Medium and high voltage cables

Cross-linked polyethylene insulated power cables use chemical or physical methods to transform polyethylene molecules from linear molecular structures to three-dimensional network structures; from thermoplastic polyethylene to thermosetting cross-linked polyethylene, which greatly improves Improved its heat resistance and mechanical properties, and maintained excellent electrical properties. The conductor working temperature of the cross-linked polyethylene insulated power cable is 90°C, and it has the characteristics of simple structure, light weight and chemical resistance, easy to use, and not restricted by the installation drop. The cables are used in power frequency voltage U0/U6/6 (6/10), 8.7/10 (8.7/15), 12/20, 26/35 (26/45) kV power transmission and distribution systems.

Classification:

Key words:

Medium and high voltage cables

- Description

- Model and specification

- Usage characteristics

- Parameter

- Transportation

-

- Commodity name: Medium and high voltage cables

- Commodity ID: 1329827708283801600

Cross-linked polyethylene insulated power cables use chemical or physical methods to transform polyethylene molecules from linear molecular structures to three-dimensional network structures; from thermoplastic polyethylene to thermosetting cross-linked polyethylene, which greatly improves Improved its heat resistance and mechanical properties, and maintained excellent electrical properties. The conductor working temperature of the cross-linked polyethylene insulated power cable is 90°C, and it has the characteristics of simple structure, light weight and chemical resistance, easy to use, and not restricted by the installation drop. The cables are used in power frequency voltage U0/U6/6 (6/10), 8.7/10 (8.7/15), 12/20, 26/35 (26/45) kV power transmission and distribution systems.

Standard

This product is based on GB/T12706.2 "Rated voltage 1kV (Um=1.2kV) to 35kV (Um=40.5kV) extruded insulated power cables and accessories Part 2: Rated voltage 6 kV (Um=7.2kV) and 30kV ( Um=36kV) cable" and GB/T12706.3 "Rated voltage 1kV (Um=1.2kV) to 35kV (Um=40.5kV) extruded insulated power cable and accessories Part 3: Rated voltage 35kV (Um=40.5kV) Cable" production.

Features and uses

Cross-linked polyethylene insulated power cables use chemical or physical methods to transform polyethylene molecules from linear molecular structures to three-dimensional network structures; from thermoplastic polyethylene to thermosetting cross-linked polyethylene, which greatly improves Improved its heat resistance and mechanical properties, and maintained excellent electrical properties.

The conductor working temperature of the cross-linked polyethylene insulated power cable is 90°C, and it has the characteristics of simple structure, light weight and chemical resistance, easy to use, and not restricted by the installation drop.

The cable is used for power frequency voltage U0/U6/6 (6/10), 8.7/10 (8.7/15), 12/20, 26/35 (26/45) kV power transmission and distribution system. -

Model, name and purpose

Model

Name

Scope of application

YJV

YJLV

Z(R)-YJV

Z(R)-YJLV

Copper core or aluminum core XLPE insulated and PVC sheathed power cable

Suitable for indoor and outdoor laying, where it can withstand a certain laying traction, but cannot withstand external mechanical forces. Single-core cables are not allowed to be laid in magnetic pipes

YJV22

YJLV22

Z(R)-YJV22

Z(R)-YJLV22

Copper core or aluminum core XLPE insulated PVC sheathed steel tape armored power cable

Suitable for buried laying, can withstand external mechanical forces, but cannot withstand large pulling forces

Note: Flame-retardant cables meet the burning test requirements of GB/T19666 and GB/T18380 or IEC60332-2. ZC means flame-retardant class C, ZB means flame-retardant class B, and ZA means flame-retardant class A.

Specifications

Model

Number of cores

Rated voltage U0/U (Um) kV

3.6/6

6/6 6/10

8.7/10

8.7/15

12/20

18/30

21/35

26/35

YJV

Z(R)-YJV

1

16-500

25-500

35-500

50-500

YJLV

Z(R)-YJLV

16-500

25-500

35-500

50-500

YJV

Z(R)-YJV

3

16-500

25-500

35-500

50-500

YJLV

Z(R)-YJLV

16-500

25-500

35-500

50-500

YJV22

Z(R)-YJV22

3

16-500

25-500

35-500

50-500

YJLV22

Z(R)-YJLV22

1. 1. U0-The rated voltage between the conductor used in the cable design and the metal shield or sheath;

Rated power frequency voltage between conductors for U-cable design;

Um-The maximum value of the highest system voltage that the device can withstand;

2. 2. U0 is divided into two categories according to the duration of the system ground fault, the specific categories are as follows:

Type 1 cables are used in systems where the single-phase ground fault time is generally not more than 1 mim each time, and can also be used in systems where the longest time is not more than 8h, and the cumulative annual time is not more than 125h.

Category 2 cables-used in systems with longer ground fault times and where higher requirements for cable insulation performance are required, Category 2 should also be adopted.

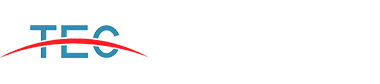

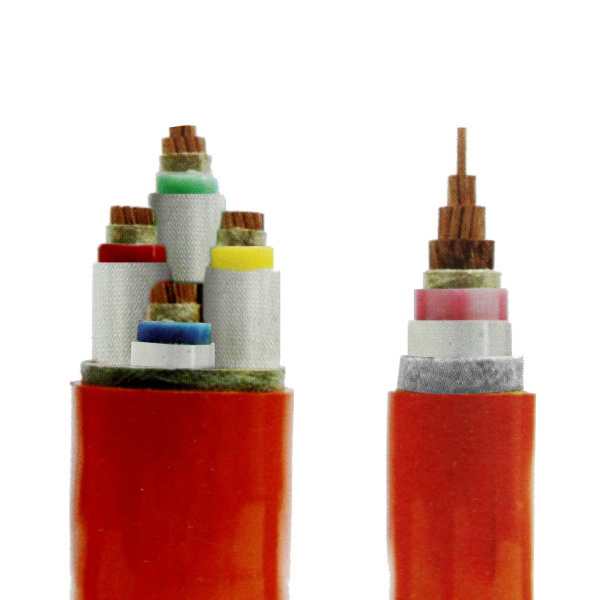

Typical structure description

1. 1. Conductor

The conductor part is composed of copper or aluminum and is tightly compressed and stranded by a nano-stretching die. It has the characteristics of smooth surface, good roundness, and large compaction coefficient.

2. 2. Semi-conductive shield

The semi-conductive materials of the conductor shielding and insulation shielding are all cross-linked, super smooth, and can adapt to three-layer co-extrusion.

3. 3. Insulation

The 35kV insulation material adopts imported ultra-purified cross-linked polyethylene material, and the purification level of the feeding system in the production process is 1000, which strictly guarantees the purification degree of the raw materials.

4. 4. Metal shield

Copper tape is used to meet the requirements of mechanical properties and short-circuit capacity.

5. 5. Inner sheath and filling

The filling is made of polypropylene tear film and the stranded filling rope, which can prevent the longitudinal penetration of water and increase the service life of the cable.

The inner sheath can be made of PVC plastic according to customer requirements; if the cable has waterproof requirements, the inner lining layer is made of extruded black linear low-density polyethylene.

6. 6. Armour layer

To meet the requirements of withstanding mechanical external forces during installation and laying, galvanized steel strips are used.

7. 7. Outer sheath

According to customer requirements, PVC and PE plastics can be used, and ordinary, flame-retardant, halogen-free and low-smoke, anti-termite, anti-rodent, weather-resistant, etc. can be provided. Its thickness is determined according to the outer diameter before extrusion or the international standard provided. -

1. 6-35kV cable core allows long-term maximum working temperature of 90℃.

2. The core short-circuit temperature shall not exceed 250℃, and the maximum duration shall not exceed 5 seconds.

3. Bending radius

Single core cable allowable bending radius: 20(d+D)±5%

Allowable bending radius of multi-core cable: 15(d+D)±5%

D-The actual outer diameter of the cable sample (mm),

d-The actual diameter of the conductor (mm).

4. Laying is not restricted by the horizontal drop.

5. Laying temperature

When laying below 0℃, it must be heated in advance. -

Cable structure parameters

3.6/6kV flame-retardant and non-flame-retardant single-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV YJLV

YJV

YJLV

Cu

AL

1*10

2.5

16.2

362

299

1.83

3.08

1*16

2.5

17.0

433

334

1.15

1.91

1*25

2.5

18.2

544

389

0.727

1.20

1*35

2.5

19.4

667

451

0.524

0.868

1*50

2.5

20.7

834.

524

0.387

0.641

1*70

2.5

22.6

1066

633

0.268

0.443

1*95

2.5

24.2

1330

742

0.193

0.320

1*120

2.5

25.8

1602

859

0.153

0.253

1*150

2.5

27.4

1911

982

0.124

0.206

1*185

2.5

29.2

2279

1134

0.0991

0.164

1*240

2.6

31.6

2838

1353

0.0754

0.125

1*300

2.8

34.4

3472

1615

0.0601

0.100

1*400

3.0

38.4

4516

2040

0.0470

0.0778

1*500

3.2

42.6

5592

2498

0.0366

0.0605

3.6/6kV flame-retardant and non-flame-retardant three-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV22

YJLV22

YJV

YJLV

YJV22

YJLV22

Cu

AL

3*10

2.5

31.0

35.4

1077

886

1809

1619

1.83

3.08

3*16

2.5

32.8

37.0

1314

1013

2070

1769

1.15

1.91

3*25

2.5

35.6

39.8

1678

1208

2496

2026

0.727

1.20

3*35

2.5

37.9

42.3

2066

1397

2946

2289

0.524

0.868

3*50

2.5

40.9

45.3

2599

1659

3558

2618

0.387

0.641

3*70

2.5

44.8

49.4

3321

2005

4393

3078

0.268

0.443

3*95

2.5

48.4

53.0

4175

2390

5332

3547

0.193

0.320

3*120

2.5

51.7

56.7

5015

2759

6301

4046

0.153

0.253

3*150

2.5

55.3

60.5

6016

3197

7420

4602

0.124

0.206

3*185

2.5

58.9

64.1

7158

3682

8654

5177

0.0991

0.164

3*240

2.6

64.5

70.0

8983

4473

10650

6140

0.0754

0.125

3*300

2.8

70.5

76.1

11007

5369

12863

7225

0.0601

0.100

3*400

3.0

78.9

86.1

14304

6787

17280

9762

0.0470

0.0778

3*500

3.2

87.0

94.8

17614

8217

18327

11629

0.0366

0.0605

6/6, 6/10kV flame-retardant and non-flame-retardant single-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV

YJLV

Cu

AL

1*16

3.4

18.8

494

395

1.15

1.91

1*25

3.4

20.2

618

463

0.727

1.20

1*35

3.4

21.2

735

519

0.524

0.868

1*50

3.4

22.7

917

607

0.387

0.641

1*70

3.4

24.4

1143

710

0.268

0.443

1*95

3.4

26.2

1425

837

0.193

0.320

1*120

3.4

27.6

1688

945

0.153

0.253

1*150

3.4

29.4

2016

1088

0.124

0.206

1*185

3.4

31.0

2375

1230

0.0991

0.164

1*240

3.4

33.4

2946

1460

0.0754

0.125

1*300

3.4

35.8

3563

1706

0.0601

0.100

1*400

3.4

39.2

4570

2094

0.0470

0.0778

1*500

3.4

42.8

5567

2472

0.0366

0.0605

6/6, 6/10kV flame-retardant and non-flame-retardant three-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV22

YJLV22

YJV

YJLV

YJV22

YJLV22

Cu

AL

3*16

3.4

36.9

41.3

1537

1236

2403

2103

1.15

1.91

3*25

3.4

39.7

44.3

1917

1447

2869

2399

0.727

1.20

3*35

3.4

42.0

46.4

2308

1650

3292

2634

0.524

0.868

3*50

3.4

45.0

49.8

2868

1928

3968

3029

0.387

0.641

3*70

3.4

48.9

53.9

3612

2296

4831

3515

0.268

0.443

3*95

3.4

52.7

57.5

4509

2724

5794

4009

0.193

0.320

3*120

3.4

55.9

60.9

5369

3113

6760

4504

0.153

0.253

3*150

3.4

59.6

64.6

6392

3573

7872

5053

0.124

0.206

3*185

3.4

63.2

68.4

7557

4080

9159

5682

0.0991

0.164

3*240

3.4

68.2

73.8

9343

4832

11137

6627

0.0754

0.125

3*300

3.4

73.3

79.1

11306

5668

13271

7633

0.0601

0.100

3*400

3.4

80.6

87.8

14500

6983

17540

10023

0.0470

0.0778

3*500

3.4

88.1

95.7

17760

8363

21166

11770

0.0366

0.0605

8.7/10, 8.7/15kV flame-retardant and non-flame-retardant single-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV

YJLV

Cu

AL

1*25

4.5

22.6

716

561

0.727

1.20

1*35

4.5

23.6

837

620

0.524

0.868

1*50

4.5

24.9

1012

703

0.387

0.641

1*70

4.5

26.8

1258

825

0.268

0.443

1*95

4.5

28.6

1546

958

0.193

0.320

1*120

4.5

30.0

1815

1072

0.153

0.253

1*150

4.5

31.8

2151

1222

0.124

0.206

1*185

4.5

33.4

2516

1371

0.0991

0.164

1*240

4.5

35.8

3096

1611

0.0754

0.125

1*300

4.5

38.2

3723

1866

0.0601

0.100

1*400

4.5

41.6

4743

2267

0.0470

0.0778

1*500

4.5

45.2

5789

2694

0.0366

0.0605

8.7/10, 8.7/15kV flame-retardant and non-flame-retardant three-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV22

YJLV22

YJV

YJLV

YJV22

YJLV22

Cu

AL

3*25

4.5

44.8

49.4

2256

1787

3329

2859

0.727

1.20

3*35

4.5

47.1

51.7

2664

2006

3791

3133

0.524

0.868

3*50

4.5

50.1

54.9

3246

2307

4470

3530

0.387

0.641

3*70

4.5

54.0

58.8

4018

2702

5334

4019

0.268

0.443

3*95

4.5

57.7

62.9

4919

3133

6381

4596

0.193

0.320

3*120

4.5

60.9

66.3

5800

3544

7374

5119

0.153

0.253

3*150

4.5

64.5

69.9

6848

4029

8515

5696

0.124

0.206

3*185

4.5

68.2

73.8

8037

4560

9832

6355

0.0991

0.164

3*240

4.5

73.3

79.1

9888

5378

11853

7343

0.0754

0.125

3*300

4.5

78.4

85.6

12889

6251

14849

9211

0.0601

0.100

3*400

4.5

85.7

93.1

15136

7619

18409

10892

0.0470

0.0778

3*500

4.5

93.2

101.8

18450

9053

22290

12894

0.0366

0.0605

12/20kV flame-retardant and non-flame-retardant single-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV

YJLV

铜Cu

铝AL

1*35

5.5

25.8

939

722

0.524

0.868

1*50

5.5

27.3

1132

823

0.387

0.641

1*70

5.5

29.0

1372

939

0.268

0.443

1*95

5.5

30.8

1667

1079

0.193

0.320

1*120

5.5

32.4

1957

1214

0.153

0.253

1*150

5.5

34.0

2283

1355

0.124

0.206

1*185

5.5

35.8

2671

1526

0.0991

0.164

1*240

5.5

38.2

3262

1776

0.0754

0.125

1*300

5.5

40.4

3879

2022

0.0601

0.100

1*400

5.5

43.8

4912

2436

0.0470

0.0778

1*500

5.5

47.4

5971

2876

0.0366

0.0605

12/20kV flame-retardant and non-flame-retardant three-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV22

YJLV22

YJV

YJLV

YJV22

YJLV22

Cu

AL

3*35

5.5

51.9

57.1

3026

2368

4343

3686

0.524

0.868

3*50

5.5

54.9

60.1

3628

2688

5020

4080

0.387

0.641

3*70

5.5

58.7

64.1

4425

3110

5944

4629

0.268

0.443

3*95

5.5

62.6

68.2

5377

3592

7025

5240

0.193

0.320

3*120

5.5

65.8

71.4

6281

4026

8012

5757

0.153

0.253

3*150

5.5

69.4

75.0

7355

4536

9181

6362

0.124

0.206

3*185

5.5

73.1

79.3

8570

5093

10602

7125

0.0991

0.164

3*240

5.5

78.2

84.4

10458

5948

12631

8121

0.0754

0.125

3*300

5.5

83.1

90.9

12459

6822

15721

10083

0.0601

0.100

3*400

5.5

90.6

98.6

15794

8277

19388

11871

0.0470

0.0778

3*500

5.5

98.1

106.5

19162

9765

23147

13575

0.0366

0.0605

18/30kV flame-retardant and non-flame-retardant single-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV

YJLV

Cu

AL

1*50

8.0

34.5

1552

1242

0.387

0.641

1*70

8.0

36.2

1812

1379

0.268

0.443

1*95

8.0

38.0

2130

1542

0.193

0.320

1*120

8.0

39.4

2420

1678

0.153

0.253

1*150

8.0

41.2

2785

1857

0.124

0.206

1*185

8.0

42.8

3175

2030

0.0991

0.164

1*240

8.0

45.2

3795

2309

0.0754

0.125

1*300

8.0

47.6

4461

2604

0.0601

0.100

1*400

8.0

51.0

5535

3059

0.0470

0.0778

1*500

8.0

54.6

6639

3544

0.0366

0.0605

21/35kV flame-retardant and non-flame-retardant single-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃)Ω/km

YJV

YJLV

YJV

YJLV

Cu

AL

1*50

9.3

37.1

1718

1408

0.387

0.641

1*70

9.3

38.8

1985

1551

0.268

0.443

1*95

9.3

40.6

2310

1722

0.193

0.320

1*120

9.3

42.0

2606

1864

0.153

0.253

1*150

9.3

43.8

2979

2050

0.124

0.206

1*185

9.3

45.4

3375

2230

0.0991

0.164

1*240

9.3

47.8

4005

2519

0.0754

0.125

1*300

9.3

50.2

4681

2824

0.0601

0.100

1*400

9.3

53.6

5769

3293

0.0470

0.0778

1*500

9.3

57.2

6889

3794

0.0366

0.0605

26/35kV flame-retardant and non-flame-retardant single-core XLPE insulated and PVC sheathed power cable

Nominal section mm²

Nominal thickness of insulation mm

Theoretical cable outer diameter mm

Theoretical weight kg/km

Maximum DC resistance of conductor (20℃) Ω/km

YJV

YJLV

YJV

YJLV

Cu

AL

1*50

10.5

39.7

1900

1590

0.387

0.641

1*70

10.5

41.4

2174

1740

0.268

0.443

1*95

10.5

43.2

2507

1919

0.193

0.320

1*120

10.5

44.6

2809

2067

0.153

0.253

1*150

10.5

46.4

3190

2261

0.124

0.206

1*185

10.5

48.0

3593

2448

0.0991

0.164

1*240

10.5

50.4

4233

2747

0.0754

0.125

1*300

10.5

52.8

4919

3062

0.0601

0.100

1*400

10.5

56.2

6022

3546

0.0470

0.0778

1*500

10.5

59.8

7158

4063

0.0366

0.0605

-

Delivery length

The delivery length of the cable should not be less than 100m, and the measurement error should not be greater than ±0.5%.

24 cores and below: It is allowed to deliver short cables with a length of not less than 20 meters, and the quantity should not exceed 5% of the total length of delivery.

More than 24 cores: It is allowed to deliver short cables with a length of not less than 20 meters, and the quantity should not exceed 10% of the total length of delivery.

According to the agreement between the two parties, any length of cable is allowed to be delivered.

Packaging signs and transportation

Cables in coils or coils should be neatly wound and properly packaged.

Each circle or plate should be attached with a label indicating:

Manufacturer name or trademark

Cable model and specification mm2

Rated voltage V

Length m

Manufacturing Date: Year Month

Standard number

Gross weight kg:

Correct rotation direction of the cable reel

Transport and storage

Spools are not allowed to lay flat

During transportation, it is strictly forbidden to lower the cable reel with cables from a high place, and it is strictly forbidden to lose the cables mechanically.

When hoisting packages, it is strictly forbidden to hoist several trays at the same time. On vehicles, ships and other transportation tools, the cable reel must be placed firmly and fixed with a suitable method to prevent mutual collision or overturning.

Previous

Next

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!