Flame-retardant wire and cable

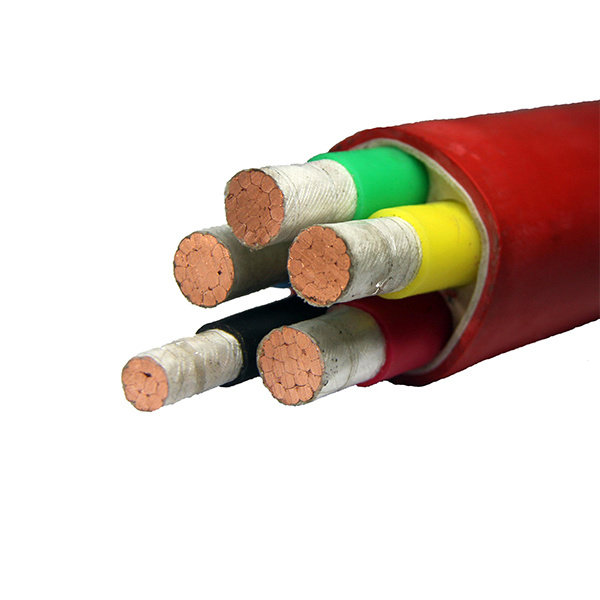

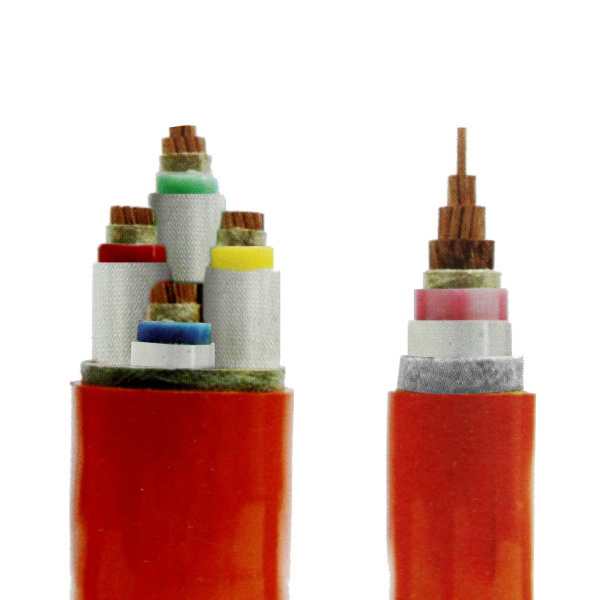

This product is suitable for transmission of electric energy in power lines with a rated voltage of 0.6/1KV and below. Resistant wires and cables are difficult to catch fire and have the ability to prevent or delay the spread of flames. They are suitable for laying in a variety of occasions where cables have flame-retardant requirements, such as high-rise buildings, hotels, hospitals, subways, nuclear power plants, power plants, mines, and petroleum. , Chemical industry, etc.

Classification:

Key words:

Flame-retardant wire and cable

- Description

- Model and specification

- Usage characteristics

- Parameter

- Transportation

-

- Commodity name: Flame-retardant wire and cable

- Commodity ID: 1329827697869344768

This product is suitable for transmission of electric energy in power lines with a rated voltage of 0.6/1KV and below. Resistant wires and cables are difficult to catch fire and have the ability to prevent or delay the spread of flames. They are suitable for laying in a variety of occasions where cables have flame-retardant requirements, such as high-rise buildings, hotels, hospitals, subways, nuclear power plants, power plants, mines, and petroleum. , Chemical industry, etc.

This product is suitable for power transmission in power lines with a rated voltage of 0.6/1KV and below. Resistant wire and cable have the ability to catch fire and prevent or delay the spread of flame. It is suitable for laying in a variety of occasions where the cable has flame-retardant requirements, such as high-rise buildings, hotels, hospitals, subways, nuclear power plants, power plants, mines, and petroleum. , Chemical industry, etc.

Product implementation standards:GB/T19666-2005, GB/T5023-2008, GB/T12706.1-2008, GB/T9330-2008Instructions for flame-retardant wires and cables

Flame-retardant wire and cable refers to being burned under the specified test conditions, so that the flame spread is only within a limited range. After the fire source is removed, the residual smoke and residual burn can extinguish the cable by itself within a limited time

Flame retardant grade of flame retardant wire and cable

The burning of finished wires and cables is divided into single burning test and bundle burning test.

Single burning test method: Take the vertical support of the specimen with the specified length, place the rubberized kraft paper "flame indicator" on the upper part of the specimen, and place the surgical cotton ball under the specimen. Use a blowtorch to supply fire to the specimen for 15s, Stop for 15s. After repeated 5 cycles, if the "flame indicator" burns more than 25%, the burning drops ignite the cotton ball, and the flame lasts for more than 60s, it will be judged as unqualified, otherwise it is qualified.

Bundle burning test method: The cables are arranged in a bundle on a vertical ladder frame, and the sample is supplied with a torch for a specified time from the bottom to the top. After stopping the fire supply for 1 hour, measure the height of the carbonized part of the sample. If the height of the carbonized part does not exceed 2.5 meters, it is judged as qualified, otherwise it is unqualified.

According to the test conditions specified in GB/T18380.3-2002, flame-retardant wires and cables are divided into four levels: A, B, C, and D

Table 1Flame retardant grade

Fire temperature

Fire time

The volume of non-metallic materials for laying cables in bundles

Charring height

Self-extinguishing time

Applicable products

A

≥815℃

40min

≥7L/m

≤2.5m

≤1h

Flame retardant cable

B

≥815℃

40min

≥3.5L/m

≤2.5m

≤1h

Flame retardant cable

C

≥815℃

20min

≥1.5L/m

≤2.5m

≤1h

Flame retardant cable

D

≥815℃

20min

≥0.5L/m

≤2.5m

≤1h

Flame retardant insulated wire

-

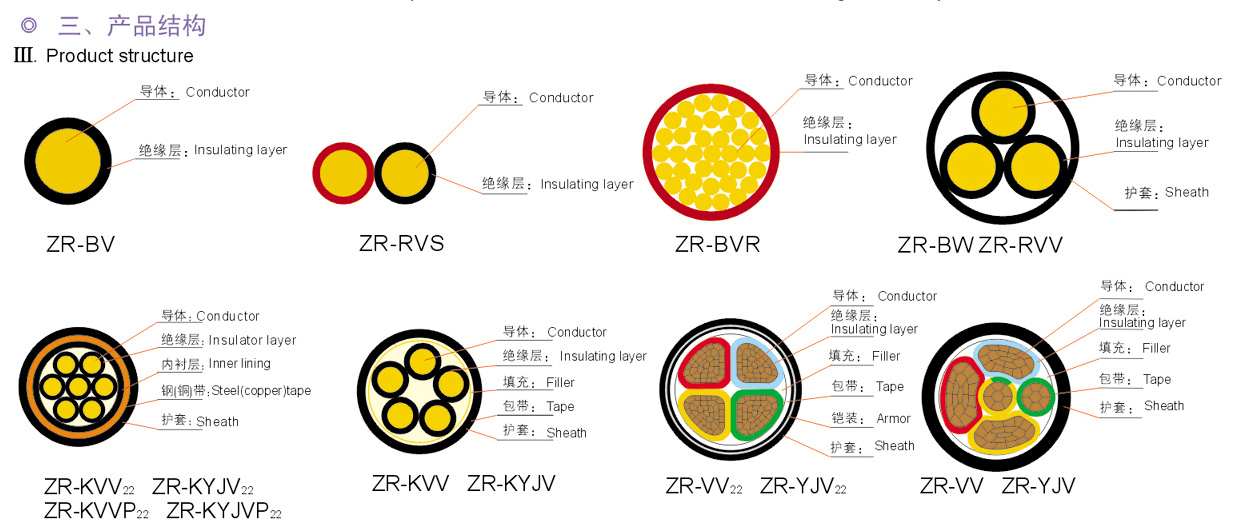

Representation of flame-retardant wire and cable products

The model representation method of the flame-retardant wire and cable: The model of the flame-retardant wire and cable is added ○-□ before the model of the ordinary cable. 〇- is the flame-retardant code and represented by Z, □- is the flame-retardant grade code, and the flame-retardant grade ABCD is used Means.

Products are expressed by model, rated voltage, core number, nominal cross section and the number of this standard.

For example: Rated voltage 450/750V flame-retardant PVC wire, single core, 4mm2, expressed as ZB-BV 450/750V 1*4 Q/TEC16.03-2005

Rated voltage 600/1000V flame-retardant Class B XLPE insulated PVC sheathed power cable, 3-core, 240mm2, denoted as ZB-YJV 600/1000V 3*240 Q/TEC16.03-2005See the table for the model and name of the cable

Model

Name

Flame retardant rating

Core number

Cross section

mm2Rated voltage

vZ-BV

PVC insulated flame retardant wire with copper core

A、B、C、D

1

1.5-400

450/750

Z -BVV

PVC insulated flame retardant round cable with copper core and sheath A、B、C、D

1-5

1.5-35

300/500

Z -BVVB

PVC insulated flame retardant flat cable with copper core and PVC sheath

A、B、C、D

2,3

0.75-10

300/500

Z -BVR

PVC insulated flame retardant flexible cable with copper core

A、B、C、D

1

2.5-70

450/750

Z -RVS

PVC insulated flame retardant stranded connecting flexible cable with copper core

A、B、C、D

1

0.75-2.5

300/300

Z -RV

Sheathless flame retardant flexible cable with copper core A、B、C、D

1

1.5-240

450/750

Z -KVV

PVC insulated flame retardant control cable with PVC sheath A、B、C、D

2-61

1-10

450/750

Z -KVV22

PVC insulated flame retardant control cable with PVC sheath and steel tape armoring

A、B、C、D

2-61

1-10

450/750

Z -KVVP2

PVC insulated flame retardant control cable with PVC sheath and copper tape shielding

A、B、C、D

2-61

1-10

450/750

Z -KVVP2-22

PVC insulated flame retardant control cable with PVC sheath, copper tape shielding and steel tape armoring

A、B、C、D

2-61

1-10

450/750

Z -KYJV

Crosslinked polyethylene insulated flame retardant control cable with PVC sheath A、B、C、D

2-61

1-10

450/750

Z -KYJV22

Crosslinked polyethylene insulated flame retardant control cable with PVC sheath and steel tape armoring

A、B、C、D

2-61

1-10

450/750

Z -KYJVP2

Crosslinked polyethylene insulated flame retardant control cable with PVC sheath and copper tape shielding

A、B、C、D

2-61

1-10

450/750

Z -KYJVP2-22

Crosslinked polyethylene insulated flame retardant control cable with PVC sheath, steel tape armoring and copper tape shielding

A、B、C、D

2-61

1-10

450/750

Z -VV

PVC insulated flame retardant cable with PVC sheath A、B、C、D

1-5

1.5-800

600/1000

Z -VV22

PVC insulated flame retardant cable with PVC sheath and steel tape armoring

A、B、C、D

1-5

1.5-400

600/1000

Z -YJV

Crosslinked polyethylene insulated flame retardant cable with PVC sheath

A、B、C、D

1-5

1.5-800

600/1000

Z -YJV22

Crosslinked polyethylene insulated flame retardant cable with PVC sheath and steel tape armoring

A、B、C、D

1-5

1.5-400

600/1000

-

This product is suitable for power transmission in power lines with a rated voltage of 0.6/1KV and below. The resistance wire and cable is difficult to catch fire and has the ability to prevent or delay the spread of flame. It is suitable for a variety of occasions where the cable has flame retardant requirements

Using features

The rated voltage U0/U of the flame-retardant cable is 0.6/1KV, the rated voltage U0/U of the flame-retardant control cable is 450/750V, and the rated voltage U0/U of the flame-retardant wire and cable is 450/750V and below.

The long-term allowable working temperature of PVC insulated cables does not exceed 70℃, and the long-term allowable working temperature of XLPE insulated cables does not exceed 90℃

The ambient temperature during installation should not be lower than 0°C.

Minimum bending radius during cable installation

The outer diameter (D) of the flame-retardant wire is less than 25mm, the allowable bending radius of the cable should not be less than 4D, the outer diameter (D) is 25mm and above, and the allowable bending radius of the cable should not be less than 6D.

Flame-retardant and fire-resistant control cables: cables without armor layers should be no less than 6 times the outer diameter of the cables, cables with armored or copper tape shielding structures should be no less than 12 times the outer diameter of the cables.

The minimum bending radius of flame-retardant and fire-resistant power cables is shown in Table 3Single core cable

Multi-core cable

Item Item

Unarmored

Armored

Unarmored

Armored

Minimum bending radius during installation

20D

15D

15D

12D

D-Outer diameter of the cable

Table 4 Nominal cross-section of neutral conductor of multi-core cable

Nominal cross section of main insulated core conductor /min2

Nominal cross section of neutral conductor /min2

3+1, 3+2, 4+1 core

3+1, 3+2, 4+1 Cores4, 5 cores

4. 5 Cores4

2.5

4

6

4

6

10

6

10

16

10

16

25

16

25

35

16

35

50

25

50

70

35

70

95

50

95

120

70

120

150

70

150

185

95

185

240

120

240

300

150

300

400

185

400

The conductive core of the single-core cable is round, and those of 16mm2 and above can be pressed tightly. For multi-core cables with a cross-section of 35mm2 and below, the core should be round, and those with a cross-section of 50mm2 and above should be fan-shaped, tile-shaped or semicircular. The fourth core (neutral core) in a four-core cable can be round or fan-shaped. The neutral wire of a five-core cable can be round or tile-shaped. Those with a diameter of 6mm2 and below are allowed to be composed of a single conductor, and those with a diameter of 10mm2 and above are composed of multiple single wires. The shaped conductor (sector, tile or semicircle) should be tightly pressed.

Main performance

The finished wire should be able to withstand 5 cycles of vertical burning test without transmitting flame. After the test, the continuous burning time of the sample should not exceed 1h. The finished cable should be subjected to a bundled cable burning test. After the test, the height of the scorched or affected part of the cable should not exceed 2.5m above the point of action of the flame.

The wire and cable should withstand the low-temperature winding test or low-temperature impact test at -15℃. After the test, there should be no visible cracks on the surface of the sample.

The insulation volume resistivity of the finished wire at 70℃ should be greater than 1*1010Ω/cm.

The finished flame-retardant and fire-resistant wire should be able to withstand the 2.5KV AC voltage test without breakdown in 5 minutes. The finished flame-retardant and fire-resistant control cable should be able to withstand the 3KV AC voltage test without breakdown in 5 minutes. The finished flame-retardant and fire-resistant power cable should be able to withstand the 3.5KV AC voltage test, and the flame-retardant and fire-resistant wire and cable should not be broken for 5 minutes. The flame-retardant and fire-resistant wire and cable are made of highly flame-retardant polyvinyl chloride plastic, and the oxygen index is greater than 30%. The cables are the same.

Cable specifications and reference dataThe specifications, structural dimensions and weight of the flame-retardant wire and cable products are according to the common type and similar products.

Selection points of flame-retardant cablesWhen wires and cables are laid in bundles, flame-retardant wires and cables should be used.

Method for selecting flame retardant grade of flame retardant cable:

Calculate the total volume of non-metallic materials of wires and cables according to Table 5 to Table 7, and then determine the flame retardant grade according to Table 1.

For cables laid in the same channel, cables of the same flame-retardant grade should be selected. Flame-retardant and non-flame-retardant cables should not be laid in the same channel. For cables laid in a box with a cover and a cable trench with a cover, if measures such as blocking and water blocking have been taken to prevent flame extension, the first-class flame-retardant requirement can be reduced. The flame-retardant cable must indicate the flame-retardant level. Those who indicate the level shall be regarded as C level. -

Table 5 Reference table for non-metallic content of 450/750V PVC insulated wires

Cross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/m1.5

3.4

0.0076

16

8

0.0342

95

17

0.1319

300

29.5

0.3831

2.5

4.2

0.0113

25

9.8

0.0504

120

19

0.1634

400

33.5

0.4810

4

4.8

0.0141

35

11

0.0600

150

21

0.1962

6

5.4

0.0169

50

13

0.0827

185

23.5

0.2485

10

6.8

0.0263

70

15

0.1066

240

26.5

0.3113

Table 6 Reference table for non-metallic content of 0.6/1KV PVC insulated unarmored cables

1 core

3 cores

(3+1) cores

Cross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/m1.5

5.8

0.0294

1.5

10.4

0.0878

2.5

6.2

0.0327

2.5

11.3

0.0975

2.5

11.9

0.1099

4

7.1

0.0416

4

13.2

0.1238

4

13.7

0.1369

6

7.6

0.0461

6

14.3

0.1372

6

15.2

0.1572

10

8.9

0.0576

10

17.0

0.1742

10

17.8

0.1957

16

9.6

0.0643

16

18.6

0.1961

16

20.0

0.2295

25

11.2

0.0830

25

22.5

0.2910

25

23.7

0.3181

35

12.2

0.0926

35

24.6

0.3203

35

25.5

0.3448

50

14.0

0.1161

50

25.3

0.3481

50

28.6

0.4166

70

15.8

0.1386

70

28.4

0.4069

70

32.3

0.4864

95

18.0

0.1753

95

32.4

0.5098

95

37.3

0.6298

120

19.4

0.1918

120

35.4

0.5745

120

40.5

0.7090

150

21.6

0.2343

150

39.0

0.6911

150

44.4

0.8489

185

23.8

0.2809

185

43.0

0.8230

185

49.7

1.0244

240

26.5

0.3323

240

48.8

1.0379

240

56.0

1.2635

300

31.3

0.4284

300

53.0

1.2344

300

62.2

1.5166

Continued Table 6

4 cores

5 cores

(4+1) cores

(3+2) cores

Cross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/m1.5

11.2

0.1012

1.5

12.0

0.1158

2.5

12.2

0.1128

2.5

13.1

0.1294

2.5

12.9

0.1099

2.5

13.3

0.1474

4

14.3

0.1456

4

15.5

0.1717

4

15.0

0.1369

4

15.0

0.1723

6

15.5

0.1646

6

16.9

0.1908

6

16.6

0.1572

6

16.3

0.1913

10

18.6

0.2066

10

20.3

0.2410

10

19.6

0.1957

10

18.9

0.2290

16

20.4

0.2329

16

22.4

0.2716

16

22.4

0.2295

16

22.0

0.2732

25

24.7

0.3356

25

27.1

0.3932

25

26.2

0.3181

25

25.4

0.3596

35

27.1

0.3712

35

30.0

0.4465

35

28.6

0.3448

35

27.0

0.3848

50

27.5

0.4222

50

31.6

0.5273

50

29.9

0.4166

50

28.5

0.4471

70

31.4

0.5068

70

36.0

0.6182

70

33.9

0.4864

70

32.3

0.5218

95

36.0

0.6375

95

41.4

0.7916

95

39.0

0.6298

95

36.8

0.6635

120

39.1

0.7153

120

44.4

0.8834

120

41.5

0.7090

120

39.5

0.7445

150

43.4

0.8806

150

49.1

1.0808

150

46.9

0.8489

150

44.2

0.9157

185

47.8

1.0480

185

54.8

1.3155

185

52.0

1.0244

185

49.0

1.0960

240

54.3

1.3174

240

61.8

1.6326

240

59.0

1.2635

240

55.6

1.3450

300

60.9

1.5883

300

1 core

3 cores

(3+1) cores

Cross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/m1.5

5.6

0.0265

1.5

10.0

0.0768

2.5

6.0

0.0296

2.5

10.8

0.0858

2.5

11.4

0.0993

4

6.5

0.0331

4

11.9

0.0964

4

12.5

0.1114

6

7.0

0.0370

6

13.0

0.1078

6

13.7

0.1248

10

8.3

0.0468

10

15.7

0.1398

10

16.4

0.1578

16

9.0

0.0525

16

17.4

0.1589

16

18.5

0.1871

25

10.6

0.0691

25

21.2

0.2441

25

22.3

0.2678

35

11.6

0.0774

35

23.4

0.2696

35

24.1

0.2907

50

13.2

0.0938

50

23.6

0.2730

50

25.9

0.3201

70

15.1

0.1145

70

27.0

0.3299

70

29.9

0.3958

95

16.8

0.1325

95

30.1

0.3827

95

33.8

0.4701

120

18.5

0.1559

120

33.5

0.4562

120

37.4

0.5610

150

20.6

0.1915

150

37.3

0.5727

150

41.2

0.6797

185

22.8

0.2308

185

41.3

0.6985

185

46.2

0.8274

240

25.4

0.2751

240

46.7

0.8649

240

51.9

1.0103

300

30.1

0.3551

300

50.3

0.9897

300

57.5

1.1943

Continuous table of table 74 cores

5 cores

(4+1) cores

(3+2) cores

Cross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/mCross section

mm2Diameter

mmNonmetal content

l/m1.5

10.7

0.0912

1.5

11.5

0.1042

2.5

11.7

0.1019

2.5

12.6

0.1166

2.5

12.4

0.1141

2.5

12.2

0.1116

4

12.8

0.1151

4

13.9

0.1354

4

13.6

0.1284

4

13.3

0.1255

6

14.0

0.1316

6

15.2

0.1513

6

15.0

0.1481

6

14.7

0.1450

10

17.2

0.1671

10

18.7

0.1935

10

18.0

0.1842

10

17.3

0.1786

16

19.0

0.1896

16

20.7

0.2194

16

20.7

0.2235

16

20.3

0.2221

25

23.2

0.2833

25

25.5

0.3300

25

24.6

0.3152

25

23.7

0.3004

35

25.6

0.3138

35

28.4

0.3761

35

26.8

0.3439

35

25.4

0.3219

50

26.2

0.3375

50

28.9

0.4069

50

26.6

0.3616

50

26.2

0.3442

70

30.5

0.4250

70

33.9

0.5098

70

31.1

0.4606

70

30.4

0.4238

95

34.4

0.4962

95

38.1

0.6016

95

48.1

0.5398

95

34.1

0.5136

120

38.0

0.5901

120

41.7

0.7114

120

54.1

0.6370

120

37.3

0.6097

150

42.3

0.7309

150

46.4

0.8879

150

61.7

0.8010

150

41.8

0.7331

185

46.9

0.8906

185

52.1

1.1009

185

48.1

0.8073

185

46.9

0.9085

240

53.1

1.0996

240

58.3

1.3172

240

54.1

0.9972

240

52.7

1.0924

300

59.4

1.3031

300

-

Delivery length

The delivery length of the cable should not be less than 100m, and the measurement error should not be greater than 0.5%. It is allowed to deliver short cables with a length of not less than 20 meters, and the quantity should not exceed 10% of the total length of delivery.

According to the agreement between the two parties, any length of cable is allowed to be delivered.

Packaging signs and transportation

The cable should be properly packaged on a cable reel for delivery. The length of the cable extension should not be less than 300mm, and the end should be reliably sealed with a cable jacket.

Each cable package should be accompanied by a product quality certificate. The certificate should be placed in an impermeable bag and fixed on the side of the cable reel.

Each outer cable tray should be marked:

Length m Manufacturing Date: Year Month

Standard number

Gross weight kg:

The symbol that indicates the correct rotation direction of the cable reel. Transport and storage

Reel does not allow flat

During transportation, it is strictly forbidden to lower the cable reel with cables from a high place, and it is strictly forbidden to lose the cables mechanically.

When hoisting packages, it is strictly forbidden to hoist several trays at the same time. On vehicles, ships and other transportation tools, the cable reel must be placed firmly and fixed with a suitable method to prevent mutual collision or overturning.

Previous

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!