Container explosion-proof electric heater

The container explosion-proof electric heater (hereinafter referred to as the electric heater) is an electric heating device designed to increase the temperature of the medium in the container. The electric heater adopts mineral insulated (MI) heating cable as the heating element. It has a firm and durable structure, reliable work, long service life, and the heated medium will not be coked and charred. The electric heater is inserted and installed on the wall of the container to heat up various liquid or gaseous media. This product is widely used in petroleum, chemical, pharmaceutical, water treatment, food processing, commercial oil depot, power generation and other sectors, especially suitable for heating high-density, Medium that is viscous or requires high temperature quality (such as crude oil, asphalt, residual oil, heavy diesel oil, animal and vegetable oils, etc.). Typical applications are hot water tanks on offshore oil platforms, oil delivery tanks in commercial oil depots, etc.

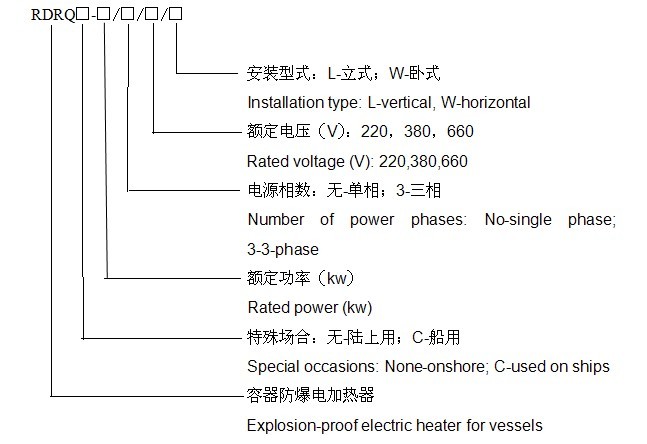

Classification:

Key words:

Container explosion-proof electric heater

- Description

- Specification

- parameter

- output power

- Application

-

- Commodity name: Container explosion-proof electric heater

- Commodity ID: 1329827717574184960

The container explosion-proof electric heater (hereinafter referred to as the electric heater) is an electric heating device designed to increase the temperature of the medium in the container. The electric heater adopts mineral insulated (MI) heating cable as the heating element. It has a firm and durable structure, reliable work, long service life, and the heated medium will not be coked and charred. The electric heater is inserted and installed on the wall of the container to heat up various liquid or gaseous media. This product is widely used in petroleum, chemical, pharmaceutical, water treatment, food processing, commercial oil depot, power generation and other sectors, especially suitable for heating high-density, Medium that is viscous or requires high temperature quality (such as crude oil, asphalt, residual oil, heavy diesel oil, animal and vegetable oils, etc.). Typical applications are hot water tanks on offshore oil platforms, oil delivery tanks in commercial oil depots, etc.

The container explosion-proof electric heater (hereinafter referred to as the electric heater) is an electric heating device designed to increase the temperature of the medium in the container. The electric heater adopts mineral insulated (MI) heating cable as the heating element. It has a firm and durable structure, reliable work, long service life, and the heated medium will not be coked and charred. The electric heater is inserted and installed on the wall of the container to heat up various liquid or gaseous media. This product is widely used in petroleum, chemical, pharmaceutical, water treatment, food processing, commercial oil depot, power generation and other sectors, especially suitable for heating high-density, Medium that is viscous or requires high temperature quality (such as crude oil, asphalt, residual oil, heavy diesel oil, animal and vegetable oils, etc.). Typical applications are hot water tanks on offshore oil platforms, oil delivery tanks in commercial oil depots, etc.

-

Table 1 Technical data and dimensions of explosion-proof electric heaters for vessels

Model

Rated power (Kw)

Rated voltage (V)

Rated current (A)

Phase number

Allowable operating pressure Mpa

Dimensions (mm) Wire inlet hole size of the junction box (mm)

Body weight (kg)

Remark

Bushing length

Heat pipe length

Flange size

Pipe size of the oil outlet port

RDRQ-3/220

3

220

13.5

1

2.5

4.0

1090

790

Φ114

DN25

DN40

Φ30×1 hole

Φ25×1 hole

85

Figure 2

RDRQ-5/220

5

220

22.5

1

1380

1080

Φ159

105

RDRQ-7.5/220

7.5

220

34

1

1610

1310

Φ219

120

RDRQ-10/3/380

10

380

15

3

3000

2800

Φ219

Φ30×2 hole

Φ25×1 hole

112

RDRQ-15/3/380

15

380

22.5

3

3200

3000

Φ219

131

RDRQ-20/3/380

20

380

30

3

3400

3200

Φ219

139

RDRQ-30/3/380

30

380

45

3

4000

3800

Φ219

Φ40×2 hole

Φ25×1 hole

147

RDRQ-50/3/380

50

380

75

3

4800

4200

Φ219

155

RDRQ-80/3/380

80

380

120

3

6000

5600

Φ219

170

-

Technical parameters:

-

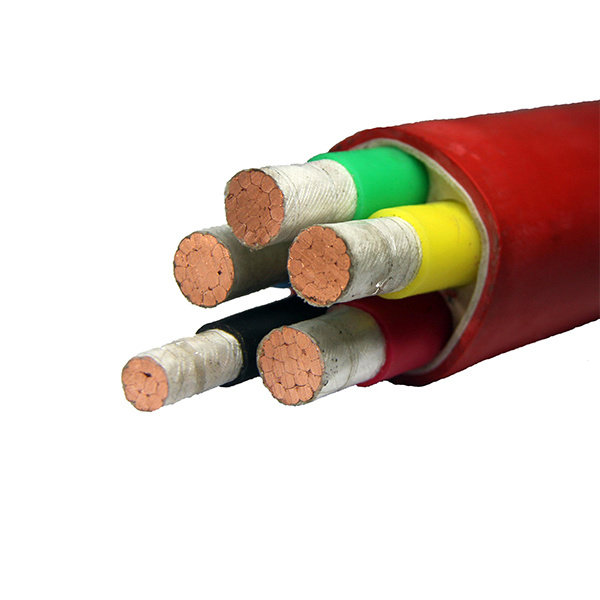

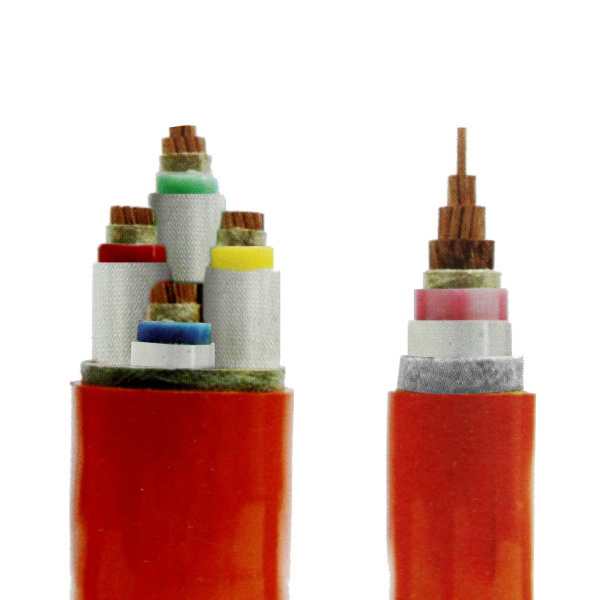

Technical performance and characteristics

1. The heating element adopts mineral insulated (MI) heating cable, which has good thermal conductivity, and the temperature difference between the heating core and the metal sheath is very small. According to the special requirements of the process, the surface heat load density of the MI heating cable can be accurately designed. Under the premise of ensuring the total heating power, the heated medium will not be coked or carbonized. It solves the long-standing shortcomings of carbon deposits, tube bursts, broken cores and short life span of traditional tubular electric heaters. The heating element can be divided into copper sheath and stainless steel sheath according to the user's use place and medium.

2. The overall structure is small and solid, with high mechanical strength, and the installation is an insert immersion type.

3. The electric heater generates heat evenly, and the heat exchange efficiency is high.

4. The design of the electric heater meets the structural requirements and geometric shapes of various types of storage containers for petroleum and chemical products. The device connection and electrical connection meet the explosion-proof requirements, and the explosion-proof grade is dⅡB T1~T6.

5. Reliable work, long service life, convenient operation and maintenance, and daily maintenance is not required.

6. The electric heater has good corrosion resistance to petroleum and chemical industry and its finished products.

7. The body has good pressure-bearing and sealing performance, and is safe to use. The working pressure is 2.5MPa~6.4MPa. Higher pressure can be customized.

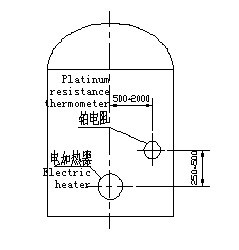

8. A temperature sensor is installed in the body to detect the temperature of the oil, overheating of the oil, and the surface temperature of the heating element.

9. The product is highly adaptable and practical, and non-standard electric heaters can be designed according to different uses and special requirements put forward by users.

Working principle

When the electric heater is turned on, the temperature of the medium rises along the heating element (heating cable) and then naturally rises, and the cold medium flows in and supplements around the heating element. This repeated heat difference convection cycle makes the temperature of the medium heat up The time is gradually increased until the specified medium temperature is reached. A temperature sensor is installed on the wall of the container to collect the temperature signal and transmit it to the electric control system. The primary circuit is controlled by the temperature adjustment instrument to realize the automatic temperature control of the oil product temperature. After the electric heater is overheated by the oil or heating element, the protection device will automatically cut off the power supply, and the control cabinet will send out an audible and visual alarm signal at the same time (see the company's WK series electric heating control cabinet instruction manual for details).

-

1. Electric heater installation:

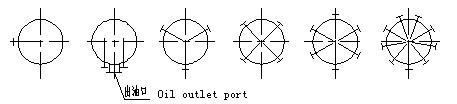

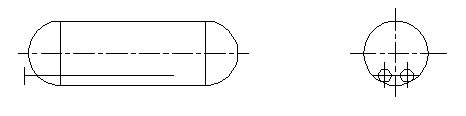

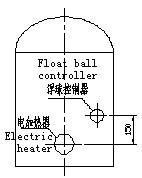

1.1 Before installation, check whether the electric heater equipment that has been transported over long distances has appearance defects, and use a 1000V shaker to measure the insulation resistance between the conductive part and the shell 1.5~10MΩ. The arrangement of the electric heater in the storage tank is shown in Figure 2 and Figure 3:

Figure 2: Plane layout of RDRQ electric heater on vertical oil tank

Figure 3: Horizontal installation of RDRQ electric heater on horizontal oil tank

1.2 The RDRQ electric heater is installed horizontally. A space equal to the length of the heater is reserved on the front side of the heater junction box to prepare for maintenance.

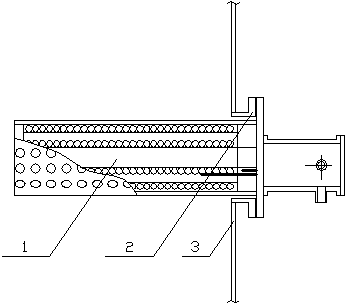

Weld the installation puppet on the oil tank first (whether there is a reinforcement ring on the tank wall is determined by the process design, the installation puppet is provided by the factory, and the specifications are shown in Table 1), and the electric heater is installed on the puppet The connecting flange is installed on the tank, and an oil-resistant asbestos rubber gasket should be added between the two flanges, and the bolt connection should be fastened without leakage (see Figure 4). The inlet of the junction box must be installed downwards. The highest position of the electric heater body must be controlled below the lowest working liquid level of the oil tank process design.

The electric heater is equipped with a special grounding bolt. The user should reliably connect the grounding wire to the bolt, and the grounding wire should be used

Multi-strand copper wires above 4mm2, grounding resistance ≤10Ω. After the electrical wiring is completed, the joints of the junction box must be coated with industrial petroleum jelly

Ensure that the seal is intact.

1. Electric heater 2. Factory matching installation short section ⒊oil tank wall

2. Supporting device installation:

2.1 Control cabinet installation and electrical wiring:

Non-explosion-proof electric heating control cabinet should be installed outside the explosion-proof area (safe area). The box body should be vertical when installing, and the grounding wire should be firm and reliable. The floor type requires anchor bolts to fix the box on the foundation.

According to the requirements of explosion-proof regulations, copper core cables are required for power cables and control cables, and their cross-sections should be selected according to the power of the electric heater (the actual cable cross-section should be re-checked by the design according to the voltage drop), and according to the manufacturer The provided wiring diagram is correctly wired.

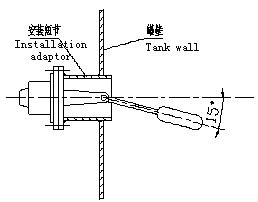

2.2 Installation of temperature measuring resistance:

Because the oil in the tank presents a non-uniform temperature field, the relative position of the temperature measuring resistor and the electric heater should be selected to reflect the true temperature of the oil inside the tank. It is recommended to install it according to the position shown in Figure 5. .

Installation method: The temperature measuring resistor is installed in the steel sheathing tube, and the steel sheathing tube is welded to the wall of the oil tank. It is inclined downwards during installation and forms an angle of 15 degrees with the horizontal (see Figure 6). Add an appropriate amount to the casing After the transformer oil and the temperature measuring resistor are inserted into the steel sheathed tube, they are fastened with positioning screws.

2.3 Installation of the liquid level controller: the relative position of the liquid level controller and the electric heater (see figure 7), provided by the product manufacturer, flange pipe with an outer diameter of Φ90mm (see figure 8) Weld horizontally on the wall of the oil tank, and install the level controller on the flange pipe. Oil-resistant asbestos rubber gaskets should be used between the flanges.

Figure 5: Relative position of temperature measuring resistor and electric heater installation

Picture 6: The temperature measuring resistor is installed on the oil tank

Figure 7: Relative position of liquid level controller and electric heater

Picture 8: The installation of the level controller on the oil tank

Note: When determining the relative positions of the electric heater, float level controller, and temperature measuring resistor, it is recommended that the lowest position of the level controller is 150mm higher than the upper surface of the electric heater, and should be higher than the platinum heater. The lowest end of the resistor is 100mm.

2.4 Installation of heating chamber for commercial oil tanks: The characteristics of commercial oil tanks are: unplanned, irregular, and small in quantity. Therefore, the use of electric heat tracing for heat preservation of the entire commercial oil tank consumes energy and is uneconomical, and the management is also complicated. A heating chamber with a certain capacity is designed in the oil tank, and an electric heater is installed in it. When the customer sends a request for oil purchase, the electric heater is operated to heat the medium in the heating chamber. After the customer has completed the procedures for purchasing the oil, the oil can be sent.

Picture 9: Installation of RDRQ electric heater in the oil tank heating cabin

3. Trial run:

3.1 Check before trial operation:

Check whether the installation position of the electric heater and supporting components is correct, whether the connecting bolts are loose, whether the grounding is reliable, and whether the grounding resistance is qualified. Check whether the electrical wiring conforms to the drawing, whether the wiring process meets the installation requirements, and whether the bolt connection is firm. Use a 1000V shaker to check whether the live part and the shell are well insulated, the insulation resistance is ≥1.5MΩ, the insulation resistance of the marine electric heater is ≥10MΩ, and check whether the power supply voltage is consistent with the product nameplate. Check whether the over-temperature protection sensor is connected. The over-temperature protector has been set at the temperature according to the explosion-proof regulations at the factory, and no further adjustment is required. Check whether the oil level in the oil tank is higher than the top of the electric heater. ,

3.2 Trial run:

Set various process temperature limit values according to the temperature regulator manual. After the transfer switch is set to the manual position, the power is turned on and the trial operation is started. After running in the manual position for 10 minutes, the condition is normal, you can turn the switch to the automatic position, and the equipment is put into automatic operation. Operate correctly according to the operating instructions in the accompanying drawings and documents of the equipment, and record the relevant data such as voltage, current, and temperature during operation. After the trial run for 2 hours, there is no abnormal situation before it can be transferred to the formal operation.

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!