BTTZ / BTTVZ / BTTQ / BTTVQ / WD-BTTYZ / WD-BTTYQ

Mineral insulated cable (Mineral Insulated Cable) is abbreviated as MI cable. When used as wiring, it is customarily called magnesium oxide cable or fire-resistant cable in China. Mineral insulated cables were developed earlier in foreign countries. As early as the end of the 19th century, a Swiss engineer Arnold Francois Borel proposed the idea of mineral insulated cables, which was patented in 1896. After being put into production in France and Britain in 1934-1936, they developed rapidly. The major industrial countries, Italy, Canada, Australia, the United States, the United States, the Soviet Union, and Japan, have been developed and put into production one after another. my country also developed and produced in the 1960s, and began mass production at the end of the 20th century. In the 21st century, it entered the national fire protection design code and was widely used in China.

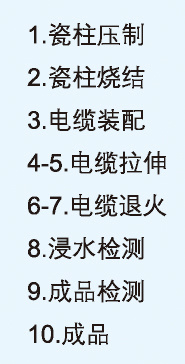

Classification:

Key words:

BTTZ / BTTVZ / BTTQ / BTTVQ / WD-BTTYZ / WD-BTTYQ

- Description

- characteristic

- process

- Standards and specifications

- Design and selection

- parameter

- enclosure

- Laying and installation

- Application

-

- Commodity name: BTTZ / BTTVZ / BTTQ / BTTVQ / WD-BTTYZ / WD-BTTYQ

Mineral insulated cable (Mineral Insulated Cable) is abbreviated as MI cable. When used as wiring, it is customarily called magnesium oxide cable or fire-resistant cable in China. Mineral insulated cables were developed earlier in foreign countries. As early as the end of the 19th century, a Swiss engineer Arnold Francois Borel proposed the idea of mineral insulated cables, which was patented in 1896. After being put into production in France and Britain in 1934-1936, they developed rapidly. The major industrial countries, Italy, Canada, Australia, the United States, the United States, the Soviet Union, and Japan, have been developed and put into production one after another. my country also developed and produced in the 1960s, and began mass production at the end of the 20th century. In the 21st century, it entered the national fire protection design code and was widely used in China.

Product overview

Mineral Insulated Cable is abbreviated as MI cable. When used as wiring, it is customarily referred to as magnesium oxide cable or fire-resistant cable in China.

Mineral insulated cables were developed earlier in foreign countries. As early as the end of the 19th century, a Swiss engineer Arnold Francois Borel proposed the idea of mineral insulated cables, which was patented in 1896. After France and the United Kingdom were put into production in 1934-1936 Rapid development, major industrial countries, Italy, Canada, Australia, the United States, the Soviet Union, and Japan have been developed and put into production one after another. Used extensively.

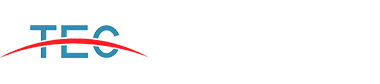

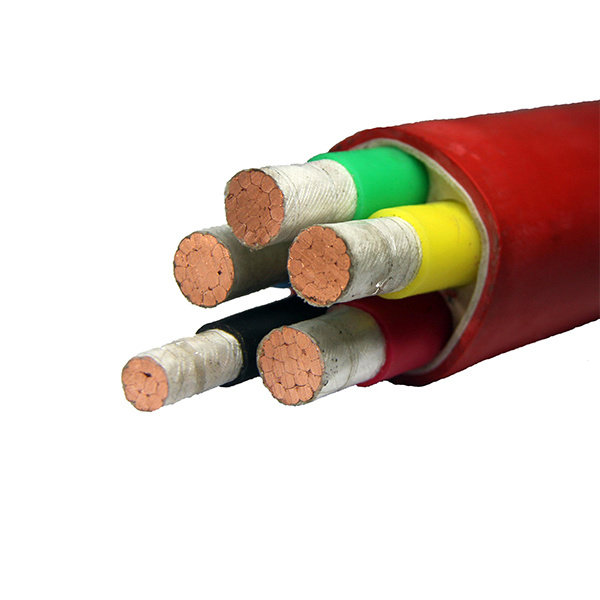

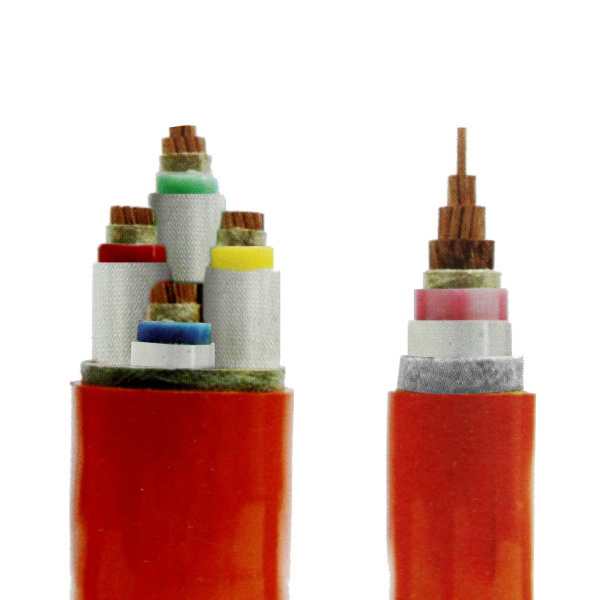

Mineral insulated cable composition

Mineral insulated cable is a cable that uses annealed copper as conductor, dense magnesium oxide as insulation, and annealed copper tube as sheath. When necessary, a plastic outer sheath is extruded on the annealed copper sheath. Special requirements For smoke-free and halogen-free occasions, a low-smoke, halogen-free sheath can be added to the outside.

The advantages of mineral insulated cables

Since all materials of this cable are made of inorganic materials, it has some advantages that other cables cannot have. Such as fire prevention, large current carrying capacity, mechanical damage resistance, halogen-free non-toxic, explosion-proof, waterproof, corrosion resistance, long life, safety, overload resistance, high temperature resistance, low cost, small bending radius, anti-termite, anti-mouse bite, copper protection Features such as protective grounding wire.

Product labeling method

Structural features Voltage level Model Name Number of cores Section mm2 Light load 500V

BTTQ Lightweight copper core copper sheathed mineral insulated cable 1, 2, 3, 4, 7 1-4 BTTVQ

Lightweight copper core copper sheathed PVC sheathed mineral insulated cable

1, 2, 3, 4, 7

1-4

WD-BTTYQ Lightweight copper core copper sheathed mineral insulated halogen-free low-smoke jacketed cable 1, 2, 3, 4, 7 1-4 Overload

750V

BTTZ

Heavy copper core copper sheathed mineral insulated cable

1, 2, 3, 4, 7, 10, 12, 19

1-400

BTTVZ

Heavy copper core copper sheathed PVC sheathed mineral insulated cable

1, 2, 3, 4, 7, 10, 12, 19

1-400

WD-BTTYZ Heavy copper core copper sheathed mineral insulated halogen-free low-smoke jacketed cable 1, 2, 3, 4, 7, 10, 12, 19 1-400 -

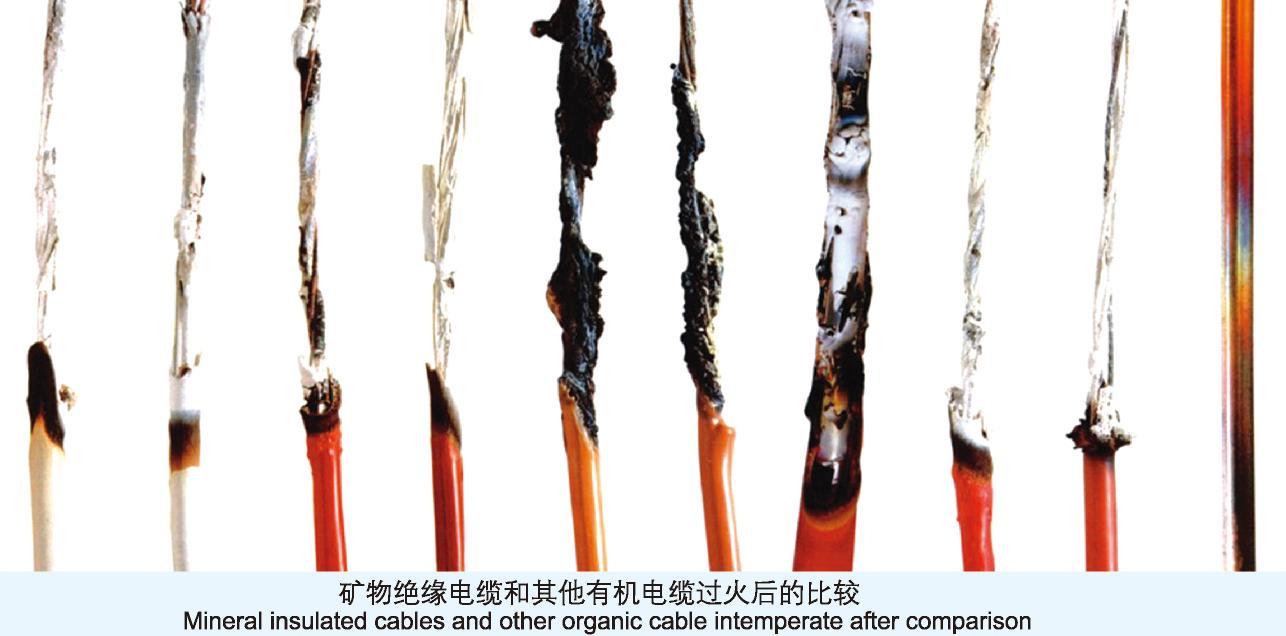

Fireproof

Because the cables are all made of inorganic materials (metallic copper and magnesium oxide powder), it will not cause fire, and cannot burn or support combustion. . Since the melting point of copper is 1083°C and the melting point of magnesium oxide is 2800°C, this kind of cable can continue to maintain power supply under fire conditions close to the melting point of copper, and is a true fireproof cable. It is currently the only safety class electricity that can maintain the power supply capacity for three hours in a 1000 ℃ fire and can withstand the impact of fire-fighting water spray and heavy objects.

High current carrying capacity

High current carrying capacityThe thermal conductivity of magnesium oxide insulation materials is much greater than that of mica insulation and organic insulation materials, and it has good heat dissipation. Therefore, for cables with the same cross-section, mineral insulated cables can carry more current than mica insulated and organic insulated cables.

Due to the relevant national regulations on fire-fighting lines: flame-retardant, fire-resistant and other organic insulated cables must be laid with protective metal pipes or closed bridges, while mineral insulated cables can be laid directly, so they can be considered more than organic insulated cables. Less derating factor naturally reduces the cross-section requirement. For lines above 16mm2, at least one cross-section can be reduced, and for places where human contact is not allowed, at least two cross-sections can be reduced.Good water resistanceThe copper sheath used in the mineral insulated cable is a seamless copper tube, and the water molecules are completely blocked out, which is a real waterproof product.

Explosion-proof

The copper sheath used in the mineral insulated cable is a seamless copper tube, and the magnesium oxide powder is tightly compacted, resulting in flammable gas, Oil vapor and flame cannot reach the electrical equipment connected to the cable, so the cable has explosion-proof characteristics.

Corrosion resistance

Copper has good corrosion resistance and does not require any additional protection under normal use. Under special environmental conditions, For example, in an environment that has a strong corrosive effect on copper, it is only necessary to add a layer of plastic outer sheath to the outside of the cable to achieve corrosion resistance, so the cable has good corrosion resistance.

High temperature resistance

Mineral insulated cables can work continuously and normally at a high temperature of 250℃, and work for a short time at 1083℃, which is close to the melting point of copper, while magnesium oxide is insulated The material will not change in any properties at this time. This feature is suitable for use in metallurgy, cement and other high-temperature environments.

Resistant to mechanical damage

The conductor and metal sheath of mineral insulated cables have certain strength and toughness. Magnesium oxide is highly compressed during cable processing. , The conductor, sheath, and insulation form a dense whole. Therefore, the sheath will not be damaged when the cable is deformed by impact, bending, flattening, torsion, etc., the relative position between the core wires and between the core wire and the sheath remains unchanged, no short circuit will occur, and the electrical performance will not be affected. .

Small bending radius, small laying spaceMineral insulated cable is a dense whole, the minimum bending radius is not more than 6D (D-cable diameter), so it is easy to install and reduce The space occupied by the line laying. It is suitable for replacing bus ducts and laying in places with small space.

Smoke-free and non-toxic

Mineral insulated cables are all composed of inorganic substances (metallic copper and magnesium oxide powder), so the cables will not ignite spontaneously even under fire conditions. Will not produce smoke and toxic gases, it is a safe and environmentally friendly cable in the true sense.

Overload resistant

Mineral insulated cables are insulated with magnesium oxide. The melting point of magnesium oxide is 2800℃. Compared with ordinary plastic cables, the current carrying capacity of mineral insulated cables It can increase a cross-section level, and can withstand considerable overload at the same time, and its overload capacity can reach more than 10 times the normal carrying capacity.

At the same time, mineral insulated cables can recover quickly after overvoltage without damaging the insulation.Long life spanThe materials used in mineral insulated cables are all inorganic materials and do not age. The service life can be calculated according to the rate of oxidation and corrosion of the copper sheath. According to the data, it takes 257 years for the sheath to oxidize 0.25mm at an ambient temperature of 250℃, while the thickness of the copper sheath of the mineral insulated cable is generally between 0.31-1.17mm, and the actual use temperature is lower than 250℃, so the cable It is a permanent cable.

The copper sheath can be used as a ground wireFor mineral insulated cables, due to the continuity of the copper sheath and extremely low grounding resistance, it can be used as a grounding conductor, which can be omitted A protective grounding wire.

-

-

1. Mineral insulated cable manufacturing standards:

1, GB/T13033-2007 rated voltage 750V and below mineral insulated cables and terminals

2, IEC60702-2002 mineral insulated cables and their terminals with a rated voltage not exceeding 750V

3, BS6207-2001 mineral insulated cables with rated voltages of 750V and below

Second, the characteristic standard of mineral insulated cables:

1, BS6387: 1994 Performance Standard for Cables Used to Keep Circuits intact under Fire Conditions (UK)

2, GA306.1~306.2-2001 Ministry of Public Security Fire Standards

3, IEC60332-3 cable burning test under flame conditions

4, GB/T18380.1-.3-2001 cable burning test under flame conditions

5, GB/T17651.2-1998 cable or optical cable burning smoke density determination under specific conditions

6, GB/T17650.2-1998 The test of gas released when the material taken from the cable burns

7, GB/T19216-2003 wire and cable fire resistance characteristic test method

8, IEC60331 wire and cable fire resistance characteristic test method

9, UL2196 cable fire resistance test (U.S.)

10, IEC60754-2 acid and corrosive gas volatilization

11, IEC60134-2 smoke density test

3. Application standards for mineral insulated cables

1, GB50045-2005 Code for fire protection design of high-rise civil buildings

2, GB50016-2006 Building Design Fire Protection Code

3, JGJ16-2008 Civil Building Electrical Design Code

4, GB50217-2007 Power Engineering Cable Design Code

5, GB50116-98 Design Specification for Automatic Fire Alarm System

6, GB50157-2003 Metro Design Specification

7, GB50067-97 Code for fire protection design of garages, repair garages, and parking lots

8, GB50333-2002 Hospital, clean operation department building technical code

9, DBJ50-054-2006 Code for Fire Protection Design of Large Commercial Buildings (Chongqing)

10, DG/TJ08-2048-2008 Civil Building Electrical Fire Protection Design Regulations

11, GY5067-2003 Radio and TV building design fire protection code

12, BS5345 is used for the customary rules for the selection, installation and maintenance of electrical devices that may have explosive gas atmospheres

13, AS2293 fire detection and alarm in buildings

14. Fire-fighting equipment and elevators in the AS300 line rules

15, GB/T16895.15-2002 Building electrical installation-wiring system current capacity

16, 09D101-6 mineral insulated cable laying

17, 08ZD02 Central South Region Building Standard Design Electrical Atlas

18, BS7671 electrical installation requirements (UK)

-

1. Design and selection method

1. Model selection

BTTZ, BTTVZ, WD-BTTYZ (heavy load) is suitable for the voltage between the core and the sheath and between the core and the core does not exceed 750V AC and DC rms occasions.

BTTQ, BTTVQ, WD-BTTYQ (light load) is suitable for the voltage between the core and the sheath and between the core and the core does not exceed 500V AC and DC rms occasions.

Mineral insulated cables with plastic sheath should be used in the following cases

1.1 The cable is laid in an environment that is corrosive to the copper sheath.

1.2 When directly burying or laying through pipes.

1.3 It is laid out in the non-technical space of the building and in places with aesthetic requirements. Where there is a fire protection requirement, a halogen-free and low-smoke plastic outer sheath should be used.

2, selection of specifications

2.1 According to the laying environment of the cable, determine the maximum operating temperature of the cable, reasonably select the corresponding cable carrying capacity, and determine the cable specification.

2.1.1 Mineral insulated cables have two options for current carrying capacity according to different cable temperatures:

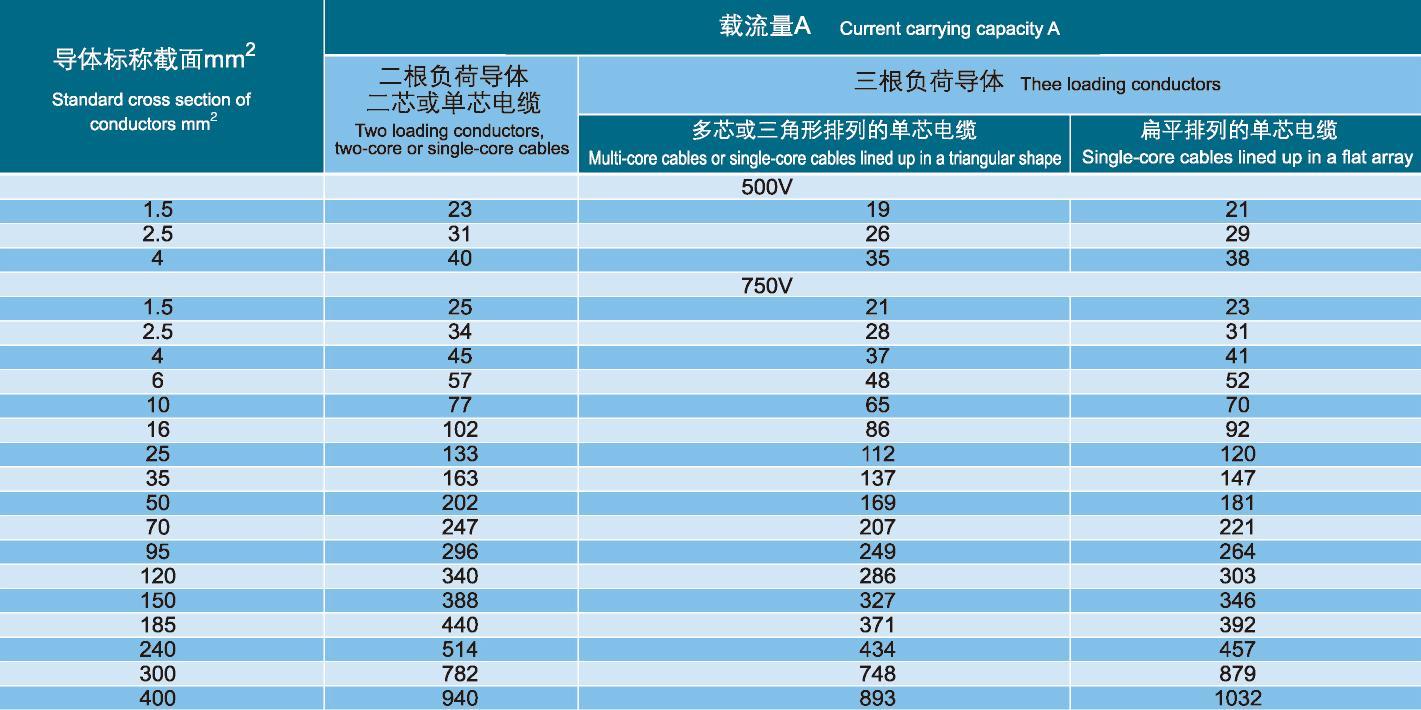

The current-carrying capacity at a temperature of 70℃ is shown in Table 1 and Table 3.

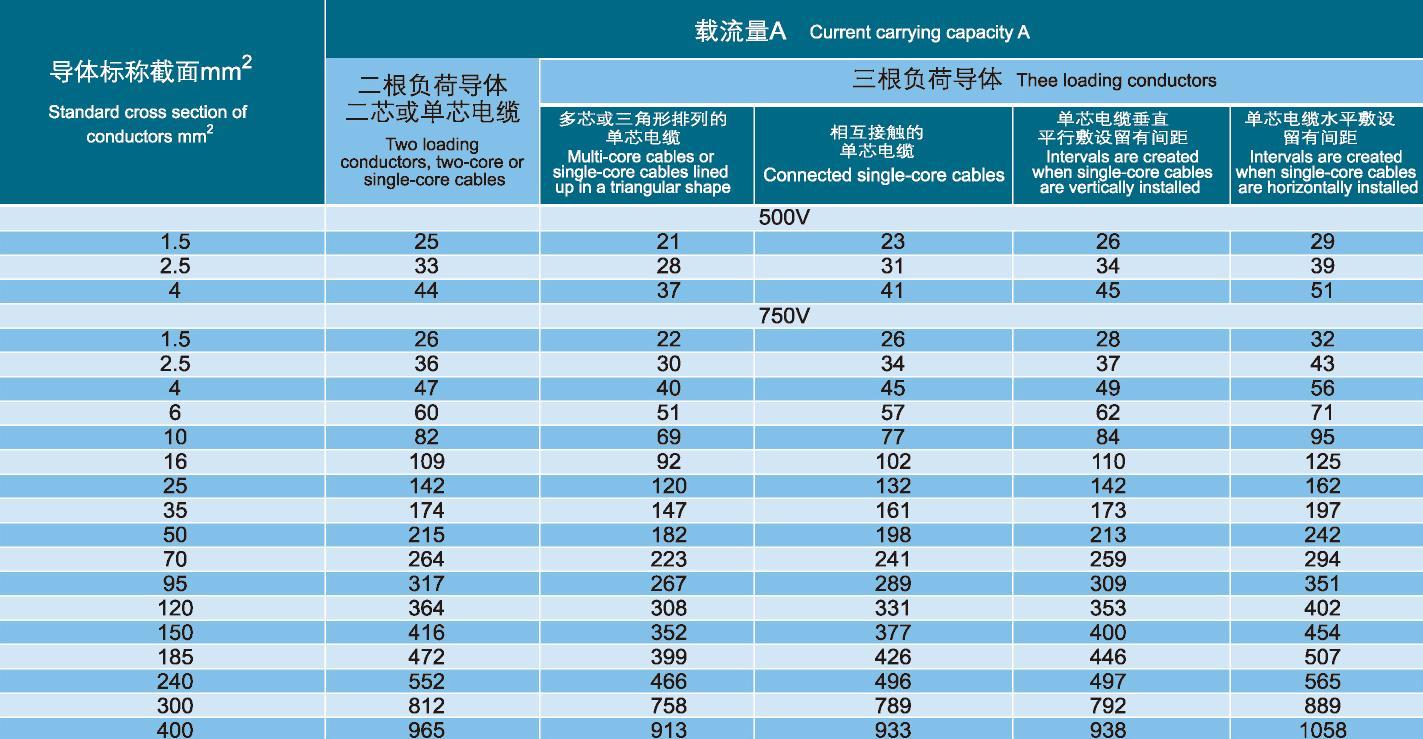

See Table 2 and Table 4 for the current-carrying capacity at 105℃.

2.1.2 Under the following laying conditions, the normal operating temperature should be 70℃, and the current carrying capacity of the cable should be selected

a. Lay open lines along walls, brackets, roofs and bridges.

b. Lines laid together with other types of cables in the same bridge frame, shaft, cable trench, and cable tunnel.

c. Other places where the temperature of the cable sheath is too high to cause personal injury or equipment damage.

2.1.3 Cables are laid separately on bridges, cable trenches, and pipes where there is no contact with the machine. The current carrying capacity can be selected according to the normal working temperature of 105℃.

2, 2 According to the actual length of the line and the length of the cable delivery, the mineral insulated cable specifications should be reasonably determined.

Because the processing length of mineral insulated cables is limited by raw materials, the delivery length of large-size single-core and multi-core cables cannot be as long as plastic cables (see P18 Cable data sheet). Therefore, the delivery length of the cable needs to be considered when selecting specifications. Avoid the use of intermediate joints as much as possible.

Example 1: Calculate the line with a load of 1000A, according to the requirement that the maximum operating temperature does not exceed 70°C. Select 400mm2 according to Table 3. The delivery length is 60 meters. If the length of the line is greater than 60 meters, 240m2 double-split connection is used, and the delivery length reaches 99 meters, which can avoid the use of intermediate connections. Longer lines also use 240m2 double-split connection. Because the longer the line, the harsher the laying conditions. It is easy to lay the cables with small specifications. Example 2: According to the calculated load, a 4x25mm2 multi-core cable is used. If the delivery length exceeds 124 meters, a 4x (1x25) single-core cable can be considered. The delivery length can reach 425 meters. No intermediate joints are required.

3. Design points:

3.1 Copper sheath can be used as PE grounding wire, so PE wire is generally not needed.

3.2 corresponds to plastic cables above 16mm2 and can be used with reduced cross-section. If the plastic cable design is 4x185+95, then the corresponding mineral insulated cable is BTTZ 4X (1X150).

3.3 Shuangpin and Duopin generally do not need to consider the coefficient.

3.4 Use large cross-section cables to replace bus ducts with double or multiple cables, which can reduce project investment and increase line safety.

3.5 Using our company's special branch junction box, the branch of the cable can be realized.

-

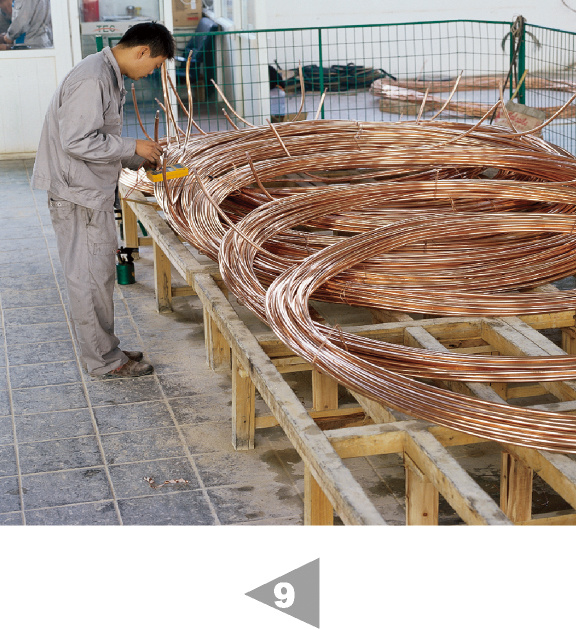

Product technical parameters

1. The rated voltage of mineral insulated cables; light load (BTTQ, BTTVQ, WD-BTTYQ) 500V and heavy load (BTTZ,

BTTVZ, WD-BTTYZ) 750V.

2, test voltage of mineral insulated cable finished product; light load 2000V/1min, heavy load 2500V/1min

3. The insulation resistance of mineral insulated cables should be greater than 1000MΩ, when the cable length is less than 100m, the insulation resistance should be greater than

10000MΩ

4. The long-term working temperature of mineral insulated cables; the long-term working temperature of mineral insulated cables is 70℃, and the long-term working temperature of mineral insulated cables is 105℃ in special high temperature occasions. The working temperature can be 250℃ and below. It can continue to supply power for more than 3 hours at 950-1000℃, and the working temperature can reach 1083℃ in a short or very short time.

5. Bending radius; mineral insulated cables allow the minimum bending radius to meet the requirements of the following table

Cable Data Sheet

Table 1 Mineral insulated cables, with plastic outer sheath or bare cables that allow access, are laid on wooden walls

Metal sheath temperature 70℃, ambient temperature: 30℃

Note:

1. The two ends of the copper sheath of the single-core cable in the loop are connected to each other.

2. The current-carrying capacity of bare sheathed cables that are allowed to be contacted should be multiplied by 0.9 according to the table.

Table 2 Mineral insulated cables do not allow people to touch bare cables laid on the brick wall

The temperature of the metal sheath is 105℃, the ambient temperature is 30℃

Note:

1. The two ends of the copper sheath of the single-core cable in the loop are connected to each other.

2. When laying in a bundle, the current-carrying capacity value of the cable does not need to be corrected.

Table 3 Mineral insulated cables, plastic outer sheaths or bare cables that allow contact to be laid in the air

Metal sheath temperature 70℃, ambient temperature: 30℃

Note:

1. The two ends of the copper sheath of the single-core cable in the loop are connected to each other.

2. The current-carrying capacity value of the bare sheathed cable that is allowed to be contacted should be multiplied by 0.9 according to the table.

3. There should be at least one cable outer diameter in the space left when laying with spacing.

Table 4 Mineral insulated cables, bare cables that are not allowed to be touched by people are laid in the air

The temperature of the metal sheath is 105℃, the ambient temperature is 30℃

Note:

1. The two ends of the copper sheath of the single-core cable in the loop are connected to each other.

2. When laying in bundles, the ampacity does not need to be corrected.

3. When laying with spacing, the spacing should be at least the outer diameter of one cable.

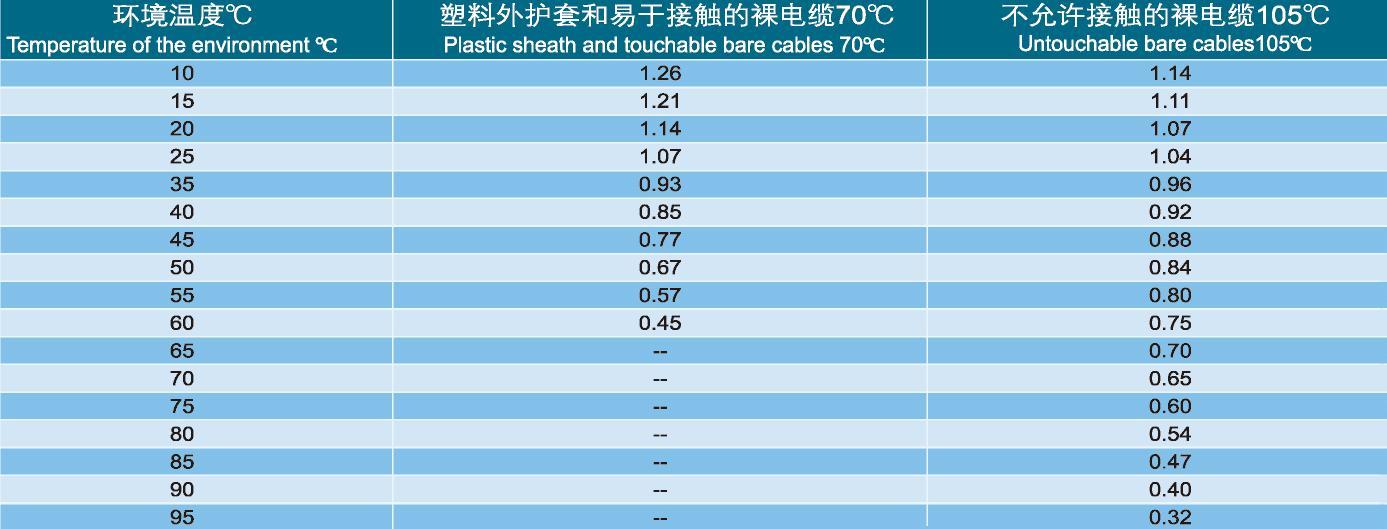

Table 5 Correction coefficient when ambient air temperature is not equal to 30℃

Table 6 List of laying methods (check the index of current carrying capacity of various laying methods)

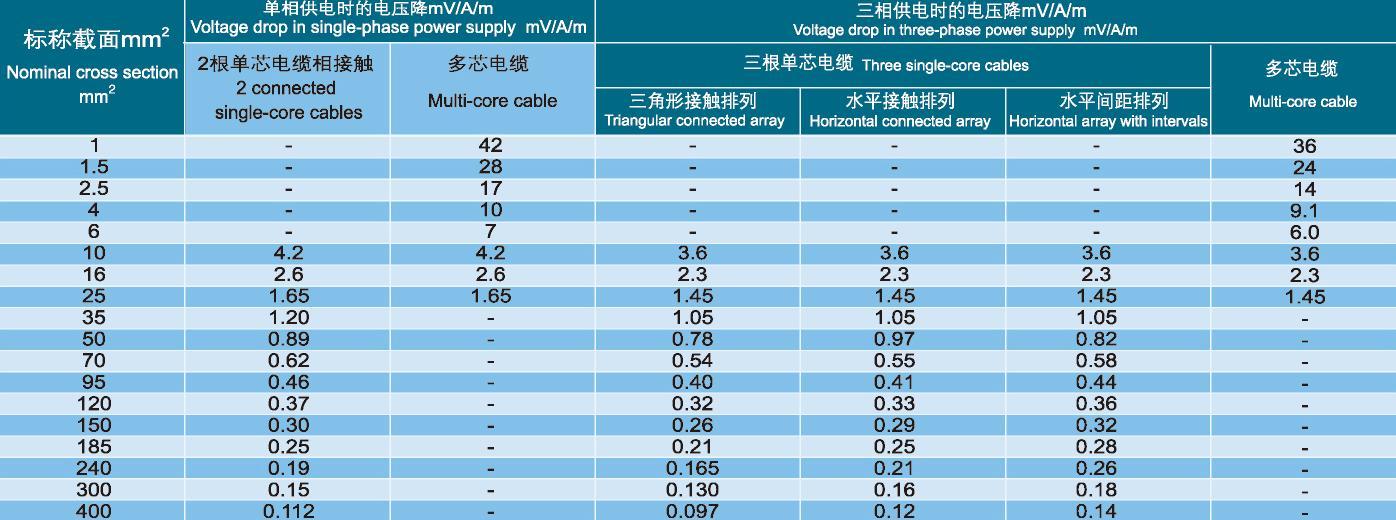

Table 7 Voltage drop

-

Cable accessories

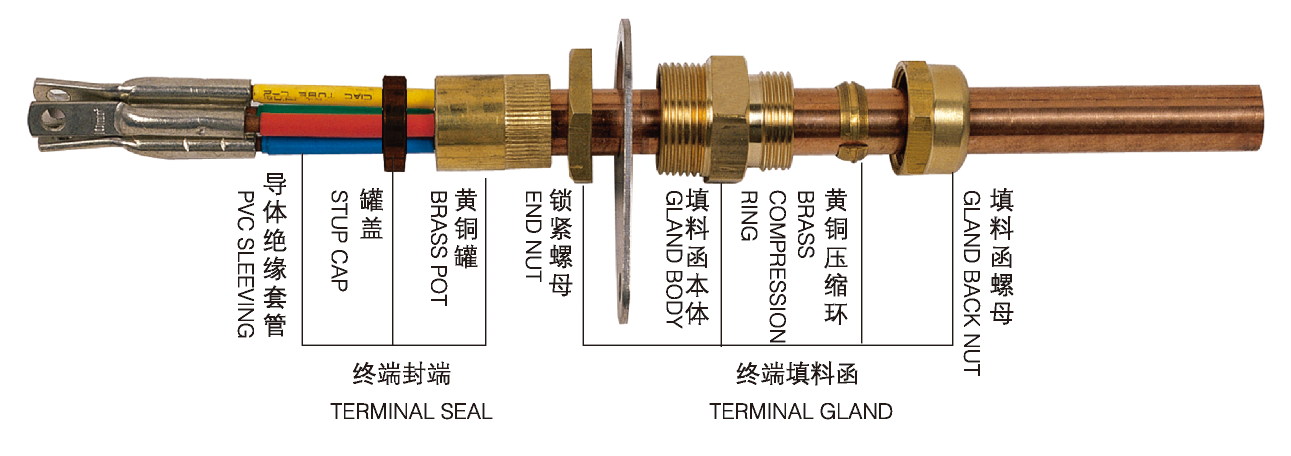

One. Terminal

A complete end installed at the end of a mineral insulated cable, usually including a capping and a stuffing box or a combined end/stuffing box. Each cable requires a terminal.

The representation method of the terminal: copper core copper sheathed mineral insulated cable terminal, rated voltage 750V, suitable for single core 4mm2 cable

is expressed as: ZA-750 1×4

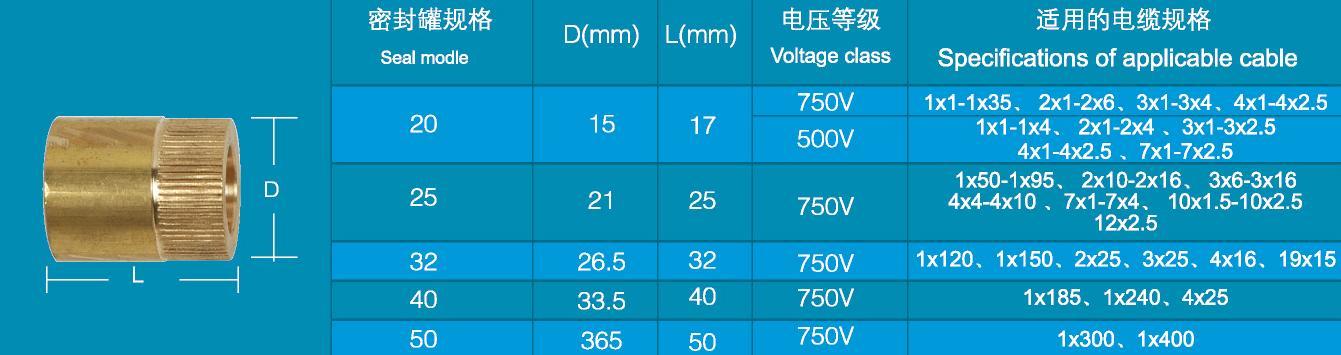

1. Terminal sealing: A part of the cable terminal used to seal the end of the cable to prevent moisture from entering. The sealing includes a brass sealing tank, a sealing tank cover, a terminal sealing material, and an insulating tube for the exposed part of the conductor. The single-core cable can be without a sealed tank and a sealed tank cover.

2. Terminal stuffing box: a part of the cable terminal, which is mainly used to connect cables and switch cabinets and branch boxes. It includes stuffing box body, compression ring, stuffing box nut, and lock nut.

Cable accessories include: terminals, wiring terminals, grounding lugs, intermediate connector accessories

Second. TerminalSub

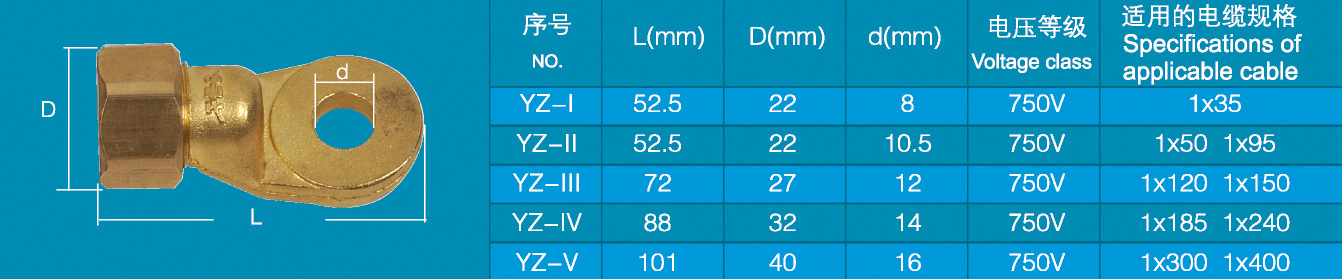

Used to connect the conductor and control cabinet terminal or power supply. It is composed of a press-fit nut, a press-fit oblique block, and a terminal body. There are two types of terminal blocks. One is the press-fit terminal, which is suitable for the connection of cables above 35mm2, and the other is the press-fit terminal, which is suitable for the connection of 6-25mm2 cables. Small size cables 4mm2 and below can be without terminal blocks.

; press-fit terminal blocks

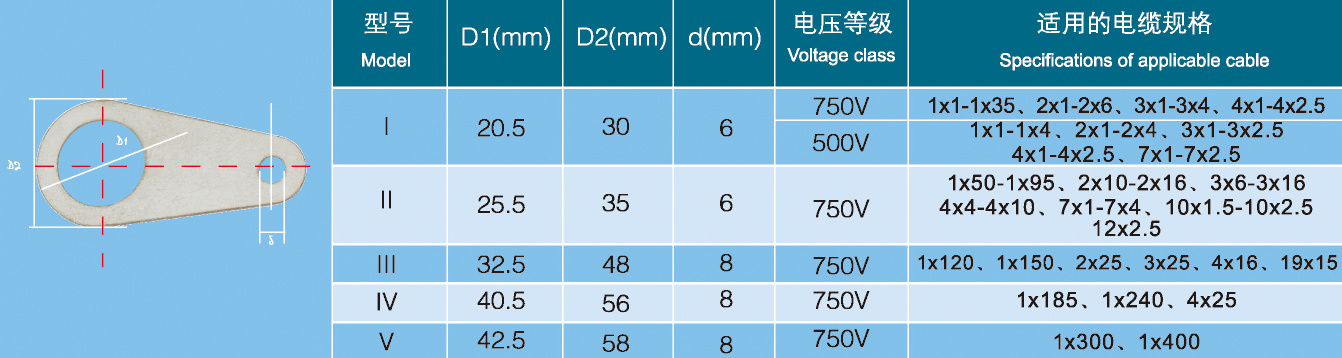

Three, grounding sheet

When the copper sheath of the cable is used for grounding or the grounding of other electrical equipment connected with the copper sheath of the cable, a grounding sheet is required

How to select cable accessories (without intermediate connector accessories)

Remarks: choose cable accessories according to actual needs.

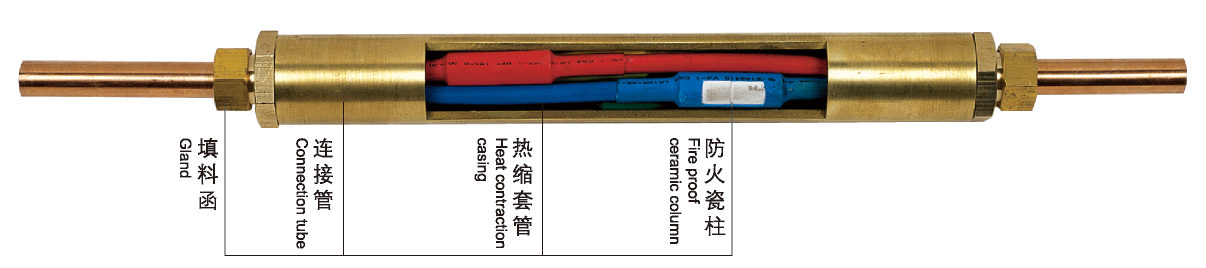

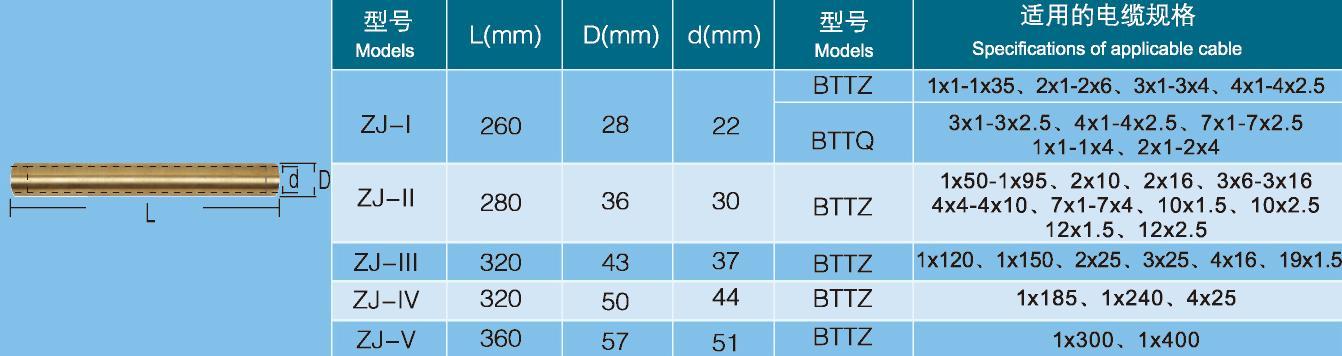

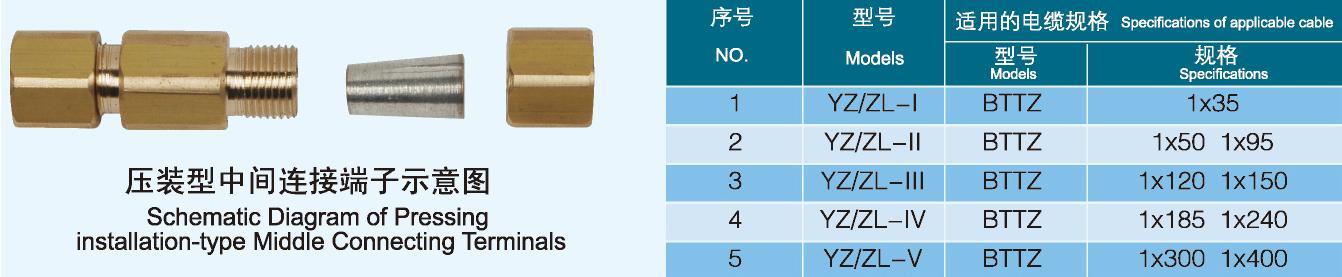

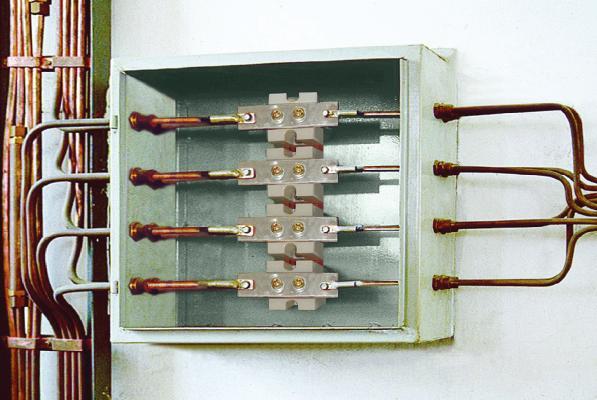

Four. Intermediate connector accessories

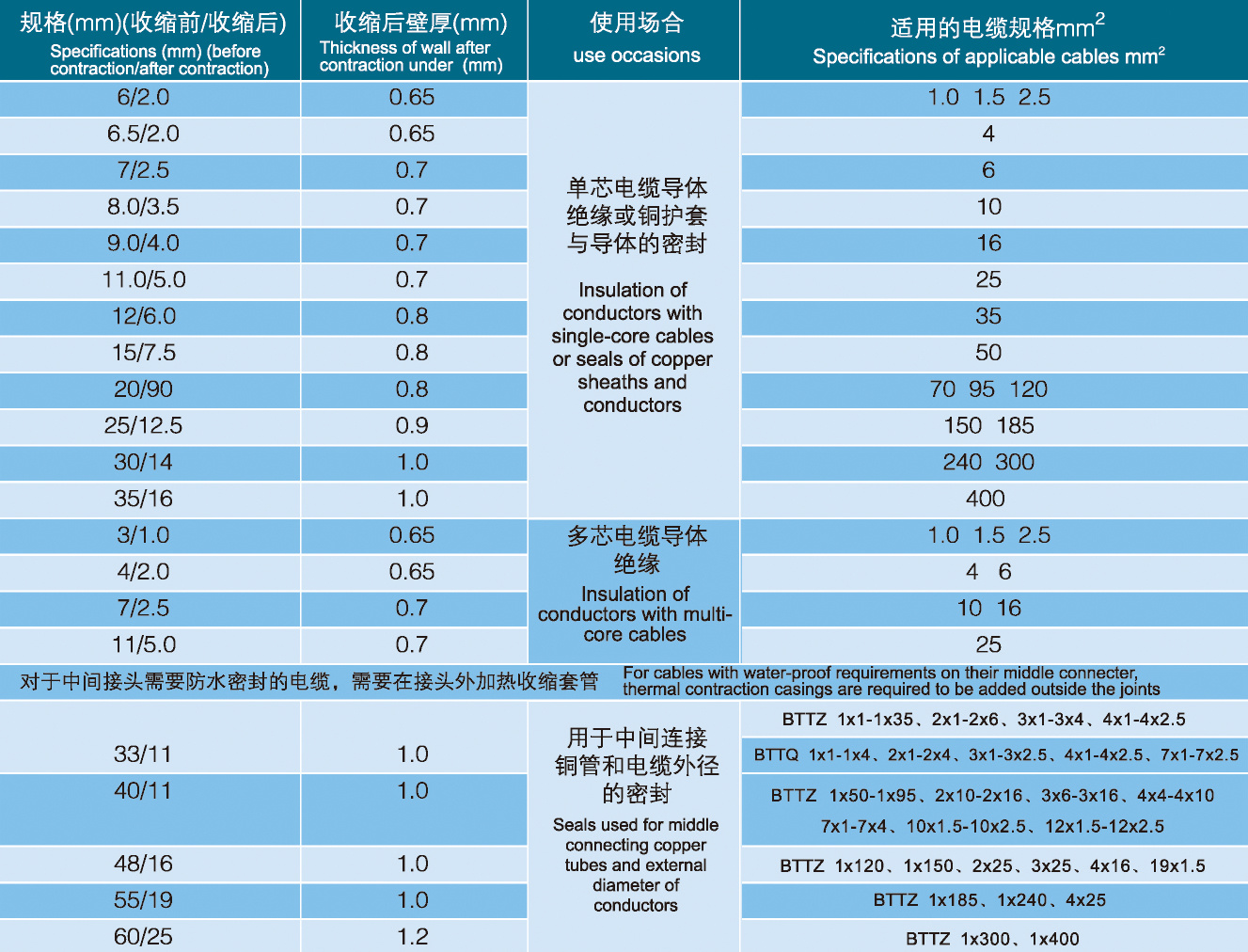

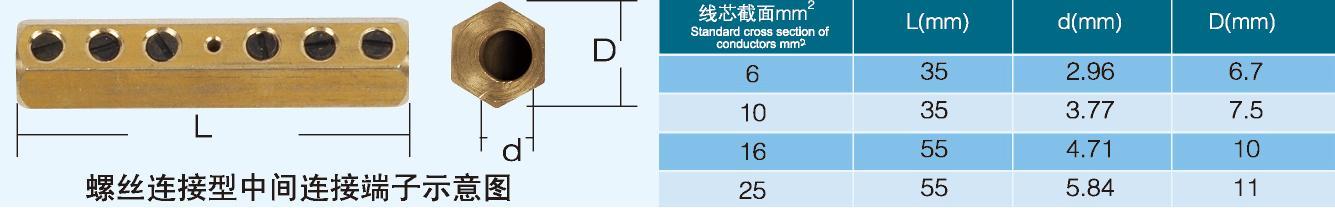

When the cable length is not long enough, it is necessary to use the intermediate connector accessory. It is a device that connects two cables of the same specification into one cable. Set of terminal sealing cans (not required for single-core cables), heat shrinkable tubing, intermediate connection terminals, and fireproof ceramic pillars. The middle junction stuffing box includes the stuffing box body, compression ring, and stuffing box nut, which are mainly used to connect the intermediate connecting pipe and the cable. The middle connecting terminal is used to connect two conductors of the same specification cable. It has three forms: one is crimp type, suitable for connecting cables of 4mm2 and below, the other is crimp type, suitable for connecting cables above 35 mm2, and third , Screw connection type, suitable for connecting 6-25mm2 cables.

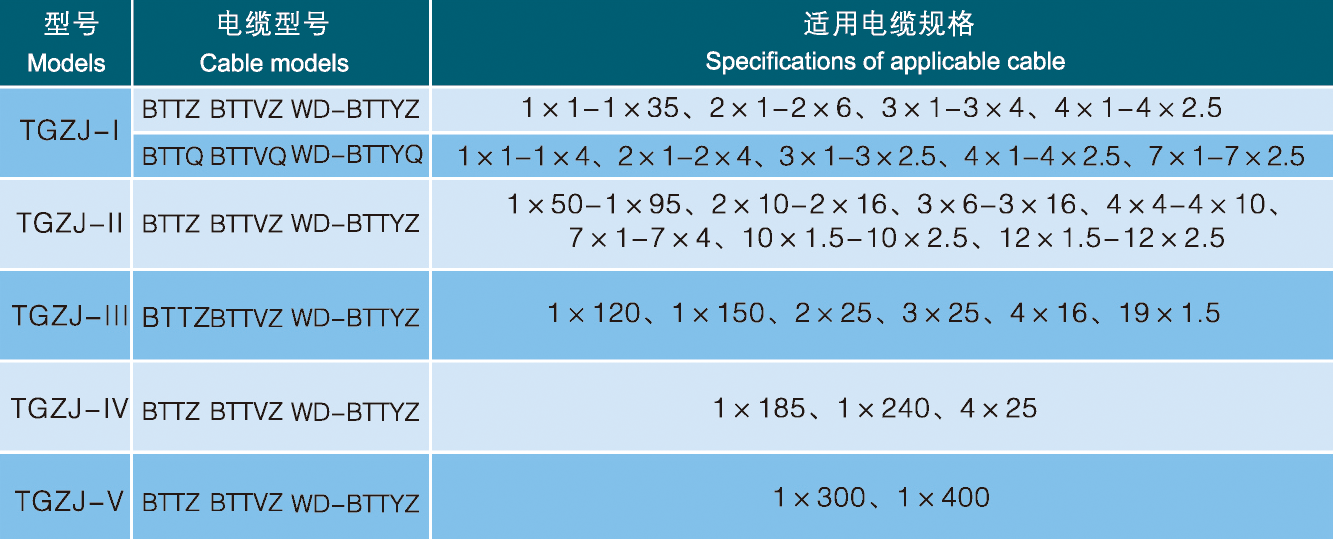

Intermediate connector accessory representation method: copper core copper sheathed mineral insulated cable middle connection, rated voltage 750V, suitable for single core 4mm2 cable connection.

is expressed as: TGZJ-I 750 1X4

Table 8 Intermediate connector accessories

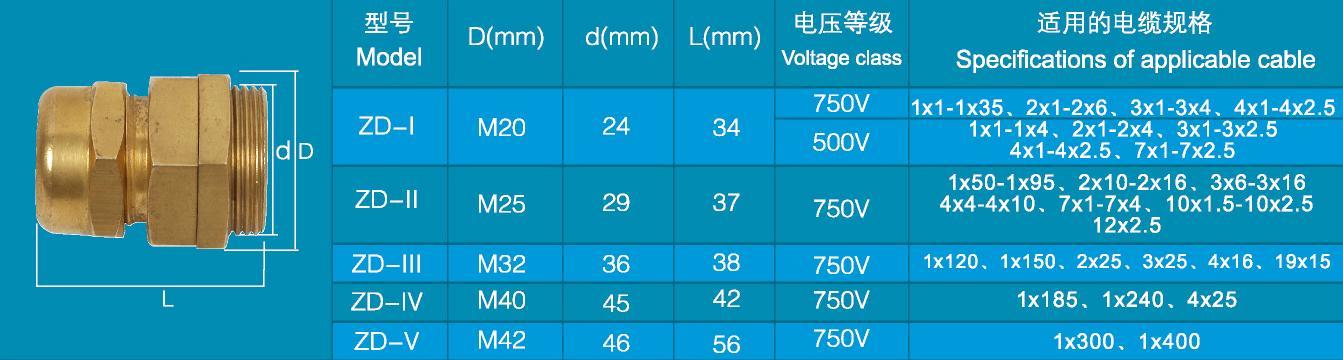

Table 9 Terminal stuffing box

Table 10 Terminal and intermediate connection sealed tank

Table 11 Press-fit terminal

Table 12 Crimp type terminal (copper nose)

Table 13 Grounding lug

Sealed insulation accessories

There are two types of sealing and insulating accessories: sealing material and insulating sleeve with exposed conductor. The sealing material is suitable for multi-core cables, and the insulating sleeve of the exposed part of the conductor is suitable for single-core cables.

1. Sealing material: The sealing mud is greasy, and the maximum use temperature is 250℃.

2. Insulating sleeves for exposed conductors: divided into plastic heat-shrinkable sleeves and porcelain sleeves. Plastic heat-shrinkable sleeves are divided into 70°C and 250°C. The 250°C plastic insulating sleeves are Adopt irradiated polyolefin material; Porcelain sleeve is made by pressing ceramic material, mainly used in high temperature and fireproof places.

Table 14 Specifications of heat shrinkable tubing

Table 15 Intermediate connection casing specifications

Intermediate connector accessories

Table 16 Intermediate Stuffing Box

Intermediate connection terminal

A. Press-fit type intermediate connection terminal: Composed of press-fit nut, press-fit oblique block and terminal body. It is mainly suitable for the connection of cable conductors of 35mm2 and above. (See Table 17).

Intermediate connection terminal

B. Crimping type intermediate connection terminal: (copper nose), there are standard parts on the market. Mainly suitable for the connection of cable conductors of 1.5-4mm2.

C. Screw connection type intermediate connection terminal: mainly suitable for 6-25mm2 cable conductor connection. (See Table 18)

Branch cable

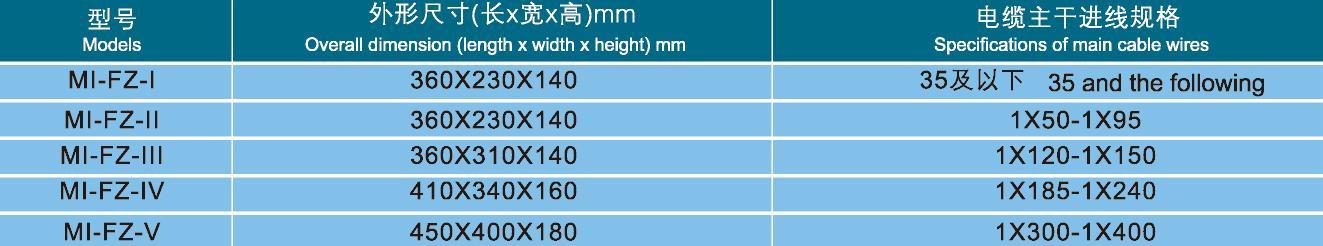

Mineral insulation can realize branching. By using T-connected and cross-connected branch junction boxes, the problem of branching of mineral insulated cables in any place and any occasion is solved, and the flame-retardant and fire-resistant branch of general fire-resistant plastic cables are also solved. characteristic. Selection of mineral insulated cable branch junction box: Users only need to provide the specifications of the main incoming line and branch line, and determine the specifications of the branch junction box according to the main incoming line. The structure of the branch junction box is designed by us.

Model specification of branch junction boxGrid

-

I. General requirements for the laying of mineral insulated cables

1. See Table 6 for the laying method of mineral insulated cables

2. Before laying the cable, check whether the cable is in good condition and whether the insulation resistance meets the standard requirements.

3. When the cable is laid, the spacing between the fixed points, except that the bracket is fixed at the bracket, can be fixed according to the recommended values in the following table. In the exposed area, if the cables of the same direction have large, medium and small specifications, they can be fixed according to the minimum specifications of the cable standard, or the distance between the files can be fixed in consideration of neatness and beauty. When the cable is laid obliquely, when the cable is 30° or less from the vertical, it is fixed at the vertical distance; when it is greater than 30°, it is fixed at the horizontal distance.

4. When laying the cable, The corners and both sides of the middle connector should be fixed if possible.

5. When calculating the required length for laying cables, a margin of 1% should be considered.

6. Appropriate protective measures should be taken for parts of the cable that may be mechanically damaged during operation.

7. When single-core cables are laid, they should be laid one by one. After each group is arranged and straightened, arrange and bind again. The spacing between bindings is preferably 1-1.5m.

8. When the cable is laid in an environment corrosive to the copper sheath, or when it is partially buried or laid through a pipe, a PVC outer sheath or a low-smoke and halogen-free outer sheath should be used .

9. During the wiring process, the end of the cable should be temporarily sealed immediately after it is sawed.10, the cable length is equal When the linear laying or connecting electrical appliances may vibrate, an expansion ring should be installed where permitted.

11. General mineral insulated cables do not need to be laid through pipes, special For occasions where pipes must be worn, see the table on the right (single-core cables are not allowed to be laid through metal pipes alone).

12. It can be buried in the ground, but it’s better not to have a middle If the joints cannot be avoided, the joints shall be waterproofed or cable wells shall be provided.

13. For large cross-section single-core cables, eddy current elimination measures should be taken when used in AC power grids. Under the action of alternating current, transverse eddy currents will be formed on the copper sheath, which will cause energy loss. When the line load is very heavy and more than two sets of cables are required, two or more sets of cables can be arranged in the form of Figure 1 ab, but there should be a distance of twice the outer diameter of the cable between each set, and each set of cables The wiring positions should be the same. In addition, when the cable enters the distribution box or cabinet, it is necessary to punch holes on the panel surface of the cabinet to fix the cable. Also, to prevent the cable from generating vortexes on the iron surface of the box or cabinet, press on the panel surface of the cabinet or cabinet. The way shown in Figure 2 is to open holes, or padded non-magnetic material partitions to fix the cables. This kind of bracket is generally made of aluminum busbar or copper busbar. The holes should be opened according to the above method to prevent eddy currents.

14. When laying single-core cables, it is recommended to follow Table 19 The cable arrangement method listed in the cable should be laid, and there should be a gap not less than 2 times the outer diameter of the cable between each cable. If there is no gap, the current-carrying capacity reduction factor should be considered.

-

Mineral insulated cables have been widely used in high-rise buildings, shopping malls, star hotels, hospitals, theaters, conference centers, libraries, museums, government agencies, financial centers, radio and television centers, sports centers, industrial and mining, airports, tunnels, Subway, light rail, underground garage, civil air defense, shipbuilding, petrochemical industry,

Offshore oil platforms, aerospace, iron and steel metallurgy, tobacco, military industry, etc.

1, high-rise building

general lighting, emergency lighting, fire alarm, fire-fighting electrical wiring, emergency elevator and lifting equipment wiring, computer room control wiring, main/sub-main power distribution system wiring, dual power control wiring.

2, airport terminal

General lighting and power supply, emergency lighting, fire monitoring system, fire alarm system, fire electrical wiring.

3, subway, light rail, tunnel

general lighting, emergency lighting, fire alarm, fire-fighting electrical wiring, ventilation wiring and life-saving system.

4, shopping centers, hotels, hospitals

general lighting, emergency lighting lines, emergency broadcasting lines, emergency elevators, fire fighting lines and lifting equipment lines.

5, conference center, sports center, theater

general lighting, emergency lighting lines, emergency broadcasting lines, emergency elevators and lifting equipment lines.

6, libraries, museums, data processing centers

general lighting, emergency lighting lines, fire alarm control lines, fire-fighting electrical lines.

7, parking lot, underground garage, air defense

general lighting, emergency lighting, fire alarm, fire fighting lines and ventilation lines.

8. Places of interest

general lighting, emergency lighting, fire alarm, fire-fighting electrical wiring.

9, petrochemical, petroleum platform

general lighting, emergency lighting lines, high-temperature places, fire-fighting lines, high-power lines, lines in potentially dangerous explosive areas.

10. Warships, ships

Power transmission line for generator room, fire monitoring system, fire alarm system, smoke emission and ventilation line, kitchen power line, large power line, dual power control line, emergency lighting, emergency broadcast line, computer room control line.

11. Iron and Steel Metallurgy

High temperature environment power and control lines, emergency power supply, large power lines, power supply lines that cannot be cut off, power transmission lines in the generator room.

12. Power plant

large power lines, general lighting, emergency lighting, fire alarm, fire-fighting electrical lines.

13. Power plants, nuclear power plants

General lighting, emergency lighting lines, computer room control lines, large power lines, high temperature environment power and control lines, lines in potentially dangerous explosive areas.

14、Aerospace

General lighting, emergency lighting lines, computer room control lines, large power lines, high temperature environment power and control lines, lines in potentially dangerous explosive areas.

15, oil depot, ammunition depot

general lighting, emergency lighting, fire alarm, smoke emission, flammable and explosive and ventilation lines.

16, industrial and mining

Smoke exhaust fan, high-frequency heating furnace, high-temperature places, fire-fighting lines, large power lines.

Previous

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!