Electric heating for hollow sucker rod of pumping unit

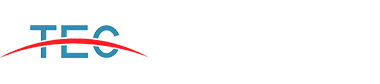

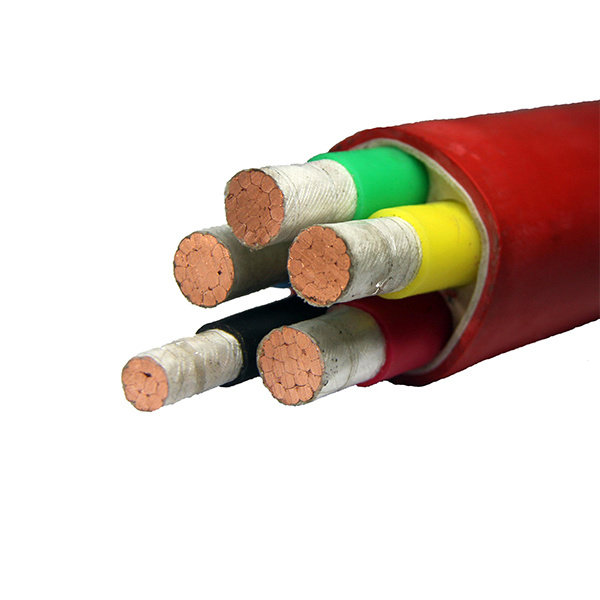

Metal MI heating cable, resistive heating, simple circuit system. It can be truly resistant to high temperatures (250-800°C), has high mechanical strength, compactness, smoothness, seamlessness, high application reliability, and long service life. It will really solve many technical problems of oil heating in oil wells. There are three application forms for electric heating of hollow-core sucker rods in oil wells: suitable for beam and belt pumping units 1. Heating within specified depth 2. To pump heating 3. Heating through the pump

Classification:

Key words:

Electric heating for hollow sucker rod of pumping unit

- Description

- Specification

- parameter

- output power

- Application

-

- Commodity name: Electric heating for hollow sucker rod of pumping unit

- Commodity ID: 1329827729360179200

Metal MI heating cable, resistive heating, simple circuit system. It can be truly resistant to high temperatures (250-800°C), has high mechanical strength, compactness, smoothness, seamlessness, high application reliability, and long service life. It will really solve many technical problems of oil heating in oil wells. There are three application forms for electric heating of hollow-core sucker rods in oil wells: suitable for beam and belt pumping units 1. Heating within specified depth 2. To pump heating 3. Heating through the pump

Metal MI heating cable, resistive heating, simple circuit system. It can be truly resistant to high temperatures (250-800°C), has high mechanical strength, compactness, smoothness, seamlessness, high application reliability, and long service life. It will really solve many technical problems of oil heating in oil wells.

There are three application forms for electric heating of hollow-core sucker rods in oil wells: suitable for beam and belt pumping units

1. Heating within specified depth

2. To pump heating

3. Heating through the pump

-

Select MI heating cable model:

Outer diameter mm, metal sheath type; heating cable surface heating strength w/cm2; sucker rod surface heating strength w/cm2 (should ensure that heavy oil does not coke)

Specifically, there are the following combined structure forms

Within 500m; two-core or three-core sheathed MI heating cable

Within 500m-1000m; combination of two or three single-core MI heating cables

Above 1000m; three single-core MI heating cables are combined, with 2~3 welded middle joints.

Temperature control:

The cold-end lead wire is a cold-resistant -50℃ soft cable, and the moving two ends have anti-bending pipe fittings.

The temperature electric control box is outdoor all-weather grade, non-explosion-proof, (should be placed in a safe area) to realize power transmission and temperature monitoring.

The temperature setting of the temperature controller can be set arbitrarily on site, and the upper and lower limit temperature of the test at the factory can be modified.

The temperature sensor is installed in the oil outlet pipe outside the nozzle, and the electric heating operation is automatically controlled according to the temperature at this point.

-

Technical solution description:

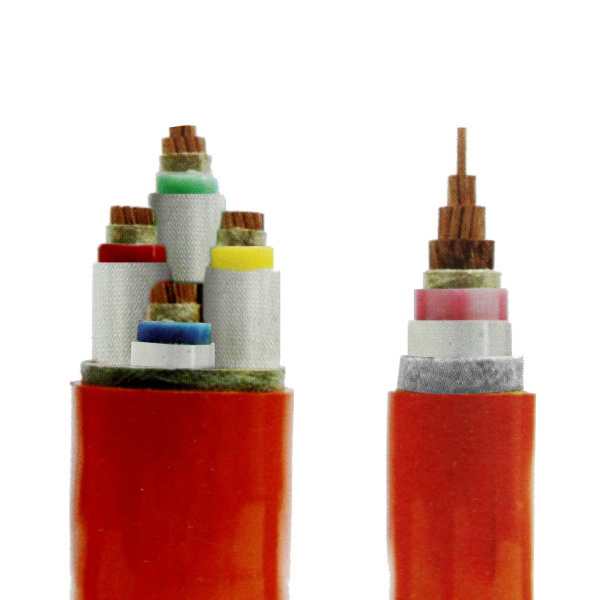

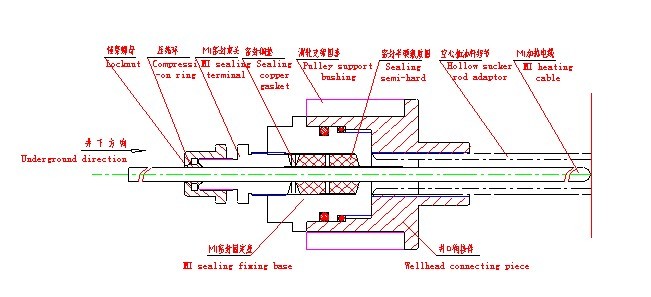

The electric heating system in the final hollow sucker rod is shown below

Figure 1. Schematic diagram of the heating device in the hollow sucker rod

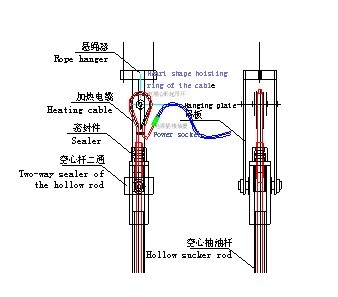

1. Variable buckle joint 2. Hollow sucker rod 3. Metal heating cable 4. Blowout preventer box 5. Polished rod 6. Two-way sealer 7. Oil pump

Basic calculation data: oilfield well number, well depth; casing diameter mm, tubing diameter mm; well calculation parameters: daily crude oil production; water cut percentage; set average well temperature + ℃, desired wellhead oil output temperature +℃; the inner diameter of the hollow sucker rod mm; the required length of the heating section in the well is m; the heating power of the well medium Kw; the heat dissipation power of the well casing Kw; the actual supplementary total heating power of the heating cable is Kw

-

General technical requirements for electric heating:

The lifting point requires the overall breaking force to be greater than 20000N; the inner diameter of the hollow sucker rod is 22mm, L=200—2000m;

Heating depth 200—2000m; Wellhead oil temperature 60--80℃; Heating power 30—150Kw;

Power supply voltage Three-phase 1140/660 VAC; 660/380VAC; or 380/220 VAC;

Principle:

Single-point suspension of the two-core or three-core metal heating cable into the hollow sucker rod to the required depth (or the top of the oil pump), pour the heat-conducting oil, and add a two-way type under the rope suspension The sealer completes the sealing and cold-to-heat conversion of the heating cable in the hollow rod. Utilizing the metal heating cable, the whole is compact and seamless, high temperature resistance, corrosion resistance, pure resistance heating and high thermal efficiency. The uniform heat generated by the mains voltage applied to the metal heating cable directly heats the hollow sucker rod, and the oil in the tubing is evenly heated by the hollow sucker rod.

-

Metal MI heating cable installation and operation process

1. Site preparation:

The approval document for wellhead construction has been issued;

The construction site is level and closed. Idlers cannot enter and meet HSE standard requirements;

The power supply connection point is completed;

Enter the security system;

All equipment arrived at the scene;

2. Construction preparation

Inventory and inspection of equipment and tools;

After the hollow sucker rod is installed. Combine and release a complete set of construction equipment for heating cables at the site, and place and anchor the turret on the metal heating cable reel.

Set up temporary scaffolding or operation platform ladder for wellhead.

Put the φ20mm steel ball head and steel cable slowly into the hollow sucker rod until the bottom of the hollow sucker rod. Make a mark on the exposed steel cable to prepare for measuring the total actual depth.

Use force and speed to lift and lower the steel ball head and steel cable in the hollow sucker rod, guarantee 2~3 times for each section, clean the channel and polish the burrs in the pipe.

Check the actual depth of the steel cable, check with the actual length of the heating cable supplied, and then check the other parameters of the heating cable.

The installation and connection parts of the hollow sucker rod installation sub-parts are normal, and there is no obvious leakage. The working position of the Christmas tree is normal.

3. Construction and installation

Check all installation parts and sealing materials.

Comprehensive linkage inspection of all operating instruments.

The person in charge of the construction site of the owner issues an order to start the formal construction operation.

Release the metal heating cable to the wellhead through the wellhead pulley, and thread all other parts at the end of the metal heating cable according to the sequence in Figure 3.

Install the wellhead connector.

Install the special accessories “MI seal holder” (pay attention to add O-ring seal).

Put in the sealed semi-hard fluorine rubber ring and the sealing copper gasket, and first tighten the MI seal head, and feel that the metal heating cable can still move up and down.

Check the linkage of the metal heating cable into the fixture of the installation tool and the cable reel.

Slowly feed the metal MI heating cable into the hollow sucker rod.

When the metal heating cable enters the tubing for about 100m, an operator must be guarded by the cable reel to prevent and prevent the metal heating cable from being dragged into the well, and the damping cable will continue to enter slowly under the control of external force.

When the entering metal MI heating cable body obviously releases its weight, it indicates that the design depth defined in the hollow sucker rod has been reached.

Tighten the MI seal beam head, compression ring, and lock nut in place.

Disassemble other installation aids, and complete the installation of the metal MI heating cable wellhead fixing assembly.

The final wellhead hollow sucker rod installation solid seal is shown above:

Connect the sealed metal power socket, and lay the cold power cable buried in the steel pipe into the temperature control box to prepare for power input.

Check again and there is no abnormality, the installation process is complete, you can ask the oil field technician to connect the rope suspension and enter the power transmission debugging stage.

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!