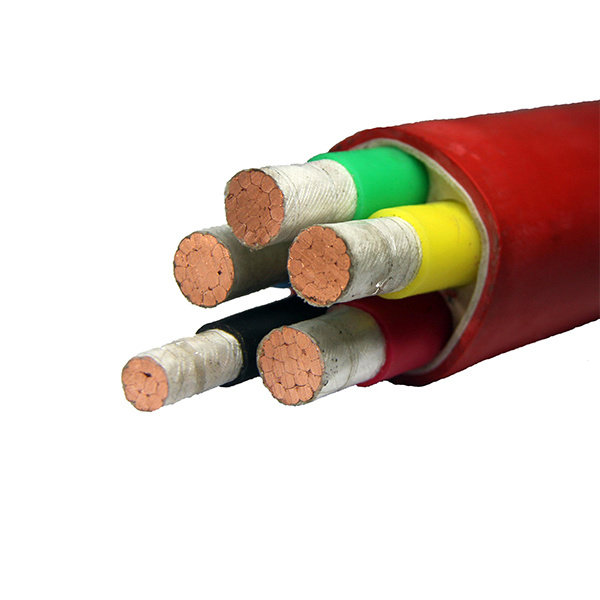

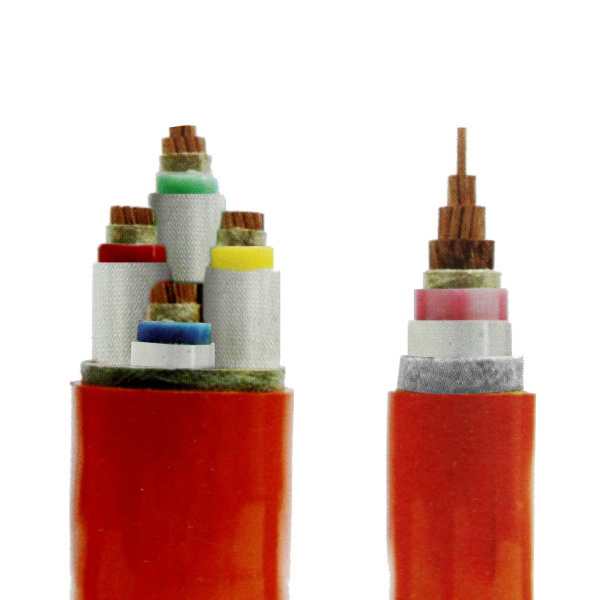

Wire and Cable

This product is suitable for fixed connection wires of electrical equipment with rated voltages of 450/750V and below, copper core PVC insulated connections for household appliances, small electric tools, instruments and power lighting used for AC rated voltages of 450/750V and below. electric wire.

Classification:

Key words:

Wire and Cable

- Description

- Model and specification

- Usage characteristics

- Parameter

- Transportation

-

- Commodity name: Wire and Cable

- Commodity ID: 1329827706782240768

This product is suitable for fixed connection wires of electrical equipment with rated voltages of 450/750V and below, copper core PVC insulated connections for household appliances, small electric tools, instruments and power lighting used for AC rated voltages of 450/750V and below. electric wire.

This product is suitable for copper core PVC insulation for electrical equipment with rated voltages of 450/750V and below, household appliances with AC rated voltages of 450/750V and below, small power tools, instruments and power lighting. Flexible wire for connection

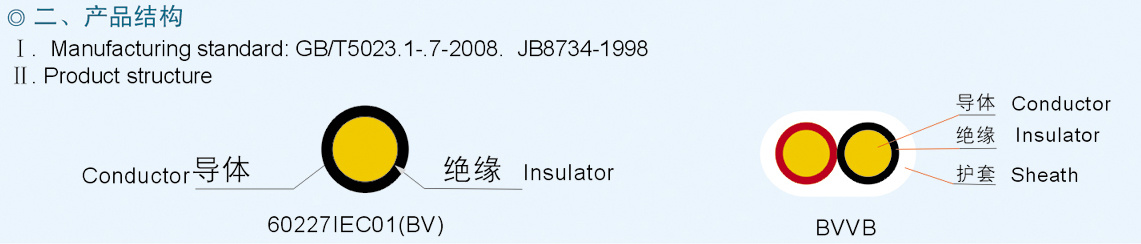

Executive standard: GB5023.1-.7-2008, JB8734-1998

Product structure:

-

Model and name

Model

Name

Voltage class

VManufacturing standard

Core number

Cross section

mm2Application Situation

60227IEC01(BV)

General purpose sheathless cable of single core hard conductor

450/750

GB5023.3-1997

1

1.5-400

Permanent wiring

60227IEC05(BV)

Sheathless cable of single core solid conductor, used for internal wiring with conductor temperature 70℃

300/500

GB5023.3-1997

1

0.5-1

Permanent wiring

60227IEC07(BV-90)

Sheathless cable of single core solid conductor, used for internal wiring with conductor temperature 90℃

300/500

GB5023.3-1997

1

0.5-2.5

Permanent wiring

60227IEC10(BVV)

Cable with light PVC sheath

300/500

GB5023.4-1997

2-5

1.5-35

Permanent wiring

BV

PVC insulated wire with copper core

300/500

JB8734

1

0.75-1

Permanent wiring

BLV

PVC insulated cable with aluminum core

450/750

JB8734

1

2.5-400

Permanent wiring

BVR

PVC insulated flexible cable with copper core

450/750

JB8734

1

2.5-70

Permanent wiring with requirement of flexible situation

BVV

PVC insulated round cable with copper core and PVC sheath

300/500

JB8734

1

0.75-10

Permanent wiring

BLVV

PVC insulated round cable with aluminum core and PVC sheath

300/500

JB8734

1

2.5-10

Permanent wiring

BVVB

PVC insulated flat cable with copper core and PVC sheath

300/500

JB8734

2,3

0.75-10

Permanent wiring

BLVVB

PVC insulated flat cable with aluminum core and PVC sheath

300/500

JB8734

2,3

2.5-10

Permanent wiring

60227IEC02 (RV)

General purpose sheathless cable of single core flexible conductor

450/750

GB5023.3-1997

1

1.5-240

60227IEC06(RV)

Sheathless cable of single core flexible conductor, used for internal wiring with conductor temperature 70℃

300/500

GB5023.3-1997

1

0.5-1

60227IEC08(RV-90)

Sheathless cable of single core solid conductor, used for internal wiring with conductor temperature 90℃

300/500

GB5023.3-1997

1

0.5-2.5

60227IEC42(RVB)

Flat sheathless flexible wire

300/300

GB5023.5-1997

2

0.5-0.75

60227IEC53(RVV)

Flexible wire of ordinary PVC sheath

300/500

GB5023.5-1997

2-5

0.75-2.5

RVS

Stranded connecting flexible cable of copper core and PVC insulation

300/300

JB8734

1

0.5-0.75

Product representation method

Products are represented by model, specification and standard number. Specifications include rated voltage, number of cores, and conductor cross-section.

The color of the cable, if necessary, should be indicated at the end of the specification.

For example: General purpose single-core hard conductor non-sheathed cable, for fixed wiring, rated voltage 450/750V, 1 core, 4mm2 blue means 227IEC01 (BV) 450/750V1*4 blue GB5023.3-2008 -

Main performance parameters of finished cables

The electrical performance of the cable should meet the requirements of Table 8

Electrical performance of the cableNo.

Test item

Unit

Rated voltage of cable

Test method

300/300V

300/500V

450/750V

GB

Clause No.

1

Resistance test of conductor

5023.2

2.1

1.1

Test result

Please refer to tables 5 and 7

Please refer to tables 3, 4 and 6

Please refer to table 2

Maximum value

2

Voltage test of finished cable

5023.2

2.2

2.1

Test condition

Min. length of specimen

m

10

10

10

Min. time of dipping in water

h

1

1

Water temperature

℃

20±5

20±5

20±5

2.2

Testing voltage (AC)

V

2000

2000

2000

2.3

Min. voltage applying time at one time

min

5

5

5

2.4

Test result

No breakdown

No breakdown

No breakdown

3

Voltage test of insulation wire core

5023.2

2.3

3.1

Test condition

Length of specimen

m

5

5

5

Min. time of dipping in water

h

1

1

1

Water temperature

℃

20±5

20±5

20±5

3.2

Testing voltage (AC)

With insulation thickness 0.6mm or below

V

1500

1500

-

With insulation thickness 0.6mm or above

V

2000

2000

2500

3.3

Min. voltage applying time at one time

min

5

5

5

3.4

Test result

No breakdown

No breakdown

No breakdown

4

Insulation resistance measurement

5023.2

2.4

4.1

Test condition

Length of specimen

m

5

Through the above items 2 and 3 voltage test

Min. time of dipping in hot water

h

2

Water temperature

4.2

Test result

Please refer to tables 5 and 7

Please refer to tables 3,4 and 6

Please refer to table 2

Outer dimensions: The average outer dimensions of the cable should meet the requirements of Table 2 to Table 7. The difference between the outer diameters of any two points measured on the same cross section of the round cable should not exceed 15% of the upper limit of the average outer diameter

Mechanical strength of flexible cables

Flexible cables should be able to withstand bending and other mechanical stresses during normal use.

The bending test of the flexible cable should be able to withstand 15,000 reciprocating motions. That is, after 30,000 single-way movements, neither current short circuit nor short circuit between conductors should occur.

Non-flammability test: All cables should meet the test requirements specified in GB/T18380.1. -

Table 2. Comprehensive data of 60227IEC01 (BV) 450/750V general purpose single-core hard conductor non-sheathed cable

Comprehensive data of 60227IEC01(BV) 450/750V general purpose single-core hard conductor non-sheathed cable

Nominal cross section of conductormm2

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

1.5

1

0.7

3.3

0.011

12.1

20

1.5

2

0.7

3.4

0.010

12.1

21

2.5

1

0.8

3.9

0.010

7.41

33

2.5

2

0.8

4.2

0.009

7.41

34

4

1

0.8

4.4

0.0085

4.61

48

4

2

0.8

4.8

0.0077

4.61

50

6

1

0.8

4.9

0.0070

3.08

68

6

2

0.8

5.4

0.0065

3.08

70

10

1

1.0

6.4

0.0070

1.83

113

10

2

1.0

6.8

0.0065

1.83

115

16

2

1.0

8.0

0.0050

1.15

174

25

2

1.2

9.8

0.0050

0.727

271

35

2

1.2

11.0

0.0040

0.524

368

50

2

1.4

13.0

0.0045

0.387

522

70

2

1.4

15.0

0.0035

0.268

714

95

2

1.6

17.0

0.0035

0.193

968

120

2

1.6

19.0

0.0032

0.153

1206

150

2

1.8

21.0

0.0032

0.124

1507

185

2

2.0

23.5

0.0032

0.0991

1860

240

2

2.2

26.5

0.0032

0.0754

2405

300

2

2.4

29.5

0.0030

0.0601

2998

400

2

2.6

33.5

0.0028

0.0470

3936

Table 2-1, 60227IEC02 (RV) type 450/750V general purpose single-core soft conductor unsheathed cable comprehensive data

Comprehensive data of 227IEC01(BV) 450/750V general purpose single-core hard conductor non-sheathed cable

Nominal cross section of conductormm2

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

1.5

1

0.7

3.3

0.011

12.1

20

1.5

2

0.7

3.4

0.010

12.1

21

2.5

1

0.8

3.9

0.010

7.41

33

2.5

2

0.8

4.2

0.009

7.41

34

4

1

0.8

4.4

0.0085

4.61

48

4

2

0.8

4.8

0.0077

4.61

50

6

1

0.8

4.9

0.0070

3.08

68

6

2

0.8

5.4

0.0065

3.08

70

10

1

1.0

6.4

0.0070

1.83

113

10

2

1.0

6.8

0.0065

1.83

115

16

2

1.0

8.0

0.0050

1.15

174

25

2

1.2

9.8

0.0050

0.727

271

35

2

1.2

11.0

0.0040

0.524

368

50

2

1.4

13.0

0.0045

0.387

522

70

2

1.4

15.0

0.0035

0.268

714

95

2

1.6

17.0

0.0035

0.193

968

120

2

1.6

19.0

0.0032

0.153

1206

150

2

1.8

21.0

0.0032

0.124

1507

185

2

2.0

23.5

0.0032

0.0991

1860

240

2

2.2

26.5

0.0032

0.0754

2405

300

2

2.4

29.5

0.0030

0.0601

2998

400

2

2.6

33.5

0.0028

0.0470

3936

Table 2-1, 60227IEC02 (RV) type 450/750V general purpose single-core soft conductor unsheathed cable comprehensive data

Table 2 60227IEC02 (RV) type 450/750V general purpose single-core soft conductor unsheathed cable comprehensive data

Nominal cross section of conductormm2

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

1.5

5

0.7

3.5

0.01

13.3

22.1

2.5

5

0.8

4.2

0.009

7.98

34.5

4

5

0.8

4.8

0.007

4.95

50.2

6

5

0.8

6.3

0.006

3.3

73.6

10

5

1

7.6

0.0056

1.91

119.4

16

5

1

8.8

0.0046

1.21

178.7

25

5

1.2

11

0.0044

0.78

277.3

35

5

1.2

12.5

0.0038

0.554

375.3

50

5

1.4

14.5

0.0037

0.386

531.5

70

5

1.4

17

0.0032

0.272

727.1

95

5

1.6

19

0.0032

0.206

978.6

120

5

1.6

21

0.0029

0.161

1217.7

150

5

1.8

23.5

0.0029

0.129

1523.2

185

5

2

26

0.0029

0.106

1877.9

240

5

2.2

29.5

0.0028

0.0801

2426.3

注:

1. Conductor structure: According to the fifth conductor of GB/T3956.

2. Insulation: the insulating material should be PVC/C type polyvinyl chloride mixture.

3. The average outer diameter is not greater than the upper limit specified in the table

Table 3 60227IEC05(BV) type 300/500V internal wiring with conductor temperature of 70℃ single-core solid conductor unsheathed cable comprehensive data

Nominal cross section of conductormm2

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

0.5

1

0.6

2.4

0.015

36.0

8.8

0.75

1

0.6

2.6

0.012

24.5

12.0

1.0

1

0.6

2.8

0.011

18.1

14.5

Note:

1. Conductor structure: Choose according to GB/T3956, use the first type for solid conductors and use the second type for stranded conductors.

2. Insulation: PVC/C type polyvinyl chloride mixture should be used as the insulating material.

3. The average outer diameter is not greater than the upper limit specified in the table.Table 3 227IEC06(RV) type 300/500V internal wiring with conductor temperature of 70℃ single-core soft conductor unsheathed cable comprehensive data

Nominal cross section of conductor mm2

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

0.5

5

0.6

2.6

0.013

39

9.8

0.75

5

0.6

2.8

0.011

26

12.6

1

5

0.6

3

0.01

19.5

15.4

Note:

1. Conductor structure: According to the fifth conductor of GB/T3956.

2. Insulation: The insulating material should be PVC/C type polyvinyl chloride mixture.

3. The average outer diameter is not greater than the upper limit specified in the tableTable 4 227IEC07(BV-90) type 300/500V internal wiring with conductor temperature of 90℃ single-core solid conductor unsheathed cable comprehensive data

Nominal cross section of conductormm²

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

0.75

1

0.6

2.6

0.013

24.5

11.5

1.0

1

0.6

2.8

0.012

18.1

14.5

1.5

1

0.7

3.3

0.011

12.1

21.0

2.5

1

0.8

3.9

0.009

7.41

33.0

Note:

1. Conductor structure: Choose according to GB/T3956, use the first type for solid conductors and use the second type for stranded conductors.

2. Insulation: PVC/C type polyvinyl chloride mixture should be used as the insulating material.

3. The average outer diameter is not greater than the upper limit specified in the table.Table 4 227IEC08 (RV-90) type 300/500V internal wiring with conductor temperature of 90℃ single-core soft conductor unsheathed cable comprehensive data

Nominal cross section of conductor mm²

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

0.5

5

0.6

2.6

0.013

39

9.8

0.75

5

0.6

2.8

0.011

26

12.6

1

5

0.6

3

0.01

19.5

15.4

1.5

5

0.7

3.5

0.009

13.3

22.1

2.5

5

0.8

4.2

0.009

7.98

34.5

Note:

1. Conductor structure: According to the fifth conductor of GB/T3956.

2. Insulation: the insulating material should be PVC/C type polyvinyl chloride mixture.

3. The average outer diameter is not greater than the upper limit specified in the tableTable 5 Comprehensive data of BV type 300/500V copper core PVC insulated wire

Nominal cross section of conductormm²

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

0.75

1

0.6

2.6

0.014

24.5

12.0

1.0

1

0.6

2.8

0.013

18.1

15.0

Note:

1. Insulation: the insulating material should be PVC/C type polyvinyl chloride mixture

2, the average outer diameter is not greater than the upper limit specified in the table

Table 5 General data of 227IEC42(RVB) 300/300V flat non-sheathed flexible cord

Nominal cross section of conductor mm2

Minimum number of single line in the stranded conductor

Rated value of insulation thickness mm

Average overall diameter mm

Minimum insulation resistance under temperature 70℃ MΩ/km

Maximum DC resistance under temperature Ω/km

Theoretical weight kg/km

Lower limit

Upper limit

0.5

6

0.8

2.5*5.0

3.0*6.0

0.016

39

22.5

0.75

6

0.8

2.7*5.4

3.2*6.4

0.014

26

28.5

Note:

1. Conductor structure: According to the fifth conductor of GB/T3956.

2. Insulation: The insulating material should be PVC/C type polyvinyl chloride mixture.

3. The average outer diameter is not greater than the upper limit specified in the tableTable 6 Comprehensive data of BVR type 450/750V copper core PVC insulated flexible cable

Nominal cross section of conductormm2

Conductor type

Rated value of insulation thicknessmm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃MΩ.km

Maximum DC resistance under temperature 20℃Ω/km

Theoretical weightkg/km

2.5

19

0.8

4.1

0.011

7.41

34.0

4

19

0..8

4.8

0.009

4.61

49.7

6

19

0.8

5.3

0.0084

3.08

70.1

10

49

1.0

6.8

0.0072

1.83

118.5

16

49

1.0

8.1

0.0062

1.15

177.9

25

98

1.2

10.2

0.0058

0.727

274.9

35

133

1.2

11.7

0.0052

0.524

374.9

50

133

1.4

13.9

0.0051

0.387

531.1

70

189

1.4

16.0

0.0045

0.268

727.3

Note:

1. Insulation: the insulating material should be PVC/C type polyvinyl chloride mixture

2, the average outer diameter is not greater than the upper limit specified in the table

Table 6 Comprehensive data of 2227IEC53 (RVV) type 300/500V ordinary PVC sheathed flexible cord

Nominal cross section of conductor mm²

Minimum number of single line in the stranded conductor

Rated value of insulation thickness mm

Rated value of sheath thickness mm

Average overall diameter mm

Minimum insulation resistance under temperature 70℃ MΩ/km

Maximum DC resistance under temperature Ω/km

Theoretical weight kg/km

Lower limit

Upper limit

2*1.0

5

0.6

0.8

6.4

8

0.01

19.5

69.9

2*1.5

5

0.7

0.8

7.4

9

0.01

13.3

87.1

2*2.5

5

0.8

1

8.9

11

0.009

7.98

126.1

3*1.0

5

0.6

0.8

6.8

8.4

0.01

19.5

95.7

3*1.5

5

0.7

0.9

8

9.8

0.01

13.3

107.8

3*2.5

5

0.8

1

9.6

12

0.009

7.98

161.7

4*1.0

5

0.6

0.9

7.6

9.4

0.01

19.5

111.7

4*1.5

5

0.7

1

9

11

0.01

13.3

148.3

4*2.5

5

0.8

1.1

10.5

13

0.009

7.98

215

5*1.0

5

0.6

0.9

8.3

10

0.01

19.5

134.3

5*1.5

5

0.7

1.1

10

12

0.01

13.3

173.6

5*2.5

5

1

1.2

11.5

14

0.009

7.98

259.8

Note:

1. Conductor structure: According to the fifth type of conductor in GB/T3956.

2. Insulation: the insulating material should be PVC/D type polyvinyl chloride mixture.

3. Sheath: PVC/ST5 type polyvinyl chloride mixture should be used

4. The average outer diameter should be within the limit specified in the tableTable 7 General data of 227IE10(BVV) 300/500V light PVC sheathed cable

Core number * nominal cross section mm2

Conductor type

Rated value of insulation thickness mm

Rated value of sheath thickness mm

Average overall diameter mm

Minimum insulation resistance under temperature 70℃ MΩ/km

Maximum DC resistance under temperature Ω/km

Theoretical weight kg/km

Lower limit

Upper limit

2*1.5

1

0.7

1.2

7.6

10.0

0.011

12.1

121

2*1.5

2

0.7

1.2

7.8

10.5

0.010

12.1

127

2*2.5

1

0.8

1.2

8.6

11.5

0.010

7.41

158

2*2.5

2

0.8

1.2

9.0

12.0

0.009

7.41

166

2*4

1

0.8

1.2

9.6

12.5

0.0085

4.61

198

2*4

2

0.8

1.2

10.0

13.0

0.0077

4.61

208

2*6

1

0.8

1.2

10.5

13.5

0.0070

3.08

249

2*6

2

0.8

1.2

11.0

14.0

0.0065

3.08

260

2*10

1

1.0

1.4

13.0

16.5

0.0070

1.83

381

2*10

2

1.0

1.4

13.5

17.5

0.0065

1.83

397

2*16

2

1.0

1.4

15.5

20.0

0.0052

1.15

540

2*25

2

1.2

1.4

18.5

24.0

0.0050

0.727

772

2*35

2

1.2

1.6

21.0

27.5

0.0044

0.524

1044

3*1.5

1

0.7

1.2

8.0

10.5

0.011

12.1

146

3*1.5

2

0.7

1.2

8.2

11.0

0.010

12.1

153

3*2.5

1

0.8

1.2

9.2

12.0

0.010

7.41

196

3*2.5

2

0.8

1.2

9.4

12.5

0.009

7.41

206

3*4

1

0.8

1.2

10.0

13.0

0.0085

4.61

252

3*4

2

0.8

1.2

10.5

13.5

0.0077

4.61

264

3*6

1

0.8

1.4

11.5

14.5

0.0070

3.08

338

3*6

2

0.8

1.4

12.0

15.5

0.0065

3.08

353

3*10

1

1.0

1.4

14.0

17.5

0.0070

1.83

504

3*10

2

1.0

1.4

14.5

19.0

0.0065

1.83

523

3*16

2

1.0

1.4

16.5

21.5

0.0052

1.15

727

3*25

2

1.2

1.4

20.5

26.0

0.0050

0.727

1059

3*35

2

1.2

1.6

22.0

29.0

0.0044

0.524

1433

4*1.5

1

0.7

1.2

8.6

11.5

0.011

12.1

175

4*1.5

2

0.7

1.2

9.0

12.0

0.010

12.1

182

4*2.5

1

0.8

1.2

10.0

13.0

0.010

7.41

238

4*2.5

2

0.8

1.2

10.0

13.5

0.009

7.41

250

4*4

1

0.8

1.4

11.5

14.5

0.0085

4.61

325

4*4

2

0.8

1.4

12.0

15.0

0.0077

4.61

340

4*6

1

0.8

1.4

12.5

16.0

0.0070

3.08

419

4*6

2

0.8

1.4

13.0

17.0

0.0065

3.08

437

4*10

1

1.0

1.4

15.5

19.0

0.0070

1.83

633

4*10

2

1.0

1.4

16.0

20.5

0.0065

1.83

657

4*16

2

1.0

1.4

18.0

23.5

0.0052

1.15

923

4*25

2

1.2

1.6

22.5

28.5

0.0050

0.727

1411

4*35

2

1.2

1.6

24.5

32.0

0.0044

0.524

1836

5*1.5

1

0.7

1.2

9.4

12.0

0.011

12.1

204

5*1.5

2

0.7

1.2

9.8

12.5

0.010

12.1

213

5*2.5

1

0.8

1.2

11.0

14.0

0.010

7.41

281

5*2.5

2

0.8

1.2

11.0

14.5

0.009

7.41

295

5*4

1

0.8

1.4

12.5

16.0

0.0085

4.61

386

5*4

2

0.8

1.4

13.0

17.0

0.0077

4.61

403

5*6

1

0.8

1.4

13.5

17.5

0.0070

3.08

501

5*6

2

0.8

1.4

14.5

18.5

0.0065

3.08

522

5*10

1

1.0

1.4

17.0

21.0

0.0070

1.83

765

5*10

2

1.0

1.4

17.5

22.0

0.0065

1.83

792

5*16

2

1.0

1.6

20.5

26.0

0.0052

1.15

1146

5*25

2

1.2

16

24.5

31.5

0.0050

0.727

1716

5*35

2

1.2

1.6

27.0

35.0

0.0044

0.524

2276

Note:

1. Conductor structure: Choose according to GB/T3956, use the first type for solid conductors and use the second type for stranded conductors.

2. Insulation: The insulating material should be PVC/C type polyvinyl chloride mixture.

3. Sheath: The sheath squeezed on the inner sheath should be made of PVC.ST4 type polyvinyl chloride mixture.

4. The average outer diameter should be within the limit specified in the table

Table 7 Comprehensive data of RVS type 300/300V copper PVC insulated stranded flexible cable for connection

Core number * nominal cross section mm²

Maximum diameter of single line in the conductor mm

Rated value of insulation thickness mm

Upper value of average overall diameter mm

Minimum insulation resistance under temperature 70℃ MΩ.km

Maximum DC resistance under temperature 20℃ Ω/km

Theoretical weight kg/km

2*0.5

0.16

0.8

6

0.016

39

22.5

2*0.75

0.16

0.8

6.2

0.014

26

28.5

Note:

1. Conductor structure: According to the fifth type of conductor in GB/T3956.

2. Insulation: the insulating material should be PVC/D type polyvinyl chloride mixture.

3. Sheath: PVC/ST5 type polyvinyl chloride mixture should be used

4. The average outer diameter should be within the limit specified in the tableTable 8 Comprehensive data of BVV type 300/500V copper core PVC insulated PVC sheathed round cable

Nominal cross section of conductor mm²

Minimum number of single line in the stranded conductor

Rated value of insulation thickness mm

Rated value of sheath thickness mm

Average overall diameter mm

Minimum insulation resistance under temperature 70℃ MΩ/km

Maximum DC resistance under temperature Ω/km

Theoretical weight kg/km

Lower limit

Upper limit

1.5

1

0.7

0.8

4.2

5.0

0.011

12.1

36

1.5

7

0.7

0.8

4.3

5.2

0.010

12.1

37

2.5

1

0.8

0.8

4.8

5.7

0.010

7.41

50

2.5

7

0.8

0.8

4.8

5.9

0.009

7.41

53

4

1

0.8

0.9

5.4

6.5

0.0085

4.61

70

4

7

0.8

0.9

5.5

6.8

0.0077

4.61

73

6

1

0.8

0.9

5.9

7.1

0.0070

3.08

93

6

7

0.8

0.9

6.0

7.3

0.0065

3.08

96

10

1

1.0

0.9

7.3

8.8

0.0065

1.83

148

Note:

1. Insulation: The insulating material should be PVC/C type polyvinyl chloride mixture.

2, sheath: the sheath on the inner sheath should be PVC.ST4 type polyvinyl chloride mixture

3. The average outer diameter should be within the limit specified in the table

Table 9 Comprehensive data of BVVB type 300/500V copper core PVC insulated PVC sheathed flat cable

Nominal cross section of conductor mm²

Minimum number of single line in the stranded conductor

Rated value of insulation thickness mm

Rated value of sheath thickness mm

Average overall diameter mm

Minimum insulation resistance under temperature 70℃ MΩ/km

Maximum DC resistance under temperature Ω/km

Theoretical weight kg/km

Lower limit

Upper limit

1.5

1

0.7

0.8

4.2

5.0

0.011

12.1

36

1.5

7

0.7

0.8

4.3

5.2

0.010

12.1

37

2.5

1

0.8

0.8

4.8

5.7

0.010

7.41

50

2.5

7

0.8

0.8

4.8

5.9

0.009

7.41

53

4

1

0.8

0.9

5.4

6.5

0.0085

4.61

70

4

7

0.8

0.9

5.5

6.8

0.0077

4.61

73

6

1

0.8

0.9

5.9

7.1

0.0070

3.08

93

6

7

0.8

0.9

6.0

7.3

0.0065

3.08

96

10

1

1.0

0.9

7.3

8.8

0.0065

1.83

148

Note:

1. Insulation: The insulating material should be PVC/C type polyvinyl chloride mixture.

2. Sheath: The sheath squeezed on the inner sheath should be made of PVC.ST4 polyvinyl chloride mixture.

3. The average outer diameter should be within the limit specified in the table -

Delivery length

The length of the loop is 100 meters, and the length of the coil should be greater than 100 meters.

For short-segment deliveries with a length of not less than 20 meters, the quantity should not exceed 10% of the total length of the delivery, and the number of short-segments out of 2 should not exceed 5.

According to the agreement between the two parties, delivery of any length is allowed.

Length measurement error should not exceed ±0.5%

Finished cable delivery mark

The finished cable should have continuous marks of the manufacturer's name, product model, specification, and rated voltage printed with ink or embossed on the insulation or sheath.

The signs should have continuity, and the distance between the end of one sign on the insulated wire and the beginning of the next sign should not exceed 200mm, and the distance between the end of the next sign on the insulated wire should not exceed 500mm. The handwriting should be clear and durable

Previous

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!