Electric heating belt for pipe welding

In response to the requirements of the pipeline welding process, the "Pipeline Welding Joint Electric Heating Belt" developed to meet the technical standard requirements. It can make the pipe weld joints rise rapidly in the short time allowed by the process preparation stage. After the pipe welding starts, the heating can continue to run simultaneously with the welding, and the heating will not affect all the welding process operations. Regardless of manual, semi-automatic, or automatic assembly line welding process, it can ensure the preheating of the welding port and the maintenance of the inter-layer temperature.

Classification:

Key words:

Electric heating belt for pipe welding

- Description

- Specification

- parameter

- output power

- Application

-

- Commodity name: Electric heating belt for pipe welding

- Commodity ID: 1329827733579649024

In response to the requirements of the pipeline welding process, the "Pipeline Welding Joint Electric Heating Belt" developed to meet the technical standard requirements. It can make the pipe weld joints rise rapidly in the short time allowed by the process preparation stage. After the pipe welding starts, the heating can continue to run simultaneously with the welding, and the heating will not affect all the welding process operations. Regardless of manual, semi-automatic, or automatic assembly line welding process, it can ensure the preheating of the welding port and the maintenance of the inter-layer temperature.

In the construction of modern transportation pipelines, in order to ensure pipeline pressure and save pipeline steel consumption, high-strength low-alloy steel materials are used to reduce the wall thickness of steel pipes. For example, X70 and X80 alloy steel pipes are used in the West-East Gas Pipeline Project.

The use of alloy steel pipe in engineering puts forward higher requirements on the welding process of the pipeline. When the pipe starts root welding, regardless of the ambient temperature, the starting temperature of the welded joint is required to reach +100°C, and the temperature during the filling and cap welding process is required to be above +80°C. This requires preheating of the welding joint before welding; during the welding process, it is required to maintain the temperature of the welding joint to ensure welding quality.

According to the requirements of pipeline welding process, we developed the "pipeline welding joint electric heating belt" to meet this technical standard requirement. It can make the pipe weld joints rise rapidly in the short time allowed by the process preparation stage. After the pipe welding starts, the heating can continue to run simultaneously with the welding, and the heating will not affect all the welding process operations. Regardless of manual, semi-automatic, or automatic assembly line welding process, it can ensure the preheating of the welding port and the maintenance of the inter-layer temperature.

-

Technical characteristics and model naming

1. Technical features

Easy operation and use: The welding port electric heating belt has a small, compact and strong structure, high surface heating strength, high use temperature, and meets the conditions of field construction; one operation can be simple and convenient to install, and it is in the welding process. Can be used continuously.

The temperature rises quickly, and the welding quality is guaranteed: within 20 minutes, the pipe weld edge can be heated up Δt≥80℃, (reference pipe diameter Ф1016, wall thickness 14.6 mm). Preheating does not affect normal mechanical counterpart operations. The welding joint temperature reaches the standard, so that the construction and supervision units can be assured of the welding quality. Heating does not affect pipeline welding; welding and welding bead repair operations also do not affect heating. There is no crossover of processes, and work efficiency is improved. (On average, 5 more crossings can be welded a day)

High temperature corrosion resistance: The welding port is electrically heated with a flexible stainless steel shell, which resists the splash and burning of the arc and welding slag during the welding process.

Energy saving and cost saving: The welding port electric heating belt is a pure resistive load. The welding generator installed in the field can be matched with the inductive load to improve the power factor of the generator, increase the output, and make full use of the field welding generator. The rich backup power, so there is no need to increase energy and costs.

Safe and reliable: The complete set of products has high electrical insulation strength, is equipped with a dedicated grounding wire, and has a leakage protection switch to ensure the safety of users.

Easy to maintain: There is basically no maintenance workload for the welding port electric heating belt under normal and correct use. When not in use, like other mobile electrical appliances, it needs to be cooled and placed in a dry place to avoid accidental squeezing, bumping, or impact. Once the insulation layer absorbs water and becomes damp, it can be energized for self-drying before normal use.

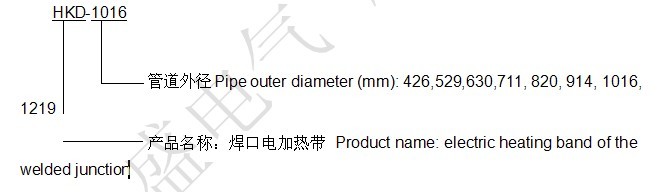

2. Model naming

The naming of the product consists of two parts: "product name" and applicable "pipe outer diameter", with an interval of "-" in the middle.

-

Main technical parameters

Model

Rated voltage

(V)

Rated power

(W)

Outline dimension (mm) (Lx WxH)

Reference weight

(kg)

Applicable pipe size

(mm)

HKD-1219

380/220

10500

3820×65×32

8

1219

HKD-1016

380/220

9000

3165×65×32

7

1016

HKD-914

380/220

7200

2900×65×32

6.5

914

HKD-820

380/220

6000

2600×65×32

6

820

HKD-711

380/220

4800

2260×65×32

5.5

711

HKD-630

380

4200

2010×65×32

5.3

630

HKD-529

380

3900

1690×65×32

5

529

HKD-426

220

3300

1370×65×32

4.8

426

HKD-355

220

2300

1285×65×32

2.9

355

-

Product structure and completeness

1. Product structure

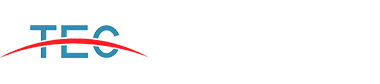

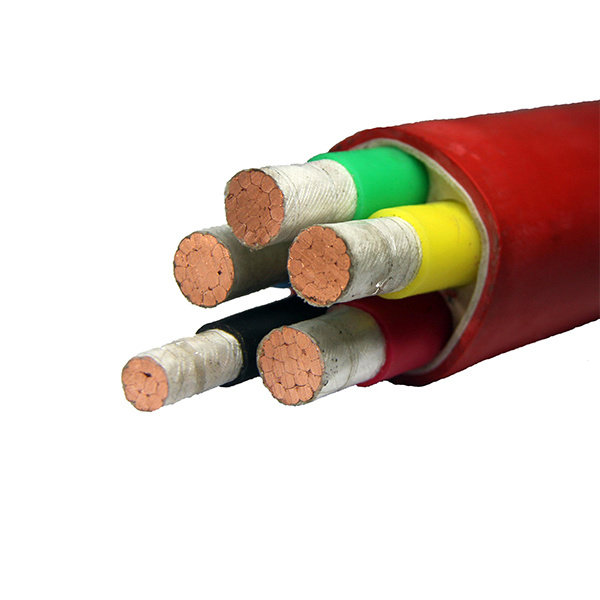

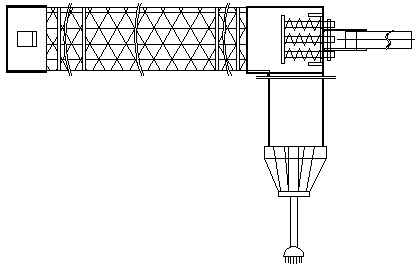

The welding port electric heating belt adopts stainless steel as its main structural frame, MI heating cable with stainless steel sheath as heating element, and high temperature resistant reinforced aluminum silicate fiber rope as inner insulation material. The outer protection has a flexible stainless steel shell. In the working process of the welding port electric heating belt, an energy storage spring can stably absorb the thermal elongation generated. Mounting hasp that can be locked tightly.

fast-install safe self-locking power socket. The installation thread of the temperature sensing element to facilitate automatic temperature control. Rubber sheathed cable with cold-resistant temperature of -20℃.

2. Product completeness

According to the actual on-site usage and the requirements of the welding process, we use two welding port electric heating belts and a set of circuit protection control boxes (optionally with automatic temperature control) for a welding joint design to form a set of welding joints heating equipment.

-

Installation

1. Before installation

A. Check the electrical insulation with a megger.

B. Clean the heating surface of the pipe to be dry and free of debris.

2. Installation and operation

A. Wrap the heating belt in the circumferential direction of the pipe. The inner side of the heating belt (the side without power lead) is placed 35mm from the pipe weld edge, and the two symmetrical heating belt fastening buckles are respectively located on the pipe section At the 10 o'clock and 2 o'clock positions (you can adjust this after the counterpart operation), it is better not to affect the operation of the welders at the stations on both sides of the pipeline. Press the spring lock device of the heating belt to make the electric heating belt close to the surface of the pipe to facilitate the transfer of heat and improve the heating efficiency.

B. Wrap the heat preservation quilt (reservation from the factory) on the heating nozzle.

C. Plug in the power plug and turn on the electric heating belt switch of the welding port to heat up. Please note: When moving the pipeline in the counterpart operation, someone should hold the power cable of the welding port electric heating belt to prevent the vibration of the external mechanical force from damaging the welding port electric heating belt.

D. After the welding joint temperature reaches the technological requirement (+100℃), remove the heat preservation quilt and start the first root welding operation.

E. During the second pass of welding until the last pass of cap welding:

Ⅰ) When the root welding unit is displaced, first turn off the switch, unplug all sockets, and cut off the power supply of the welding port electric heating belt.

Ⅱ) When the filler welding unit is in place, plug in all the power plugs, turn on the switch, and the two welding port electric heating belts continue to heat up. When the units are shifted sequentially in the future, the analogy is in turn.

Please note: 1. The socket cannot be used as an operating switch in accordance with electrical specifications! 2. Do not damage the outer protective stainless steel metal shell of the reinforced aluminum silicate fiber rope when grinding and repairing the weld bead! 3. The socket body must be grasped for natural locking or unlocking operations, and it is strictly forbidden to pull the cable body to operate with force! 4. It is strictly forbidden to ignite the electric welding head of the welded pipe on the heating belt or lap the electric welding floor on the metal body of the electric heating belt.

Ⅲ) If the temperature of the pipe weld is too high, you can turn off the 1~6 switches of the two heating bands one by one to cut off the grouping power supply in the heating band. On the contrary, if the temperature drops, the switch that has been turned off can be restored, and the group power supply in the heating zone can be reconnected. (If an automatic temperature controller is used, there is no such operation)

Ⅳ) If the unit shifts and connects for a long time, you can add heat preservation to the weld joint again.

Next

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!