Fire-resistant wire and cable

This product is suitable for all circuits that still need to maintain normal operation in the event of a fire, such as fire protection systems, emergency lighting systems, life-saving systems, alarms and important monitoring circuits in industrial and civil buildings. Commonly used: power supply lines and control lines for fire pumps, sprinkler pumps, fire elevators, fire shutter doors, electric fire doors, smoke exhaust system fans, smoke exhaust valves, fire dampers, power supply control lines, fire alarm systems, manual alarm lines, fire protection Broadcasting and telephone lines High-rise buildings and airports, subways and other important facilities such as security closed-circuit television lines, centralized power supply emergency lighting lines, control and protection of power lines, important relay protection lines and operating power lines in large and medium-sized substations The computer monitors the circuit.

Classification:

Key words:

Fire-resistant wire and cable

- Description

- Model and specification

- Usage characteristics

- Parameter

- Transportation

-

- Commodity name: Fire-resistant wire and cable

- Commodity ID: 1329827702323695616

This product is suitable for all circuits that still need to maintain normal operation in the event of a fire, such as fire protection systems, emergency lighting systems, life-saving systems, alarms and important monitoring circuits in industrial and civil buildings. Commonly used: power supply lines and control lines for fire pumps, sprinkler pumps, fire elevators, fire shutter doors, electric fire doors, smoke exhaust system fans, smoke exhaust valves, fire dampers, power supply control lines, fire alarm systems, manual alarm lines, fire protection Broadcasting and telephone lines High-rise buildings and airports, subways and other important facilities such as security closed-circuit television lines, centralized power supply emergency lighting lines, control and protection of power lines, important relay protection lines and operating power lines in large and medium-sized substations The computer monitors the circuit.

This product is suitable for all circuits that still need to maintain normal operation in the event of a fire, such as fire-fighting systems, emergency lighting systems, life-saving systems, alarms and important monitoring circuits in industrial and civil buildings. Commonly used: power supply lines and control lines for fire pumps, sprinkler pumps, and fire elevators

Power supply control lines for fire shutter doors, electric fire doors, smoke exhaust system fans, smoke exhaust valves, and fire dampers

The manual alarm line of the fire alarm system, fire broadcasting and telephone lines

Security CCTV lines in important facilities such as high-rise buildings, airports and subways

Emergency lighting circuit with centralized power supply, control and protection power circuitImportant relay protection circuit and operating power circuit for large and medium-sized substations

Computer monitoring circuit

Product executive standard: GB/T19666-2005, GB/T5023-2008, GB/T12706.1-2008, GB/T9330-2008

Description of fire-resistant wire and cable

Fire-resistant wire and cable refers to a cable that can maintain normal operating characteristics for a certain period of time under specified test conditions, according to the standard requirements of GB/T19216-2008 "Cable or Optical Cable Line Integrity Test under Flame Conditions" , Fire-resistant wires and cables must be burned at 750°C for 90 minutes, and the 2A fuse will not blow.

fire-resistant wire and cable use high-temperature resistant organic flame-proof tape as the fire-resistant layer. According to GB/T19666-2005, fire-resistant wires and cables can be divided into flame-retardant and fire-resistant wires and cables and non-flame-retardant and fire-resistant wires and cables. Flame-retardant and fire-resistant wires and cables mainly include flame retardants in the insulation or sheath, which can simultaneously meet the flame retardant characteristics. Non-flame-retardant fire-resistant wires and cables do not add flame-retardant in the insulation or sheath. It does not have flame-retardant properties.Flame retardant grade

Fire temperature

Fire time

The volume of non-metallic materials for laying cables in bundles

Charring height

Self-extinguishing time

Applicable products

A

≥815℃

40min

≥7L/m

≤2.5m

≤1h

Flame-retardant and fire-resistant cable

B

≥815℃

40min

≥3.5L/m

≤2.5m

≤1h

Flame-retardant and fire-resistant cable

C

≥815℃

20min

≥1.5L/m

≤2.5m

≤1h

Flame-retardant and fire-resistant cable

D

≥815℃

20min

≥0.5L/m

≤2.5m

≤1h

Flame-retardant and fire-resistant wire

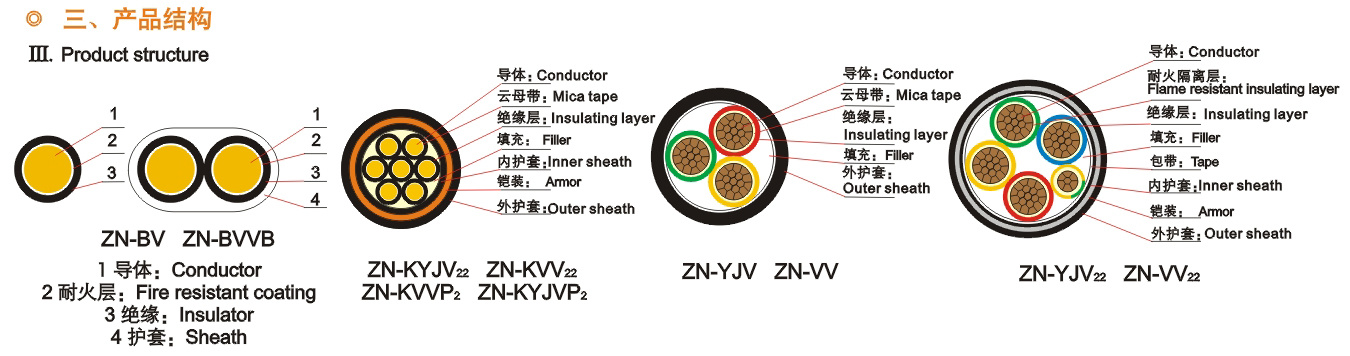

Product structure:

-

Model representation method of flame-retardant and fire-resistant wire and cable

The model representation method of the flame-retardant and fire-resistant wire and cable: The model of the flame-retardant and fire-resistant wire and cable is added ○-△-□ before the model of the ordinary cable. The combustion level is divided into four levels ABCD, □- is the code of fire-resistant wire and cable, which is represented by N. Flame retardant Class A fire resistance: ZAN Flame retardant Class B fire resistance: ZBN Flame retardant Class C fire resistance: ZCN

The product is expressed by model, rated voltage, core number, nominal cross section and the number of this standard.

For example: rated voltage 450/750V flame-retardant fire-resistant PVC wire, flame-retardant grade is C, single core, 4mm2, expressed as ZCN-BV 450/750V 1*4 Q/TEC16.02-2005 rated voltage 600/1000V resistance Flame-retardant and fire-resistant cross-linked polyethylene insulated and PVC sheathed power cable, flame retardant grade is Class B 3-core, 240mm2, is ZBN-YJV 00/1000V 3*240 Q/TEC16.02-2005 Flame retardant Representation of fire-resistant cable products

Cable model and nameModel

Name

Flame retardant rating

Core number

Cross section

mm²额定电压

Rated voltage

vZN-BV

PVC insulated flame retardant fire resistant wire with copper core

A、B、C、D

1

1.5-400

450/750

ZN-BVV

PVC insulated flame retardant fire resistant round cable with copper core and sheath

A、B、C、D

1-5

1.5-35

300/500

ZN -BVVB

PVC insulated flame retardant fire resistant flat cable with copper core and PVC sheath

A、B、C、D

2,3

0.75-10

300/500

ZN -BVR

PVC insulated flame retardant fire resistant flexible cable with copper core

A、B、C、D

1

2.5-70

450/750

ZN -RVS

PVC insulated flame retardant fire resistant stranded connecting flexible cable with copper core

A、B、C、D

1

0.75-2.5

300/300

ZN -RV

Sheathless flame retardant fire resistant flexible cable with copper core

A、B、C、D

1

1.5-240

450/750

ZN -KVV

PVC insulated flame retardant fire resistant control cable with PVC sheath

A、B、C、D

2-61

1-10

450/750

ZN -KVV22

PVC insulated flame retardant fire resistant control cable with PVC sheath and steel tape armoring

A、B、C、D

2-61

1-10

450/750

ZN -KVVP2

PVC insulated flame retardant fire resistant control cable with PVC sheath and copper tape shielding

A、B、C、D

2-61

1-10

450/750

ZN -KVVP2-22

PVC insulated flame retardant control cable with PVC sheath, copper tape shielding and steel tape armoring

A、B、C、D

2-61

1-10

450/750

ZN -KYJV

Crosslinked polyethylene insulated flame retardant fire resistant control cable with PVC sheath

A、B、C、D

2-61

1-10

450/750

ZN -KYJV22

Crosslinked polyethylene insulated flame retardant and fire resistant control cable with PVC sheath and steel tape armoring

A、B、C、D

2-61

1-10

450/750

ZN -KYJVP2

Crosslinked polyethylene insulated flame retardant fire resistant control cable with PVC sheath and copper tape shielding

A、B、C、D

2-61

1-10

450/750

ZN -KYJVP2-22

Crosslinked polyethylene insulated flame retardant fire resistant control cable with PVC sheath, steel tape armoring and copper tape shielding

A、B、C、D

2-61

1-10

450/750

ZN -VV

PVC insulated flame retardant fire resistant cable with PVC sheath

A、B、C、D

1-5

1.5-800

600/1000

ZN -VV22

PVC insulated flame retardant fire resistant cable with PVC sheath and steel tape armoring

A、B、C、D

1-5

1.5-400

600/1000

ZN -YJV

Crosslinked polyethylene insulated flame retardant fire resistant cable with PVC sheath

A、B、C、D

1-5

1.5-800

600/1000

ZN -YJV22

Crosslinked polyethylene insulated flame retardant fire resistant cable with PVC sheath and steel tape armoring

A、B、C、D

1-5

1.5-400

600/1000

-

Using Features

The rated voltage U0/U of the cable is 0.6/1KV. The rated voltage U0/U of the flame-retardant and fire-resistant control cable is 450/750V, and the rated voltage of the flame-retardant and fire-resistant wire and cable U0/U is 450. /750V and below.

The long-term allowable working temperature of PVC insulated cables does not exceed 70℃, and the long-term allowable working temperature of XLPE insulated cables does not exceed 90℃

The ambient temperature during installation should not be lower than 0°C.

The minimum bending radius when the cable is installed

The outer diameter (D) of the flame-retardant and fire-resistant wire is less than 25mm, the allowable bending radius of the cable should not be less than 4D, the outer diameter (D) is 25mm and above, and the allowable bending radius of the cable should not be less than 6D.

Flame-retardant and fire-resistant control cables: cables without armor layers should be no less than 6 times the outer diameter of the cables, cables with armored or copper tape shielding structures should be no less than 12 times the outer diameter of the cables.

The minimum bending radius of flame-retardant and fire-resistant power cables is shown in the tableProject

Single core cable

Multi-core cable

Unarmored

Armored

Unarmored

Armored

Minimum bending radius during installation

20D

15D

15D

12D

D-Outer diameter of cable

Table 4 Nominal cross-section of neutral conductor of multi-core cable

Nominal cross section of main insulated core conductor /min2

Nominal cross section of neutral conductor /min2

3+1, 3+2, 4+1 Cores

4, 5 Cores

4

2.5

4

6

4

6

10

6

10

16

10

16

25

16

25

35

16

35

50

25

50

70

35

70

95

50

95

120

70

120

150

70

150

185

95

185

240

120

240

300

150

300

400

185

400

Single-core cable conductive core is round, 16mm2 and above can be pressed tightly. For multi-core cables with a cross-section of 35mm2 and below, the core should be round, and those with a cross-section of 50mm2 and above should be fan-shaped, tile-shaped or semicircular. The fourth core (neutral core) in a four-core cable can be round or fan-shaped. The neutral wire of a five-core cable can be round or tile-shaped. Those with a diameter of 6mm2 and below are allowed to be composed of a single conductor, and those with a diameter of 10mm2 and above are composed of multiple single wires. The shaped conductor (sector, tile or semicircle) should be tightly pressed.

Table 5 Compact round core diameter

Cross Section mm2

Min.number of single wire

Overalll diameter mm

16

6

4.8

25

6

6

35

6

7

50

6

8.4

70

12

10

95

15

11.6

120

18

13

150

18

14.6

185

30

16.2

240

34

18.5

300

34

22.7

400

53

25.6

Power cable section range: see table 6

Number of cores

Section mm2

1

1.5-800

2

1.5-185

3

1.5-300

4

1.5-300

3+1

2.5-300

5

1.5-240

3+2

2.5-240

4+1

2.5-240

Single-core steel ribbon cable is only suitable for DC system.

Insulated core identification: flame-retardant and fire-resistant power cables are separated according to the requirements of plastic insulated power cable insulation cores, and flame-retardant and fire-resistant control cables are separated according to the identification requirements of plastic insulated control cables. Fire-resistant wires and cables are color-separated according to the identification requirements of plastic insulated wires and cables.

Main performance

The fire resistance of the finished wire and cable is that it burns for 90 minutes under a flame of 750℃ and does not break down under the rated voltage. The test device for its fire resistance characteristics should comply with GB/T19216.11-2003 and IEC60331-11:1999, and the test procedures and requirements for fire resistance characteristics should comply with GB/T19216.21-2003 and IEC60331-21:1999

The flame-retardant properties of the finished flame-retardant and fire-resistant wire should be able to withstand 5 cycles of vertical burning test without transmitting flame. After the test, the continuous burning time of the sample should not exceed 1h. The finished cable should be subjected to a bundled cable burning test. After the test, the height of the scorched or affected part of the cable should not exceed 2.5m above the point of action of the flame.

Wire and cable should withstand -15℃ low temperature winding test or low temperature impact test. After the test, there should be no visible cracks on the surface of the sample.

70℃ finished wire insulation volume resistivity should be greater than 1*1010Ω•cm.

The finished flame-retardant and fire-resistant wire should be able to withstand the 2.5KV AC voltage test without breakdown in 5 minutes. The finished flame-retardant and fire-resistant control cable should be able to withstand the 3KV AC voltage test without breakdown in 5 minutes. The finished flame-retardant and fire-resistant power cable should be able to withstand the 3.5KV AC voltage test without breakdown within 5 minutes

Flame-retardant and fire-resistant wires and cables are made of highly flame-retardant polyvinyl chloride plastic, with an oxygen index greater than 30%

Except for the above characteristics, other performances are the same as those of the same kind of ordinary cables.Key points for selecting fire-resistant cables

In the event of a fire, the wire core resistance increases due to the dramatic increase in ambient temperature. When the flame temperature is 800-1000℃, the conductor resistance increases by about 3-4 times. At this time, the system should still be guaranteed to work normally , Must check the voltage loss under this condition . Generally, it is enough to enlarge the selected wire and cable cross section under normal conditions (ie voltage deviation allowable value +5%~-5%) by one to two levels. Originally, when 50mm2 and below were selected, the first-level cross-section was enlarged, and when it was more than 70mm2, the second-level cross-section was enlarged.

The difference between high temperature resistant cables and fire resistant cables should be distinguished

Generally organic fire-resistant cables are not flame-retardant. If both fire-resistant and flame-retardant requirements are required, flame-retardant and fire-resistant cables or mineral insulated cables should be used.

Ordinary cables and fire-resistant cables are laid in the fire-resistant cable trough box, which may not meet the fire-resistant requirements. -

Specifications and reference data of fire-resistant wires and cables for electrical equipment7-Table 15

Table7 ZN-BV 450/750V copper core PVC Comprehensive data of insulated flame-retardant and fire-resistant wires and cables

Nominal section

Type of conductor

Refractory layermm

Insulation label

call thickness mmInsulation label

said outer diameter mm20℃Maximum conductor time

DC resistance70℃Minimum time

Insulation resistance MΩ•KmTheoretical weight kg/km

Layer*thickness

1.5

1

2*0.14

0.7

3.4

12.1

0.011

25.9

1.5

2

2*0.14

0.7

3.6

12.1

0.010

27.0

2.5

1

2*0.14

0.8

4.0

7.41

0.010

38.9

2.5

2

2*0.14

0.8

4.3

7.41

0.009

40.7

4

1

2*0.14

0.8

4.5

4.61

0.0085

55.0

4

2

2*0.14

0.8

4.8

4.61

0.0077

57.1

6

1

2*0.14

0.8

5.0

3.08

0.0070

75.7

6

2

2*0.14

0.8

5.4

3.08

0.0065

78.4

10

2

2*0.14

1.0

6.7

1.83

0.0070

126.2

16

2

2*0.14

1.0

7.8

1.15

0.0050

187.8

25

2

2*0.14

1.2

9.5

0.727

0.0050

286.4

35

2

2*0.14

1.2

10.6

0.524

0.0040

385.2

50

2

2*0.14

1.4

12.3

0.387

0.0045

542.6

70

2

2*0.14

1.4

14.1

0.268

0.0035

738.1

95

2

2*0.14

1.6

16.4

0.193

0.0035

995.9

120

2

2*0.14

1.6

18.1

0.153

0.0032

1236.2

150

2

2*0.14

1.8

20.0

0.124

0.0032

1540.8

185

2

2*0.14

2.0

22.3

0.0991

0.0032

1898.0

240

2

2*0.14

2.2

25.3

0.0754

0.0032

2448.2

300

2

2*0.14

2.4

28.1

0.0601

0.0030

3046.6

400

2

2*0.14

2.6

31.9

0.0470

0.0028

4022.9

Table 8 Comprehensive data of ZN-BVVB 300/500V copper core PVC insulated PVC sheathed flat flame-retardant fire-resistant cable

Number of cores*nominal cross section mm²

Minimum number of single wires in solid core or stranded conductor

Fire barrier

Layer*thickness mmInsulation thickness rating mm

Sheath thickness specified value mm

Dimensions mm

Minimum insulation resistance MΩ.km at 70℃

Maximum DC resistance at 20℃Ω/km

Theoretical weight kg/km

2*1.0

1

2*0.14

0.6

0.9

8.9*5.5

0.011

18.1

67.78

2*1.5

1

2*0.14

0.7

0.9

9.9*6.0

0.011

12.1

86.96

2*2.5

1

2*0.14

0.8

1.0

11.5*6.9

0.010

7.41

123.69

2*4

1

2*0.14

0.8

1.0

12.6*7.5

0.0085

4.61

161.31

2*4

7

2*0.14

0.8

1.0

13.3*7.8

0.008

4.61

169.11

2*6

1

2*0.14

0.8

1.1

14.0*8.3

0.0070

3.08

214.36

2*6

7

2*0.14

0.8

1.1

14.9*8.69

0.0065

3.08

224.39

2*10

7

2*0.14

1.0

1.2

18.2*10.5

0.0065

1.83

345.56

3*1.0

1

2*0.14

0.6

0.9

12.3*5.5

0.011

18.1

98.57

3*1.5

1

2*0.14

0.7

0.9

13.4*6.0

0.011

12.1

127.47

3*2.5

1

2*0.14

0.8

1.0

15.7*6.9

0.010

7.41

181.97

3*4

1

2*0.14

0.8

1.1

17.8*7.7

0.0085

4.61

245.17

3*4

7

2*0.14

0.8

1.1

18.5*7.8

0.008

4.61

250.58

3*6

1

2*0.14

0.8

1.1

19.5*8.3

0.0070

3.08

317.60

3*6

7

2*0.14

0.8

1.1

20.6*8.7

0.0065

3.08

332.93

3*10

7

2*0.14

1.0

1.2

24.3*10.5

0.0065

1.83

514.93

Table 9 Comprehensive data of ZN-BVV 300/500V copper core PVC insulated sheathed round flame-retardant fire-resistant cable

Number of cores*nominal cross section mm2

Type of conductor

Fire barrier

Layer*thickness mmSpecified value of insulation thickness mm

Specified value of sheath thickness mm

Theoretical outer diameter mm

Minimum insulation resistance MΩ.km at 70℃

20℃Maximum DC resistanceΩ/km

Theoretical weight kg/km

1.5

1

2*0.14

0.7

0.8

5.02

0.011

12.1

41.17

1.5

7

2*0.14

0.7

0.8

5.20

0.010

12.1

42.92

2.5

1

2*0.14

0.8

0.8

5.62

0.010

7.41

59.29

2.5

7

2*0.14

0.8

0.8

5.88

0.009

7.41

62.12

4

1

2*0.14

0.8

0.9

6.29

0.0085

4.61

77.34

4

7

2*0.14

0.8

0.9

6.59

0.0077

4.61

80.70

6

1

2*0.14

0.8

0.9

6.80

0.0070

3.08

100.23

6

7

2*0.14

0.8

0.9

7.16

0.0065

3.08

104.38

10

1

2*0.14

1.0

0.9

8.49

0.0065

1.83

166.84

2*1.5

1

2*0.14

0.7

1.2

10.84

0.011

12.1

145.23

2*1.5

2

2*0.14

0.7

1.2

11.20

0.010

12.1

151.21

2*2.5

1

2*0.14

0.8

1.2

12.04

0.010

7.41

183.89

2*2.5

2

2*0.14

0.8

1.2

12.56

0.009

7.41

192.84

2*4

1

2*0.14

0.8

1.2

12.98

0.0085

4.61

225.93

2*4

2

2*0.14

0.8

1.2

13.58

0.0077

4.61

236.47

2*6

1

2*0.14

0.8

1.2

14.00

0.0070

3.08

278.18

2*6

2

2*0.14

0.8

1.2

14.72

0.0065

3.08

291.04

2*10

2

2*0.14

1.0

1.4

17.78

0.0065

1.83

433.45

2*16

2

2*0.14

1.0

1.4

19.88

0.0052

1.15

579.90

2*25

2

2*0.14

1.2

1.4

23.32

0.0050

0.727

818.22

2*35

2

2*0.14

1.2

1.6

26.40

0.0044

0.524

1097.05

3*1.5

1

2*0.14

0.7

1.2

11.37

0.011

12.1

176.74

3*1.5

2

2*0.14

0.7

1.2

11.75

0.010

12.1

184.09

3*2.5

1

2*0.14

0.8

1.2

12.66

0.010

7.41

229.36

3*2.5

2

2*0.14

0.8

1.2

13.22

0.009

7.41

240.47

3*4

1

2*0.14

0.8

1.2

13.67

0.0085

4.61

288.23

3*4

2

2*0.14

0.8

1.2

14.32

0.0077

4.61

301.35

3*6

1

2*0.14

0.8

1.4

15.17

0.0070

3.08

377.85

3*6

2

2*0.14

0.8

1.4

15.95

0.0065

3.08

394.74

3*10

2

2*0.14

1.0

1.4

18.81

0.0065

1.83

571.65

3*16

2

2*0.14

1.0

1.4

21.07

0.0052

1.15

781.02

3*25

2

2*0.14

1.2

1.4

24.78

0.0050

0.727

1121.59

3*35

2

2*0.14

1.2

1.6

28.03

0.0044

0.524

1504.63

4*1.5

1

2*0.14

0.7

1.2

12.26

0.011

12.1

212.07

4*1.5

2

2*0.14

0.7

1.2

12.69

0.010

12.1

221.01

4*2.5

1

2*0.14

0.8

1.2

13.70

0.010

7.41

279.32

4*2.5

2

2*0.14

0.8

1.2

14.33

0.009

7.41

292.88

4*4

1

2*0.14

0.8

1.4

15.24

0.0085

4.61

371.43

4*4

2

2*0.14

0.8

1.4

15.96

0.0077

4.61

388.24

4*6

1

2*0.14

0.8

1.4

16.47

0.0070

3.08

468.68

4*6

2

2*0.14

0.8

1.4

17.34

0.0065

3.08

489.28

4*10

2

2*0.14

1.0

1.4

20.55

0.0065

1.83

718.09

4*16

2

2*0.14

1.0

1.4

23.08

0.0052

1.15

991.66

4*25

2

2*0.14

1.2

1.6

28.04

0.0050

0.727

1494.98

4*35

2

2*0.14

1.2

1.6

30.79

0.0044

0.524

1927.63

5*1.5

1

2*0.14

0.7

1.2

13.23

0.011

12.1

248.34

5*1.5

2

2*0.14

0.7

1.2

13.72

0.010

12.1

258.91

5*2.5

1

2*0.14

0.8

1.2

14.85

0.010

7.41

330.40

5*2.5

2

2*0.14

0.8

1.2

15.56

0.009

7.41

346.47

5*4

1

2*0.14

0.8

1.4

16.52

0.0085

4.61

441.34

5*4

2

2*0.14

0.8

1.4

17.33

0.0077

4.61

461.24

5*6

1

2*0.14

0.8

1.4

17.90

0.0070

3.08

561.02

5*6

2

2*0.14

0.8

1.4

18.87

0.0065

3.08

585.44

5*10

2

2*0.14

1.0

1.4

22.46

0.0065

1.83

866.56

5*16

2

2*0.14

1.0

1.6

25.70

0.0052

1.15

1231.57

5*25

2

2*0.14

1.2

1.6

30.74

0.0050

0.727

1818.57

5*35

2

2*0.14

1.2

1.6

34.22

0.0044

0.524

2390.33

Table 10 ZN-BVR 450/750V copper core PVC insulated flame-retardant fire-resistant flexible cable

Nominal cross-section of conductor mm2

Minimum number of single wires in stranded conductor

Fire barrier

Layer*thickness mmSpecified value of insulation thickness mm

Average outer diameter mm

Minimum insulation resistance MΩ.km at 70℃

20℃Maximum DC resistanceΩ/km

Theoretical weight kg/km

2.5

19

2*0.14

0.8

4.29

0.011

7.41

40.95

4

19

2*0.14

0.8

4.84

0.009

4.61

57.74

6

19

2*0.14

0.8

5.44

0.0084

3.08

79.36

10

49

2*0.14

1.0

7.32

0.0072

1.83

131.42

16

49

2*0.14

1.0

8.4

0.0062

1.15

193.20

25

98

2*0.14

1.2

10.14

0.0058

0.727

294.01

35

133

2*0.14

1.2

11.74

0.0052

0.524

397.22

50

133

2*0.14

1.4

13.64

0.0051

0.387

558.61

70

189

2*0.14

1.4

15.99

0.0045

0.268

760.76

Table 11 ZN --KVV 450/750V PVC insulated PVC sheathed flame-retardant fire-resistant control cable

Number of cores * section

structure

Outer diameter mm Theoretical weight kg/km

Number of cores * section

structure Outer diameter mm Theoretical weight kg/km

Number of cores * section

structure

Outer diameter mm

Theoretical weight kg/km 2*1.5

1/1.38

10.04

165.03

7*1.5

1/1.38

13.46

284.29

14*1.5

1/1.38

18.90

541.96

2*1.5

7/0.52

10.40

186.23

7*1.5

7/0.52

14.00

296.64

14*1.5

7/0.52

19.69

565.69

2*2.5

1/1.78

10.84

209.77

7*2.5

1/1.78

15.26

397.23

14*2.5

1/1.78

20.66

714.95

2*2.5

7/0.68

11.36

217.35

7*2.5

7/0.68

16.04

421.63

14*2.5

7/0.68

21.81

749.64

2*4

1/2.25

11.78

249.33

7*4.0

1/2.25

16.67

522.75

14*4.0

1/2.25

23.14

984.58

2*4

7/0.85

12.38

258.27

7*4.0

7/0.85

17.57

545.80

14*4.0

7/0.85

24.46

1027.51

2*6

1/2.76

12.80

298.87

7*6.0

1/2.76

18.20

682.12

14*6.0

1/2.76

25.39

1297.92

2*6

7/1.04

13.52

309.81

7*6.0

7/1.04

19.28

710.55

14*6.0

7/1.04

26.98

1332.19

3*1.5

1/1.38

10.57

196.00

8*1.5

1/1.38

15.09

354.89

16*1.5

1/1.38

19.87

604.95

3*1.5

7/0.52

10.95

202.57

8*1.5

7/0.52

15.68

369.82

16*1.5

7/0.52

20.72

631.46

3*2.5

1/1.78

11.43

248.36

8*2.5

1/1.78

16.41

456.80

16*2.5

1/1.78

22.15

826.10

3*2.5

7/0.68

11.99

257.94

8*2.5

7/0.68

17.26

478.61

16*2.5

7/0.68

23.38

866.25

3*4

1/2.25

12.44

304.45

8*4.0

1/2.25

17.96

603.65

19*1.5

1/1.38

20.90

695.09

3*4

7/0.85

13.09

315.80

8*4.0

7/0.85

18.95

629.63

19*1.5

7/0.52

21.80

725.54

3*6.0

1/2.76

14.14

411.71

8*6.0

1/2.76

20.04

807.57

19*2.5

1/1.78

23.30

952.07

3*6.0

7/1.04

14.91

426.97

8*6.0

7/1.04

21.23

843.95

19*2.5

7/0.68

24.60

998.09

4*1.5

1/1.38

11.46

236.92

10*1.5

1/1.38

17.48

442.30

24*1.5

1/1.38

24.72

889.85

4*1.5

7/0.52

11.89

248.51

10*1.5

7/0.52

18.20

460.75

24*1.5

7/0.52

25.80

928.98

4*2.5

1/1.78

12.42

292.75

10*2.5

1/1.78

19.08

569.20

24*2.5

1/1.78

27.12

1182.95

4*2.5

7/0.68

13.05

304.54

10*2.5

7/0.68

20.12

596.14

24*2.5

7/0.68

28.68

1240.19

4*4.0

1/2.25

14.16

409.27

10*4.

1/2.25

21.36

779.10

27*1.5

1/1.38

25.25

975.68

4*4.0

7/0.85

14.88

424.51

10*4.0

7/0.85

22.56

812.55

27*1.5

7/0.52

26.35

1018.52

4*6.0

1/2.76

15.39

503.85

10*6.0

1/2.76

23.40

1007.65

27*2.5

1/1.78

27.71

1302.80

4*6.0

7/1.04

16.26

522.57

10*6.0

7/1.04

24.84

1054.88

27*2.5

7/0.68

29.31

1365.49

5*1.5

1/1.38

12.43

285.57

12*1.5

1/1.38

18.01

479.85

30*1.5

1/1.38

26.14

1065.48

5*1.5

7/0.52

12.92

295.21

12*1.5

7/0.52

18.75

500.84

30*1.5

7/0.52

27.29

1112.24

5*2.5

1/1.78

14.11

373.35

12*2.5

1/1.78

19.67

629.58

30*2.5

1/1.78

28.70

1427.10

5*2.5

7/0.68

14.82

412.62

12*2.5

7/0.68

20.75

660.27

30*2.5

7/0.68

30.37

1495.54

5*4.0

1/2.25

15.38

489.59

12*4.0

1/2.25

22.02

864.85

37*1.5

1/1.38

28.14

1274.25

5*4.0

7/0.85

16.19

507.70

12*4.0

7/0.85

23.27

902.87

37*1.5

7/0.52

29.40

1330.12

5*6.0

1/2.76

16.76

606.22

12*6.0

1/2.76

24.14

1135.49

37*2.5

1/1.78

30.94

1716.24

5*6.0

7/1.04

17.73

628.50

12*6.0

7/1.04

25.63

1182.41

-

Delivery length

ZN-BV, ZN-BVV, ZN-BVR and other types of cables (wires) have a loop length of 100 meters, and the coil length should not be less than 100 meters. Short cables with a length of not less than 20 meters are allowed to be delivered, and the quantity should not be less than More than 10% of the total delivery length.

The delivery length of ZN-VV, ZN-VV22, ZN-YJV, ZN-YJV22 cables should not be less than 100m, and the measurement error should not be greater than 0.5%. It is allowed to deliver short cables with a length of not less than 20 meters. The quantity should not exceed 10% of the total delivery length.

The delivery length of fire-resistant control cables such as ZN-KVV, ZN-KVV22, ZN-KVVP2, ZN-KYJV, ZN-KYJV22, ZN-KYJVP2 should not be less than 100m, and the measurement error should not be greater than 0.5%. Allowable length Delivery of short-segment cables less than 20 meters should not exceed 10% of the total length of delivery. 4. According to the agreement between the two parties, delivery of cables of any length is allowed.Packaging signs and transportation

The cable should be properly packaged on a cable reel for delivery. The length of the cable extension should not be less than 300mm, and the end should be reliably sealed with a cable jacket.

A product quality certificate should be attached to each cable package. The certificate should be placed in an impermeable bag and fixed on the side of the cable reel.

The outside of each cable reel should be marked:

Length m Manufacturing Date: Year Month

standard number

Gross weight kg:

A symbol indicating the correct direction of rotation of the cable reel

Transportation and storage

Spools are not allowed to lay flat

During transportation, it is strictly forbidden to drop the cable reel with cables from a height, and it is strictly forbidden to damage the cables mechanically.

When hoisting packages, it is strictly forbidden to hoist several trays at the same time. On vehicles, ships and other transportation tools, the cable reel must be placed firmly and fixed with a suitable method to prevent mutual collision or overturning.

Next

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!