulated low-smoke halogen-free flame-retardant fire-resistant wire and cable

B, C, D

1

1-400

450/750V

WDZN-BYJ(F)R

Copper core irradiated cross-linked polyethylene insulated low-smoke halogen-free flame-retardant fire-resistant flexible cable

B, C, D

1

1-70

450/750V

WDZ-KYJ(F)Y

(WDZ-KYJ(F)E)Irradiation cross-linked polyethylene insulated polyolefin sheathed low-smoke halogen-free flame-retardant control cable

A, B, C, D

2-61

1-10

450/750

WDZ-KYJ(F)Y22

(WDZ-KYJ(F)E22)Irradiation cross-linked polyethylene insulated steel tape armored polyolefin sheathed low-smoke halogen-free flame-retardant control cable

A, B, C, D

2-61

1-10

450/750

WDZN-KYJ(F)Y

(WDZN-KYJ(F)E)Irradiation cross-linked polyethylene insulated polyolefin sheathed low-smoke halogen-free flame-retardant fire-resistant control cable

A, B, C, D

2-61

1-10

450/750

WDZN-KYJ(F)Y22

(WDZN-KYJ(F)E22)Irradiation cross-linked polyethylene insulated steel tape armored polyolefin sheathed low-smoke halogen-free flame-retardant fire-resistant control cable

A, B, C, D

2-61

1-10

450/750

WDZ-YJ(F)Y

(WDZ-YJ(F)E)Irradiation cross-linked polyethylene insulated polyolefin sheathed low-smoke halogen-free flame-retardant power cable

A, B, C, D

1-5

1.5-800

600/1000

WDZ-YJ(F)Y22

(WDZ-YJ(F)E22)Irradiation cross-linked polyethylene insulated steel tape armored polyolefin sheathed low-smoke halogen-free flame-retardant power cable

A, B, C, D

1-5

1.5-400

600/1000

WDZN-YJ(F)Y

(WDZN-YJ(F)E)Irradiation cross-linked polyethylene insulated polyolefin sheathed low-smoke halogen-free flame-retardant fire-resistant power cable

A, B, C, D

1-5

1.5-800

600/1000

WDZN-YJ(F)Y22

(WDZN-YJ(F)E22)Irradiation cross-linked polyethylene insulated steel tape armored polyolefin sheathed low-smoke halogen-free flame-retardant fire-resistant power cable

A, B, C, D

1-5

1.5-400

600/1000

-

Using features

The rated voltage U0/U of the power cable is 0.6/1KV. The rated voltage U0/U of the control cable is 450/750V, and the rated voltage U0/U of the wire and cable is U0/U and below.

The long-term allowable working temperature of the cable does not exceed 135℃

The ambient temperature during installation should not be lower than 0°C.

Minimum bending radius during cable installation:

Control cables: cables without armor layers should be no less than 6 times the outer diameter of the cables, cables with armored or copper tape shielding structures should be no less than the outer diameter of the cables 12 times.

The minimum bending radius of the power cable is shown in Table 3item item

Single core cable

Multi-core cable

Unarmored

Armored

Unarmored

Armored

Minimum bending radius during installation

20D

15D

15D

12D

D-Outer diameter of cable

Nominal cross-section of neutral conductor of multi-core cable

Main insulated core conductor

Nominal section mm2Nominal cross section of neutral conductor mm2

3+1, 3+2, 4+1 core

4, 5 cores

4

2.5

4

6

4

6

10

6

10

16

10

16

25

16

25

35

16

35

50

25

50

70

35

70

95

50

95

120

70

120

150

70

150

185

95

185

240

120

240

300

150

300

400

185

400

Single-core cable conductive core is round, 16mm2 and above can be pressed tightly. For multi-core cables with a cross-section of 35mm2 and below, the core should be round, and those with a cross-section of 50mm2 and above should be fan-shaped, tile-shaped or semicircular. The fourth core (neutral core) in a four-core cable can be round or fan-shaped. The neutral wire of a five-core cable can be round or tile-shaped. Those with a diameter of 6mm2 and below are allowed to be composed of a single conductor, and those with a diameter of 10mm2 and above are composed of multiple single wires. The shaped conductor (sector, tile or semicircle) should be tightly pressed.

Main performance

1. Irradiated low-smoke halogen-free flame retardant

The flame retardant performance should be able to pass the GBGB18380 bundled cable burning test. After the test, the height of the cable scorch or the affected part should not exceed 2.5m above the flame point.

The halogen acid gas release test should be able to pass the determination of the total amount of halogen acid gas in GB/T17650.1-1998∠5mg/g and GB/T17650.2-19981 to measure the PH value and conductivity Rate to determine the acidity of the gas (PH in 1L of water≥4.3 The conductivity value should not exceed 10us/mm)

The smoke density test should be able to pass the determination of the smoke density of GB/T17651.1.2-1998 cable or optical cable burning under specific conditions (the minimum light transmittance≥60%) < br /> Conductor DC resistance meets the requirements of GB/T3956

Power frequency withstand voltage test: power cables should withstand 3500V for 5 minutes without breakdown, and control cables should withstand 3000V without breakdown for 5 minutes. Wire and cable should withstand 2500V, 5min without breakdown

Should withstand -15℃ low temperature winding test or low temperature impact test. After the test, there should be no visible cracks on the surface of the sample.

2. Irradiated low-smoke halogen-free flame-retardant and fire-resistant

In addition to meeting the performance of low-smoke halogen-free combustion type, its fire resistance test should be able to pass the requirements of GB/T19216-2003 cable or optical cable line integrity test under flame conditions. Burning at 750℃ 90min, 2A fuse does not blow. -

Table 5 Copper core irradiated cross-linked polyethylene insulated low-smoke halogen-free flame-retardant wire and cable structure parameters

Section mm2

Structure

Theoretical outer diameter mm

Theoretical weight kg/km

The conductor resistance at 20℃ is not greater than Ω/km

Number of roots/diameter

Insulation thickness mm

WDZ-BYJ (F)

WDN-BYJ (F)

WDZ-BYJ (F)

WDN-BYJ (F)

1*1.0

1/1.13

0.6

2.3

3.0

14.8

19.5

18.1

1*1.0

7/0.43

0.6

2.5

3.1

15.4

20.3

18.1

1*1.5

1/1.38

0.7

2.8

3.4

21.6

27.1

12.1

1*1.5

7/0.52

0.7

3.0

3.6

22.4

28.2

12.1

1*2.5

1/1.78

0.8

3.4

4.0

33.9

40.5

7.41

1*2.5

7/0.68

0.8

3.6

4.3

35.3

42.3

7.41

1*4

1/2.25

0.8

3.9

4.5

49.3

56.7

4.61

1*4

7/0.85

0.8

4.2

4.8

51.1

59.0

4.61

1*6

1/2.76

0.8

4.4

5.0

69.4

77.7

3.08

1*6

7/1.04

0.8

4.7

5.4

71.6

80.5

3.08

1*10

7/1.35

1

6.1

6.7

118.3

129.6

1.83

1*16

7/1.7

1

7.2

7.8

178.6

191.8

1.15

1*25

7/2.14

1.2

8.8

9.5

276.2

292.3

0.727

1*35

7/2.52

1.2

10.0

10.6

373.7

391.8

0.524

1*50

19/1.78

1.4

11.7

12.3

530.5

551.7

0.387

1*70

19/2.14

1.4

13.5

14.1

724.3

748.7

0.268

1*95

19/2.52

1.6

15.8

16.4

981.5

1009.9

0.193

1*120

37/2.03

1.6

17.4

18.1

1220.5

1251.7

0.153

1*150

37/2.25

1.8

19.4

20.0

1525.5

1560.1

0.124

1*185

37/2.52

2

21.6

22.3

1883.2

1921.9

0.0991

1*240

61/2.25

2.2

24.7

25.3

2434.3

2478.2

0.0754

1*300

61/2.52

2.4

27.5

28.1

3034.1

3083.0

0.0601

1*400

61/2.89

2.6

31.2

31.9

4012.3

4067.8

0.0470

Table 6 Soft copper core radiation cross-linked polyethylene insulated low-smoke halogen-free flame-retardant wire and cable structure parameters

Section mm2

Structure

Theoretical outer diameter mm

Theoretical weight kg/km

The conductor resistance at 20℃ is not greater than Ω/km

Number of roots/diameter

Insulation thickness

WDZ-BYJ(F)

WDN-BYJ(F)

WDZ-BYJ(F)

WDN-BYJ(F)

1

7/0.43

0.6

2.7

3.2

18.1

22.5

18.1

1.5

7/0.52

0.6

2.9

3.5

22.9

28.1

12.1

2.5

19/0.41

0.6

3.4

4.0

34.6

40.6

7.41

4

19/0.52

0.7

4.2

4.6

53.9

58.4

4.61

6

19/0.64

0.7

4.8

5.4

76.2

84.6

3.08

10

49/0.52

0.9

6.8

7.0

130.0

133.0

1.83

16

49/0.64

0.9

7.9

8.5

195.3

208.6

1.15

25

98/0.58

1.0

9.6

9.9

297.3

307.3

0.727

35

133/0.58

1.0

11.2

11.8

406.0

424.7

0.524

50

133/0.68

1.2

13.2

13.4

578.9

584.7

0.387

70

189/0.68

1.2

15.7

16.3

793.9

819.8

0.268

Table 7 WDZ-KYJ(F)Y irradiation cross-linked polyethylene insulated polyolefin sheathed low-smoke halogen-free flame-retardant control cable

Number of cores*Section mm2

Structure

Outer diameter mm

Theoretical weight kg/km

Number of cores*Section mm2

Structure

Outer diameter mm

Theoretical weight kg/km

Number of cores*Section mm2

Structure

Outer diameter mm

Theoretical weight kg/km

2*1.5

1/1.38

8.4

106

7*1.5

1/1.38

11.1

233

14*1.5

1/1.38

15.7

443

2*1.5

7/0.52

8.7

116

7*1.5

7/0.52

11.7

244

14*1.5

7/0.52

16.5

463

2*2.5

1/1.78

9.2

139

7*2.5

1/1.78

12.9

338

14*2.5

1/1.78

17.4

607

2*2.5

7/0.68

9.7

146

7*2.5

7/0.68

13.7

360

14*2.5

7/0.68

18.6

636

2*4

1/2.25

10.1

177

7*4.0

1/2.25

14.4

459

14*4.0

1/2.25

19.9

863

2*4

7/0.85

10.7

189

7*4.0

7/0.85

15.3

479

14*4.0

7/0.85

21.2

899

2*6

1/2.76

11.1

229

7*6.0

1/2.76

15.9

613

14*6.0

1/2.76

22.2

1165

2*6

7/1.04

11.8

248

7*6.0

7/1.04

17.0

638

14*6.0

7/1.04

23.8

1210

3*1.5

1/1.38

8.8

135

8*1.5

1/1.38

12.6

285

16*1.5

1/1.38

16.5

494

3*1.5

7/0.52

9.2

140

8*1.5

7/0.52

13.2

298

16*1.5

7/0.52

17.3

516

3*2.5

1/1.78

9.6

176

8*2.5

1/1.78

13.9

382

16*2.5

1/1.78

18.7

701

3*2.5

7/0.68

10.2

185

8*2.5

7/0.68

14.8

401

16*2.5

7/0.68

20.0

734

3*4

1/2.25

10.7

230

8*4.0

1/2.25

15.4

520

19*1.5

1/1.38

17.3

566

3*4

7/0.85

11.3

242

8*4.0

7/0.85

16.4

542

19*1.5

7/0.52

18.2

591

3*6.0

1/2.76

12.4

328

8*6.0

1/2.76

17.5

715

19*2.5

1/1.78

19.7

807

3*6.0

7/1.04

13.1

342

8*6.0

7/1.04

18.7

746

19*2.5

7/0.68

21.0

845

4*1.5

1/1.38

9.5

164

10*1.5

1/1.38

14.5

350

24*1.5

1/1.38

20.5

724

4*1.5

7/0.52

9.9

171

10*1.5

7/0.52

15.2

365

24*1.5

7/0.52

21.6

757

4*2.5

1/1.78

10.5

217

10*2.5

1/1.78

16.1

470

24*2.5

1/1.78

22.9

1002

4*2.5

7/0.68

11.1

228

10*2.5

7/0.68

17.2

495

24*2.5

7/0.68

24.4

1049

4*4.0

1/2.25

12.2

311

10*4.

1/2.25

18.4

663

27*1.5

1/1.38

20.9

793

4*4.0

7/0.85

12.9

324

10*4.0

7/0.85

19.6

692

27*1.5

7/0.52

22.0

828

4*6.0

1/2.76

13.4

411

10*6.0

1/2.76

20.4

884

27*2.5

1/1.78

23.4

1103

4*6.0

7/1.04

14.3

428

10*6.0

7/1.04

21.9

925

27*2.5

7/0.68

25.0

1154

5*1.5

1/1.38

10.3

175

12*1.5

1/1.38

14.9

393

30*1.5

1/1.38

21.6

865

5*1.5

7/0.52

10.8

183

12*1.5

7/0.52

15.7

410

30*1.5

7/0.52

22.8

903

5*2.5

1/1.78

12.0

260

12*2.5

1/1.78

16.6

535

30*2.5

1/1.78

24.2

1207

5*2.5

7/0.68

12.7

272

12*2.5

7/0.68

17.7

561

30*2.5

7/0.68

25.9

1263

5*4.0

1/2.25

13.3

349

12*4.0

1/2.25

19.0

758

37*1.5

1/1.38

23.3

1033

5*4.0

7/0.85

14.1

363

12*4.0

7/0.85

20.2

791

37*1.5

7/0.52

24.5

1078

5*6.0

1/2.76

14.6

463

12*6.0

1/2.76

21.1

1019

37*2.5

1/1.78

26.1

1451

5*6.0

7/1.04

15.6

480

12*6.0

7/1.04

22.6

1060

37*2.5

7/0.68

27.9

1517

Table 8 WDZN-KYJ(F)Y irradiated cross-linked polyethylene insulated polyolefin sheathed low-smoke halogen-free flame-retardant fire-resistant power control cable

Number of cores*Section mm2

Structure

Outer diameter mm

Theoretical weight kg/km

Number of cores*Section mm2

Structure

Outer diameter mm

Theoretical weight kg/km

Number of cores*Section mm2

Structure

Outer diameter mm

Theoretical weight kg/km

2*1.5

1/1.38

10.0

165

7*1.5

1/1.38

13.5

284

14*1.5

1/1.38

18.9

542

2*1.5

7/0.52

10.4

186

7*1.5

7/0.52

14.0

297

14*1.5

7/0.52

19.7

566

2*2.5

1/1.78

10.8

210

7*2.5

1/1.78

15.3

397

14*2.5

1/1.78

20.7

715

2*2.5

7/0.68

11.4

217

7*2.5

7/0.68

16.0

422

14*2.5

7/0.68

21.8

750

2*4

1/2.25

11.8

249

7*4.0

1/2.25

16.7

523

14*4.0

1/2.25

23.1

985

2*4

7/0.85

12.4

258

7*4.0

7/0.85

17.6

546

14*4.0

7/0.85

24.5

1028

2*6

1/2.76

12.8

299

7*6.0

1/2.76

18.2

682

14*6.0

1/2.76

25.4

1298

2*6

7/1.04

13.5

310

7*6.0

7/1.04

19.3

711

14*6.0

7/1.04

27.0

1332

3*1.5

1/1.38

10.6

196

8*1.5

1/1.38

15.1

355

16*1.5

1/1.38

19.9

605

3*1.5

7/0.52

11.0

203

8*1.5

7/0.52

15.7

370

16*1.5

7/0.52

20.7

631

3*2.5

1/1.78

11.4

248

8*2.5

1/1.78

16.4

457

16*2.5

1/1.78

22.2

826

3*2.5

7/0.68

12.0

258

8*2.5

7/0.68

17.3

479

16*2.5

7/0.68

23.4

866

3*4

1/2.25

12.4

304

8*4.0

1/2.25

18.0

604

19*1.5

1/1.38

20.9

695

3*4

7/0.85

13.1

316

8*4.0

7/0.85

18.9

630

19*1.5

7/0.52

21.8

726

3*6.0

1/2.76

14.1

412

8*6.0

1/2.76

20.0

808

19*2.5

1/1.78

23.3

952

3*6.0

7/1.04

14.9

427

8*6.0

7/1.04

21.2

844

19*2.5

7/0.68

24.6

998

4*1.5

1/1.38

11.5

237

10*1.5

1/1.38

17.5

442

24*1.5

1/1.38

24.7

890

4*1.5

7/0.52

11.9

249

10*1.5

7/0.52

18.2

461

24*1.5

7/0.52

25.8

929

4*2.5

1/1.78

12.4

293

10*2.5

1/1.78

19.1

569

24*2.5

1/1.78

27.1

1183

4*2.5

7/0.68

13.0

305

10*2.5

7/0.68

20.1

596

24*2.5

7/0.68

28.7

1240

4*4.0

1/2.25

14.2

409

10*4.

1/2.25

21.4

779

27*1.5

1/1.38

25.2

976

4*4.0

7/0.85

14.9

425

10*4.0

7/0.85

22.6

813

27*1.5

7/0.52

26.4

1019

4*6.0

1/2.76

15.4

504

10*6.0

1/2.76

23.4

1008

27*2.5

1/1.78

27.7

1303

4*6.0

7/1.04

16.3

523

10*6.0

7/1.04

24.8

1055

27*2.5

7/0.68

29.3

1365

5*1.5

1/1.38

12.4

286

12*1.5

1/1.38

18.0

480

30*1.5

1/1.38

26.1

1065

5*1.5

7/0.52

12.9

295

12*1.5

7/0.52

18.8

501

30*1.5

7/0.52

27.3

1112

5*2.5

1/1.78

14.1

373

12*2.5

1/1.78

19.7

630

30*2.5

1/1.78

28.7

1427

5*2.5

7/0.68

14.8

413

12*2.5

7/0.68

20.7

660

30*2.5

7/0.68

30.4

1496

5*4.0

1/2.25

15.4

490

12*4.0

1/2.25

22.0

865

37*1.5

1/1.38

28.1

1274

5*4.0

7/0.85

16.2

508

12*4.0

7/0.85

23.3

903

37*1.5

7/0.52

29.4

1330

5*6.0

1/2.76

16.8

606

12*6.0

1/2.76

24.1

1135

37*2.5

1/1.78

30.9

1716

5*6.0

7/1.04

17.7

628

12*6.0

7/1.04

25.6

1182

37*2.5

7/0.68

32.8

1798

Table 9 WDZ-YJ(F)Y Irradiation cross-linked polyethylene insulated polyolefin sheathed low-smoke halogen-free flame-retardant power cable

Specifications

Number of cores*Section mm2Theoretical outer diameter mm

Theoretical weight kg/km

Specifications

Number of cores*Section mm2Theoretical outer diameter mm

Theoretical weight kg/km

Specifications

Number of cores*Section mm2Theoretical outer diameter mm

Theoretical weight kg/km

1*1.5

5.6

54

3*35

23.4

1361

3*10+1*6

16.4

565

1*2.5

6.0

68

3*50

23.6

1768

3*16+1*10

18.5

807

1*4

6.5

87

3*70

27.0

2393

3*25+1*16

22.3

1225

1*6

7.0

111

3*95

30.1

3147

3*35+1*16

24.1

1529

1*10

8.3

162

3*120

33.5

3932

3*50+1*25

25.9

2063

1*16

9.0

225

3*150

37.3

4919

3*70+1*35

29.9

2806

1*25

10.6

331

3*185

41.3

6044

3*95+1*50

33.8

3744

1*35

11.6

434

3*240

46.7

7771

3*120+1*70

37.4

4734

1*50

13.2

594

4*1.5

10.7

193

3*150+1*70

41.2

5721

1*70

15.1

811

4*2.5

11.7

245

3*185+1*95

46.2

7127

1*95

16.8

1068

4*4

12.8

319

3*240+1*120

51.9

9113

1*120

18.5

1324

4*6

14.0

415

3*300+1*150

57.5

11291

1*150

20.6

1653

4*10

17.2

615

3*2.5+2*1.5

12.2

265

1*185

22.8

2032

4*16

19.0

865

3*4+2*2.5

13.3

343

1*240

25.4

2583

4*25

23.2

1329

3*6+2*4

14.7

453

1*300

30.1

3237

4*35

25.6

1734

3*10+2*6

17.3

651

1*400

33.7

4270

4*50

26.2

2302

3*16+2*10

20.3

948

1*500

38.0

5313

4*70

30.5

3146

3*25+2*16

23.7

1418

1*630

42.1

6658

4*95

34.4

4145

3*35+2*16

25.4

1720

1*800

46.9

8372

4*120

38.0

5200

3*50+2*25

26.2

2317

2*1.5

9.6

130

4*150

42.3

6481

3*70+2*35

30.4

3156

2*2.5

10.4

159

4*185

46.9

7966

3*95+2*50

34.1

4236

2*4

11.3

204

4*240

53.1

10245

3*120+2*70

37.3

5415

2*6

12.3

259

4*300

59.4

12702

3*150+2*70

41.8

6412

2*10

14.9

385

5*1.5

11.5

226

3*185+2*95

46.9

8063

2*16

16.4

514

5*2.5

12.6

290

3*240+2*120

52.7

10273

2*25

20.0

754

5*4

13.9

385

4*2.5+1*1.5

12.4

277

2*35

22.0

965

5*6

15.2

499

4*4+1*2.5

13.6

361

2*50

20.2

1220

5*10

18.7

745

4*6+1*4

15.0

476

2*70

23.0

1642

5*16

20.7

1054

4*10+1*6

18.0

695

2*95

24.8

2132

5*25

25.5

1625

4*16+1*10

20.7

1003

2*120

27.4

2653

5*35

28.4

2144

4*25+1*16

24.6

1522

2*150

30.7

3306

5*50

28.9

2862

4*35+1*16

26.8

1924

2*185

34.2

4080

5*70

33.9

3916

4*50+1*25

26.6

2578

2*240

38.4

5209

5*95

38.1

5178

4*70+1*35

31.1

3540

3*1.5

10.0

162

5*120

41.7

6468

4*95+1*50

34.8

4696

3*2.5

10.8

202

5*150

46.4

8084

4*120+1*70

37.8

5923

3*4

11.9

258

5*185

52.1

9971

4*150+1*70

43.0

7256

3*6

13.0

329

5*240

58.3

12769

4*185+1*95

48.1

9033

3*10

15.7

487

3*2.5+1*1.5

11.4

232

4*240+1*120

54.1

11544

3*16

17.4

678

3*4+1*2.5

12.5

300

3*25

21.2

1053

3*6+1*4

13.7

387

Table 10 WDZ-YJ(F)Y22 irradiated cross-linked polyethylene insulated steel tape armored polyolefin sheathed low-smoke halogen-free power cable

Specifications

Number of cores*Section mm2Theoretical outer diameter mm

Theoretical weight kg/km

Specifications

Number of cores*Section mm2Theoretical outer diameter mm

Theoretical weight kg/km

Specifications

Number of cores*Section mm2Theoretical outer diameter mm

Theoretical weight kg/km

2*1.5

12.8

264

4*10

20.4

846

3*50+1*25

30.7

2722

2*2.5

13.6

304

4*16

22.2

1120

3*70+1*35

34.7

3560

2*4

14.5

361

4*25

26.4

1638

3*95+1*50

38.5

4568

2*6

15.5

429

4*35

29.0

2091

3*120+1*70

42.5

5691

2*10

18.1

587

4*50

29.6

2659

3*150+1*70

46.4

6797

2*16

19.6

736

4*70

35.3

3881

3*185+1*95

51.7

8358

2*25

23.2

1022

4*95

39.3

4988

3*240+1*120

57.7

10522

2*35

25.2

1259

4*120

42.9

6105

3*2.5+2*1.5

15.4

432

2*50

23.4

1490

4*150

47.5

7535

3*4+2*2.5

16.5

526

2*70

26.2

1949

4*185

52.3

9156

3*6+2*4

17.9

653

2*95

28.2

2477

4*240

58.5

11584

3*10+2*6

20.5

885

2*120

32.2

3331

4*300

64.9

14227

3*16+2*10

23.5

1220

2*150

35.5

4059

5*1.5

14.7

386

3*25+2*16

26.9

1734

2*185

38.8

4891

5*2.5

15.8

463

3*35+2*16

28.8

2073

2*240

43.4

6164

5*4

17.1

575

3*50+2*25

29.6

2680

3*1.5

13.2

302

5*6

18.4

706

3*70+2*35

35.2

3904

3*2.5

14.0

353

5*10

21.9

997

3*95+2*50

38.9

5067

3*4

15.1

422

5*16

23.9

1332

3*120+2*70

42.3

6344

3*6

16.2

507

5*25

28.9

1979

3*150+2*70

47.0

7475

3*10

18.9

701

5*35

33.0

2824

3*185+2*95

52.1

9246

3*16

20.6

912

5*50

33.5

3555

3*240+2*120

58.1

11629

3*25

24.4

1337

5*70

38.7

4744

4*2.5+1*1.5

15.6

448

3*35

26.6

1672

5*95

42.9

6100

4*4+1*2.5

16.8

547

3*50

26.8

2082

5*120

46.9

7527

4*6+1*4

18.2

679

3*70

31.8

3061

5*150

51.6

9256

4*10+1*6

21.2

938

3*95

34.9

3887

5*185

57.7

11347

4*16+1*10

23.9

1281

3*120

38.3

4750

5*240

64.1

14335

4*25+1*16

28.0

1864

3*150

42.1

5823

3*2.5+1*1.5

14.6

391

4*35+1*16

31.6

2587

3*185

46.5

7093

3*4+1*2.5

15.7

472

4*50+1*25

31.4

3258

3*240

51.9

8951

3*6+1*4

16.9

574

4*70+1*35

35.7

4306

4*1.5

13.9

342

3*10+1*6

19.6

786

4*95+1*50

39.8

5594

4*2.5

14.9

407

3*16+1*10

21.7

1056

4*120+1*70

43.0

6921

4*4

16.0

495

3*25+1*16

25.5

1522

4*150+1*70

48.4

8411

4*6

17.2

607

3*35+1*16

27.3

1849

4*185+1*95

53.5

10318

4*240+1*120

59.9

13050

-

Delivery length

Irradiated low-smoke halogen-free wire; the length of the coil is 100 meters, the length of the coil should not be less than 100 meters, and the measurement error should not exceed ±5%. For short-segment deliveries with a length of not less than 20 meters, the quantity should not exceed 10% of the total delivery length, and the short-sized quantity in each piece should not exceed 5. According to the agreement between the two parties, delivery of any length is allowed.

Irradiated low-smoke halogen-free power cables and control cables: the delivery length should be no less than 100m, and the measurement error should be no more than 0.5%. According to the agreement between the two parties, the delivery of cables of any length is allowed.

packaging and transportation signs

The cable should be properly packaged on a cable reel for delivery. The length of the cable extension should not be less than 300mm, and the end should be reliably sealed with a cable jacket.

Each cable package should be accompanied by a product quality certificate. The certificate should be placed in an impermeable bag and fixed on the side of the cable reel.

The outside of each cable reel shall be marked:

a. Name or trademark of manufacturer

b. Cable model and specification

c, length m

d. Date of manufacture: Year Month

e, standard number

f, gross weight kg:

g, a symbol indicating the correct direction of rotation of the cable reel

Transportation and storage

a. The wire reel is not allowed to lay flat

b. It is strictly forbidden to drop the cable reel with cables from a high place during transportation, and it is strictly forbidden to damage the cables mechanically.

c. It is strictly forbidden to hoist several trays at the same time when hoisting packages. On vehicles, ships and other transportation tools, the cable reel must be placed firmly and fixed with a suitable method to prevent mutual collision or overturning.

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!