Liquid gas explosion-proof electric heater

Gas explosion-proof electric heater (hereinafter referred to as gas electric heater) is an electric heating device specially used to heat flammable and explosive gases such as natural gas and petroleum gas in a forced flow state. It can effectively solve the problem of liquid It is a technical problem that requires a large amount of heat to be supplemented when it is converted into a gaseous state or when a high pressure is reduced to a low pressure.

Classification:

Key words:

Liquid gas explosion-proof electric heater

- Description

- Specification

- parameter

- output power

- Application

-

- Commodity name: Liquid gas explosion-proof electric heater

- Commodity ID: 1329827726587744256

Gas explosion-proof electric heater (hereinafter referred to as gas electric heater) is an electric heating device specially used to heat flammable and explosive gases such as natural gas and petroleum gas in a forced flow state. It can effectively solve the problem of liquid It is a technical problem that requires a large amount of heat to be supplemented when it is converted into a gaseous state or when a high pressure is reduced to a low pressure.

gas explosion-proof electric heater (hereinafter referred to as gas electric heater) is an electric heating device specially used to heat natural gas, petroleum gas and other flammable and explosive gases in a forced flow state, which can effectively solve the problem of natural gas, petroleum gas, etc. It is a technical problem that requires a large amount of heat to be supplemented when the medium is converted from a liquid state to a gas state or a high pressure is reduced to a low pressure.

The gas electric heater is usually high pressure (even 20 MPa), and the user requires the heat exchange method of cold-packed heat and hot-packed cold. According to the temperature and anti-corrosion requirements, the shell of the gas electric heater can be made of stainless steel.

gas electric heaters are widely used in petroleum, natural gas fields, refineries, chemical plants, pharmaceutical plants, city gas and other corporate sectors. To ensure the safe, reliable and effective operation of the gas medium process.

-

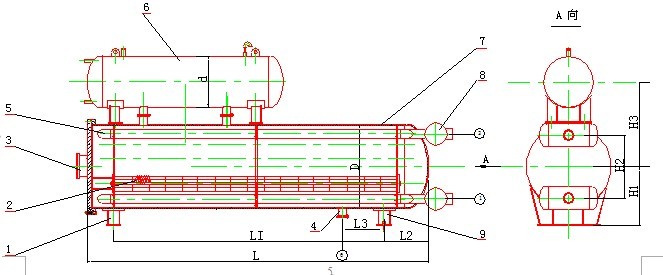

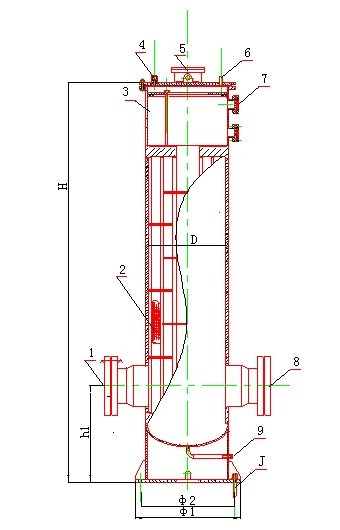

Structure size drawing of gas explosion-proof electric heater

Table 1 Technical parameters and dimensions of QJRQ vertical gas electric heater

Model

Rated power Kw

Rated voltage

V

Rated current (A)

Outline dimension (mm)

Body weight (Kg)

H

h1

D

Φ1

Φ2

J

6.3

MPa

4.0

MPa

2.5

MPa

QJRQ-24/3/380

24

380

36.5

2878

630

377

560

480

4-Φ26

832

760

732

QJRQ-36/3/380

36

380

54.7

3728

630

377

560

480

4-Φ26

1100

1000

995

QJRQ-60/3/380

60

380

91

3815

835

550

800

700

4-Φ38

2660

2300

1980

QJRQ-80/3/380

81

380

122

4415

835

550

800

700

4-Φ38

3130

2690

2330

QJRQ-100/3/380

100

380

152

3965

905

700

950

850

4-Φ38

4000

3400

2900

QJRQ-150/3/380

150

380

228

4570

905

700

950

850

4-Φ38

4450

3460

3170

QJRQ-200/3/380

200

380

304

5370

905

700

950

850

4-Φ38

5600

4800

4100

QJRQ-300/3/380

300

380

456

5616

1076

1000

1300

1200

4-Φ38

11400

9400

8480

QJRQ-400/3/380

400

380

608

6446

1106

1000

1300

1200

4-Φ38

13440

11400

9980

Note: The import and export calibers are the same, and the conventional production specifications for pipe diameters are

Import and export pipes are arranged on and under the body φ25~φ100.

The inlet and outlet pipes are on the two horizontal sides of the body φ200~φ300. (Pictured above)

1-left support, 2-MI heating cable, 3-electric junction box, 4-oil outlet, 5-gas flow channel, 6-heat conduction oil expansion tank

7-heater housing, 8-inlet and outlet pipe port, 9-right support

-

Technical parameters

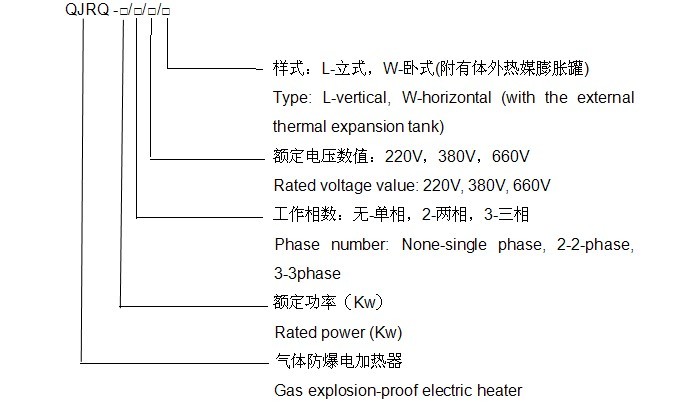

Model meaning

Main technical data

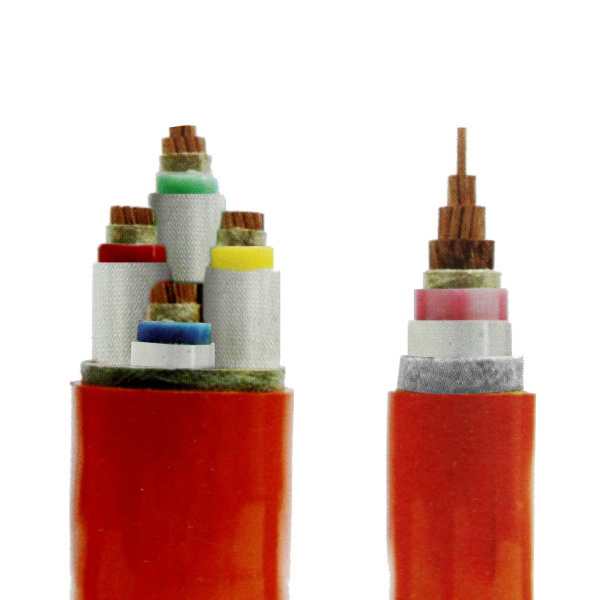

1 intake pipe 2MI heating cable 3 expansion tank 4 oil filling port 5 electrical junction box

6 explosion-proof breathing port 7 oil level indicator window 8 air outlet pipe 9 sewage pipe

-

Technical performance and characteristics

1. The gas electric heater uses mineral insulated (MI) heating cables as heating elements, and transfers heat to the heat exchange cavity through a heat medium. The heated medium and the heating element are indirectly transferred.

2. The heated gas flows along the baffle guide in the heat exchange cavity, which has a good process heat exchange effect.

3. There is a temperature sensor at the outlet of the heat exchange chamber, which can realize automatic temperature monitoring after connecting with the matching temperature control cabinet.

4. Normal production pressure grade is 2.5~6.4 MPa, higher pressure (10~20MPa) grade products will be specially designed and produced for users.

5. In explosion-proof places, device connections and electrical wiring conform to explosion-proof specifications. Its explosion-proof grade is ExdⅡB T1—T6. The explosion-proof certificate number is:

Working principle

The cold medium enters the heat exchange cavity through the inlet pipe, guides the tortuous turbulent flow along the baffle, and flows through the predetermined heat exchange process to the outlet pipe at a uniform temperature. A temperature sensor is installed in the outlet pipe of the heat exchange cavity to collect temperature signals and transmit them to the electrical control system. The electrical components of the primary loop are controlled by the temperature regulator to automatically monitor the temperature. When needed, it can be equipped with a flow blocking device. When the medium flow is relatively small, the power output of the electric heating element can be automatically stopped, and the flow can be restored to normal heating immediately when the flow increases, and a thermal element over-temperature protection device is provided.

-

1. Installation:

1.1 Reserve a space equal to the length of the heater on the front side of the gas electric heater junction box for core-pulling overhaul.

1.2 Before installation, use a 1000V shake meter to check the insulation resistance between the main terminal and the shell, insulation resistance ≥1.5MΩ, marine electric heater insulation ≥10MΩ; and check the body and each component for obvious Defect phenomenon.

1.3 During the hoisting process of the gas electric heater, the gas electric heater should be lifted and placed gently. Do not collide or fall. When laying it flat, use a skid pad on the shell. The junction box is not allowed to be stressed on the ground, and the safety valve port faces upwards. Place, the support or base is fixed on a stable and firm foundation.

1.4 The gas electric heater has been pressure tested before leaving the factory, and no parts are allowed to be disassembled without permission, and no bolts are allowed to loosen at will.

1.5 After the gas electric heater is installed and fixed, check whether the heat transfer oil added in the heating chamber is level (10Kg/barrel heat transfer oil is provided with the machine, and the commissioning service personnel of our company are responsible for guiding the first refueling.), the expansion tank is explosion-proof The plug is used to breathe the gas in the expansion box and keep the pressure in the box stable. Our company personnel have adjusted and tightened it before leaving the factory. The installer should carefully check the explosion-proof plug. No one is allowed to loosen or tighten at will during operation.

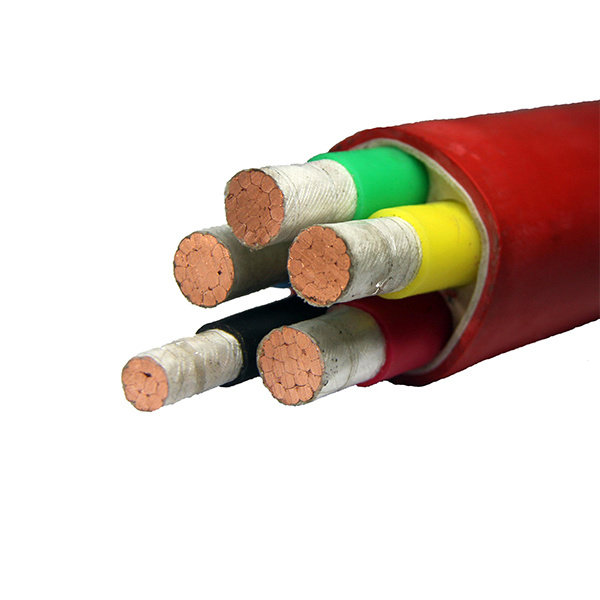

1.6 The selection of cables is carried out in accordance with relevant design specifications. The cables must be copper core wires and be firmly connected with terminal lugs.

1.7 The electric heating control cabinet produced by our factory is non-explosion-proof equipment, and should be installed outside the explosion-proof area (safe area), and conduct a comprehensive inspection during installation, and wire it correctly according to the wiring diagram provided by the factory. Set various process temperature constants according to the provisions of the temperature regulator instruction manual. Lock after setting.

1.8 The symbols on the outside of the gas electric heater base and the junction box are external grounding parts. Use 6mm2 or more stranded copper wire to ground firmly, and the grounding resistance is ≤10Ω. The electrical connection of the explosion-proof place must meet the explosion-proof requirements. After the wiring is completed, use the explosion-proof glue to seal the wire inlet from the inside of the junction box, and apply industrial petroleum jelly to the joints of the junction box.

1.9 When the on-site pressure test is performed after the heater is installed, the company’s personnel must be present, and the test pressure shall not exceed 1.25 times the working pressure on the product nameplate.

2. Trial run:

2.1 Check the insulation of the system again before trial operation; check whether the power supply voltage is consistent with the nameplate; recheck whether the electrical connection is correct.

2.2 Before the medium replaces the air, the gas electric heater opens the air outlet and closes the air inlet. (At this time, there is no combustible gas in the gas electric heater). The heater is manually powered on for 20 seconds, and the temperature of the heat exchange tube rises. Check whether the two-stage temperature display function is reliable.

2.3 Before putting into operation, it must be replaced strictly in accordance with the flammable gas replacement specification. The main power supply of the gas electric heater must be disconnected before the replacement operation.

2.4 When the gas electric heater replaces air, first open the inlet and outlet pipeline valves, close the bypass valve, and replace it normally for a period of time to ensure that the combustible medium is full and reaches the specified flow before the electric heater can manually enter the normal trial operation.

2.5 If the manual operation is normal, you can switch to the automatic operation state, operate correctly and record the voltage, current, temperature and other relevant data during operation. After 2 hours of automatic trial operation, there is no abnormal situation before the equipment handover can be arranged.

2.6 After the trial operation, if the process design requires it, the body insulation should be done in time.

3. Run

3.1 Operation and use by non-professional staff is strictly prohibited.

3.2 Regular inspections of equipment and circuits are carried out to strengthen maintenance. In particular, attention should be paid to checking electrical contacts, terminals, connectors, etc. for false connections and overheating. After opening and checking, restore the original state in time.

3.3 The electrical parameters are regularly checked and checked every year.

3.4 Before running in winter every year, replenish the heat transfer oil to the highest level. After two years of use, 500mml heat-conducting oil should be discharged from the bottom oil drain every year for testing. If the physicochemical index of the heat-conducting oil is found to exceed the regulations, it should be replaced in time (refer to the heat-conducting oil manual).

3.5 Calibrate temperature measurement sensors and temperature adjustment instruments every year in accordance with the requirements of the quality assurance system to ensure the accuracy of the measurement values.

3.6 When disabling and reactivating for a long time or relocating the place of use, the contents of items 1 and 2 shall be re-executed strictly.

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!