Special purpose MI cable

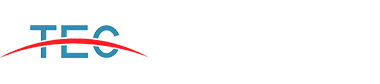

This series of products take advantage of the high temperature resistance, radiation resistance, corrosion resistance, and high mechanical strength of the mineral insulated cable's all-inorganic material structure. Through the reasonable selection of structural materials, the maximum operating temperature can reach 1000 ℃. Long-term operation in harsh environments where conventional organic insulated cables cannot be used, such as strong corrosion, and in the active area of nuclear reactors. According to its application areas, product types include: The high-temperature lead-out cable of automobile sensors has a maximum continuous operating temperature of 900°C and a short-term operating temperature of 950°C. It is used to transmit various signals detected by the automobile internal combustion engine high-temperature exhaust gas sensor from the internal high-temperature area to the external area; The core instrument system mineral insulated cable can withstand the highest temperature up to 900°C. It can still maintain good electrical performance when the cumulative γ radiation dose reaches 2x106Gy. It can be used for the transmission of various detection and control signals in the nuclear power plant core instrument system. , Ignition of hydrogen accumulation on the top of the shell and detection of neutron quantity; Forced cooling type hollow conductor mineral insulated cable, the highest operating temperature can reach 1000 ℃, coolant (such as inert gas, pure water, liquid nitrogen, etc.) can be passed into the conductor for forced cooling, so that the current carrying capacity of the cable can be increased by several orders of magnitude ; Mineral insulated cables for other high temperature, high pressure, and strong corrosive occasions, such as signal and power transmission cables for special applications where conventional cables such as metallurgy, kilns, and chemicals cannot meet the requirements of use. The above-mentioned products have obtained 5 invention patent authorizations and 8 utility model patent authorizations, among which the invention patents are: (1) Triaxial mineral insulated cable and its manufacturing method, patent number ZL200910154574.3 (2) Double-shielded mineral insulated cable and its manufacturing method, patent number ZL200910153535.1 (3) High temperature and radiation resistant inorganic insulating hollow cable and its manufacturing method and mold, patent number ZL201010582571.2 (4) A hydrogen igniter for nuclear power, patent number ZL201410165118.X (5) A high temperature and radiation resistant signal transmission cable for nuclear power and its manufacturing method, patent number ZL201610544584.8 To To Automotive sensor high temperature lead cable It is composed of conductor, mineral powder insulation layer and metal sheath. The maximum length of a single wire can be up to 400m, and it can be supplied in fixed lengths according to your needs. The structural materials are as follows: ——Conductor: nickel-chromium alloy, Inconel 600, pure nickel, 310S or 310H; ——Insulation: high-purity magnesium oxide powder (MgO), aluminum oxide powder (Al2O3) or silicon oxide powder (SiO2); -Sheath: 304L, 321, 316L, 310S, 310H, Inconel 600 or 825 alloy. Core instrument system mineral insulated cable According to the function of the product, it is divided into nuclear mineral insulated control cables, nuclear mineral insulated signal cables, nuclear hydrogen igniters and neutron detectors. Nuclear mineral insulated control cable It is used for the temperature, pressure, valve position signal transmission and neutron detection of the core instrument system, as well as the power transmission and control signal transmission of pumps, valves and other electrical equipment. It is composed of a conductor, a mineral powder insulation layer and a metal sheath. The conductor can be a single-grade metal conductor, a thermocouple wire with K graduation or a combination thereof. The structural materials are as follows: ——Conductor: copper, nickel-chromium alloy, pure nickel, K graduation thermocouple conductor (nickel-chromium-nickel aluminum or nickel-chromium-nickel silicon) ——Insulation: high-purity magnesium oxide powder (MgO), aluminum oxide powder (Al2O3) or silicon oxide powder (SiO2); -Sheath: 304L, 321, 316L, Inconel 600 or 825 alloy. Mineral insulated signal cables for nuclear use It is used for the transmission of high-frequency signals in the core instrument system. It is a single-core coaxial structure. According to different requirements for signal transmission anti-interference performance, there are three structures: coaxial, double shielded and triaxial: ——Mineral insulated coaxial cable: consists of conductor, mineral powder insulation and metal sheath from the inside to the outside; ——Mineral insulated double-shielded cable: It is composed of conductor, mineral powder inner insulating layer, inner shielding layer, mineral powder outer insulatin

Classification:

Key words:

Special purpose MI cable

- Description

- structure

- parameter

- Laying and installation

- Application area

-

- Commodity name: Special purpose MI cable

- Commodity ID: 1329827736461135872

This series of products take advantage of the high temperature resistance, radiation resistance, corrosion resistance, and high mechanical strength of the mineral insulated cable's all-inorganic material structure. Through the reasonable selection of structural materials, the maximum operating temperature can reach 1000 ℃. Long-term operation in harsh environments where conventional organic insulated cables cannot be used, such as strong corrosion, and in the active area of nuclear reactors. According to its application areas, product types include: The high-temperature lead-out cable of automobile sensors has a maximum continuous operating temperature of 900°C and a short-term operating temperature of 950°C. It is used to transmit various signals detected by the automobile internal combustion engine high-temperature exhaust gas sensor from the internal high-temperature area to the external area; The core instrument system mineral insulated cable can withstand the highest temperature up to 900°C. It can still maintain good electrical performance when the cumulative γ radiation dose reaches 2x106Gy. It can be used for the transmission of various detection and control signals in the nuclear power plant core instrument system. , Ignition of hydrogen accumulation on the top of the shell and detection of neutron quantity; Forced cooling type hollow conductor mineral insulated cable, the highest operating temperature can reach 1000 ℃, coolant (such as inert gas, pure water, liquid nitrogen, etc.) can be passed into the conductor for forced cooling, so that the current carrying capacity of the cable can be increased by several orders of magnitude ; Mineral insulated cables for other high temperature, high pressure, and strong corrosive occasions, such as signal and power transmission cables for special applications where conventional cables such as metallurgy, kilns, and chemicals cannot meet the requirements of use. The above-mentioned products have obtained 5 invention patent authorizations and 8 utility model patent authorizations, among which the invention patents are: (1) Triaxial mineral insulated cable and its manufacturing method, patent number ZL200910154574.3 (2) Double-shielded mineral insulated cable and its manufacturing method, patent number ZL200910153535.1 (3) High temperature and radiation resistant inorganic insulating hollow cable and its manufacturing method and mold, patent number ZL201010582571.2 (4) A hydrogen igniter for nuclear power, patent number ZL201410165118.X (5) A high temperature and radiation resistant signal transmission cable for nuclear power and its manufacturing method, patent number ZL201610544584.8 To To Automotive sensor high temperature lead cable It is composed of conductor, mineral powder insulation layer and metal sheath. The maximum length of a single wire can be up to 400m, and it can be supplied in fixed lengths according to your needs. The structural materials are as follows: ——Conductor: nickel-chromium alloy, Inconel 600, pure nickel, 310S or 310H; ——Insulation: high-purity magnesium oxide powder (MgO), aluminum oxide powder (Al2O3) or silicon oxide powder (SiO2); -Sheath: 304L, 321, 316L, 310S, 310H, Inconel 600 or 825 alloy. Core instrument system mineral insulated cable According to the function of the product, it is divided into nuclear mineral insulated control cables, nuclear mineral insulated signal cables, nuclear hydrogen igniters and neutron detectors. Nuclear mineral insulated control cable It is used for the temperature, pressure, valve position signal transmission and neutron detection of the core instrument system, as well as the power transmission and control signal transmission of pumps, valves and other electrical equipment. It is composed of a conductor, a mineral powder insulation layer and a metal sheath. The conductor can be a single-grade metal conductor, a thermocouple wire with K graduation or a combination thereof. The structural materials are as follows: ——Conductor: copper, nickel-chromium alloy, pure nickel, K graduation thermocouple conductor (nickel-chromium-nickel aluminum or nickel-chromium-nickel silicon) ——Insulation: high-purity magnesium oxide powder (MgO), aluminum oxide powder (Al2O3) or silicon oxide powder (SiO2); -Sheath: 304L, 321, 316L, Inconel 600 or 825 alloy. Mineral insulated signal cables for nuclear use It is used for the transmission of high-frequency signals in the core instrument system. It is a single-core coaxial structure. According to different requirements for signal transmission anti-interference performance, there are three structures: coaxial, double shielded and triaxial: ——Mineral insulated coaxial cable: consists of conductor, mineral powder insulation and metal sheath from the inside to the outside; ——Mineral insulated double-shielded cable: It is composed of conductor, mineral powder inner insulating layer, inner shielding layer, mineral powder outer insulatin

This series of products take advantage of the high temperature resistance, radiation resistance, corrosion resistance, and high mechanical strength of the all-inorganic material structure of the mineral insulated cable. Through the reasonable selection of structural materials, the maximum operating temperature can reach 1000 ℃. Long-term operation in harsh environments where conventional organic insulated cables cannot be used, such as high temperature, high pressure, and strong corrosion, and in the active area of nuclear reactors.

According to its application areas, product types include:

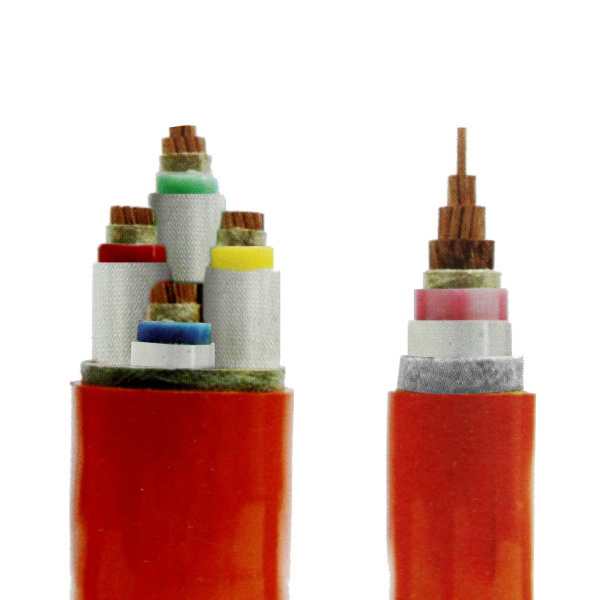

The high-temperature lead-out cable for automotive sensors has a maximum continuous operating temperature of 900℃ and a short-term operating temperature of 950℃. It is used to transmit various signals detected by the automotive internal combustion engine high-temperature exhaust gas sensor from the internal high-temperature area to the external area;

The mineral insulated cable of the core instrument system can withstand the highest temperature up to 900℃, and it can still maintain good electrical performance when the cumulative γ radiation dose reaches 2x106Gy, and can be used in nuclear power plants Transmission of various detection and control signals in the core instrument system, ignition of hydrogen accumulation on the top of the shell, and detection of neutron quantity;

Forced cooling type hollow conductor mineral insulated cable, the maximum operating temperature can reach 1000 ℃, coolant (such as inert gas, pure water, liquid nitrogen, etc.) can be passed into the conductor for forced cooling, so that the current carrying capacity of the cable can be increased Several orders of magnitude;

Other high-temperature, high-pressure, and strong-corrosion applications use mineral insulated cables, such as signal and power transmission cables for special applications where metallurgy, kiln, chemical and other conventional cables cannot meet the requirements of use.

The above products have obtained 5 invention patent authorizations and 8 utility model patent authorizations, among which the invention patents are:

(1) Triaxial mineral insulated cable and its manufacturing method, patent number ZL200910154574.3

(2) Double-shielded mineral insulated cable and its manufacturing method, patent number ZL200910153535.1

(3) High temperature and radiation resistant inorganic insulating hollow cable and its manufacturing method and mold, patent number ZL201010582571.2

(4) A hydrogen igniter for nuclear power, patent number ZL201410165118.X

(5) A high temperature and radiation resistant signal transmission cable for nuclear power and its manufacturing method, patent number ZL201610544584.8

-

Automobile sensor high temperature lead-out cable

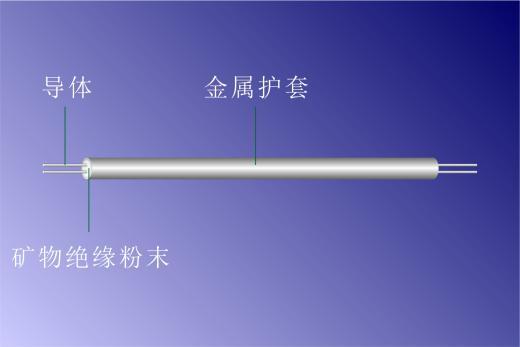

Consisting of conductor, mineral powder insulation layer and metal sheath, the maximum length of a single wire can be up to 400m, and it can be supplied in fixed lengths according to your needs. The structural materials are as follows:

——Conductor: nickel-chromium alloy, Inconel 600, pure nickel, 310S or 310H;

——Insulation: high-purity magnesium oxide powder (MgO), alumina powder (Al2O3) or silica powder (SiO 2);

—— Sheath: 304L, 321, 316L, 310S, 310H, Inconel 600 or 825 alloy.

Mineral insulated cable for core instrument system

According to the function of the product, it is divided into nuclear mineral insulated control cables, nuclear mineral insulated signal cables, nuclear hydrogen igniters and neutron detectors.

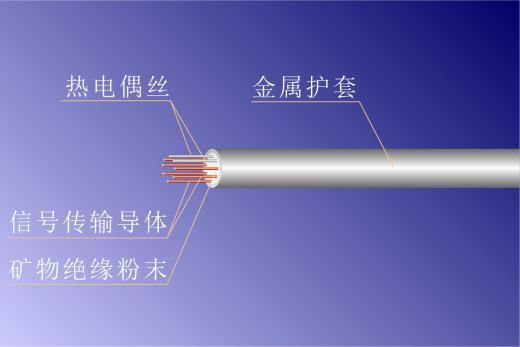

Nuclear mineral insulated control cable

It is used for the temperature, pressure, valve position signal transmission and neutron detection of the core instrument system, as well as the power transmission and control signal transmission of pumps, valves and other electrical equipment.

Consists of a conductor, a mineral powder insulation layer and a metal sheath. The conductor can be a single-grade metal conductor, K-indexed thermocouple wire or a combination thereof. The structural materials are as follows:

——Conductor: copper, nickel-chromium alloy, pure nickel, K-graded thermocouple conductor (nickel-chromium-nickel aluminum or nickel-chromium-nickel silicon)

——Insulation: high-purity magnesium oxide powder (MgO), alumina powder (Al2O3) or silica powder (SiO 2);

—— Sheath: 304L, 321, 316L, Inconel 600 or 825 alloy.

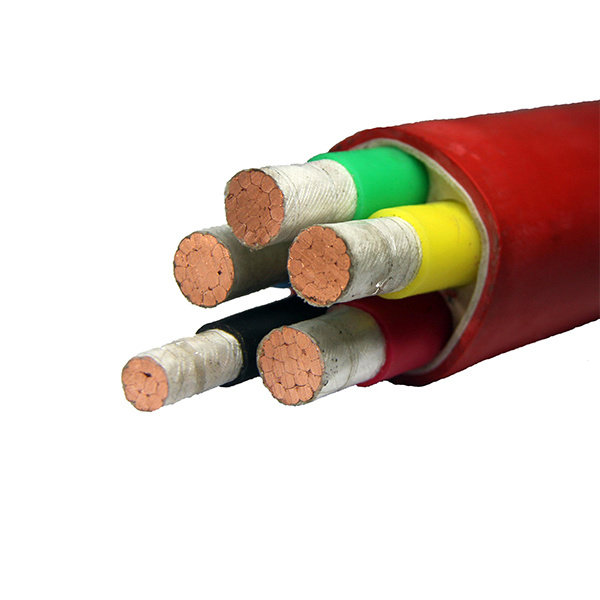

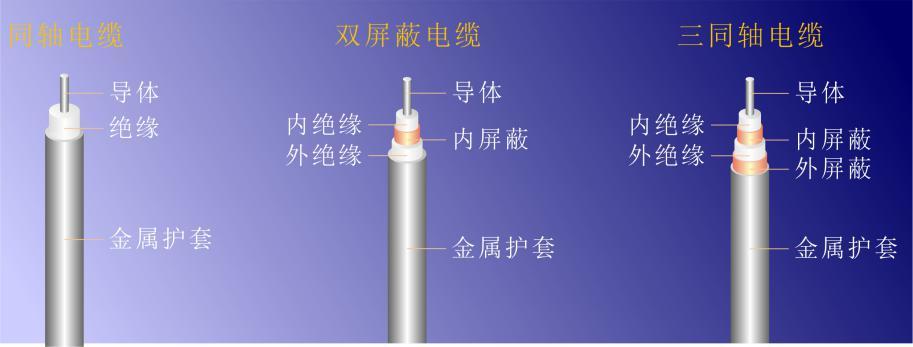

Nuclear mineral insulated signal cable

It is used for the transmission of medium and high-frequency signals in the core instrument system. It is a single-core coaxial structure. According to different requirements for signal transmission anti-interference performance, there are three structures: coaxial, double shielded and triaxial:

——Mineral insulated coaxial cable: consists of conductor, mineral powder insulation and metal sheath from the inside to the outside;

——Mineral insulated double-shielded cable: consists of conductor, mineral powder inner insulation layer, inner shielding layer, mineral powder outer insulation layer and metal sheath from the inside to the outside;

——Mineral insulated triaxial cable: It is composed of conductor, mineral powder inner insulating layer, inner shielding layer, mineral powder outer insulating layer, outer shielding layer and metal sheath from inside to outside.

The constituent materials are as follows:

——Conductor: copper, nickel-chromium alloy or pure nickel

——Internal insulation/external insulation: high-purity magnesium oxide powder (MgO), alumina powder (Al2O3) or silica powder ( SiO2);

——Inner shield/Outer shield: copper, 304L, 321, 316L, Inconel 600 or 825 alloy;

—— Sheath: 304L, 321, 316L, Inconel 600 or 825 alloy.

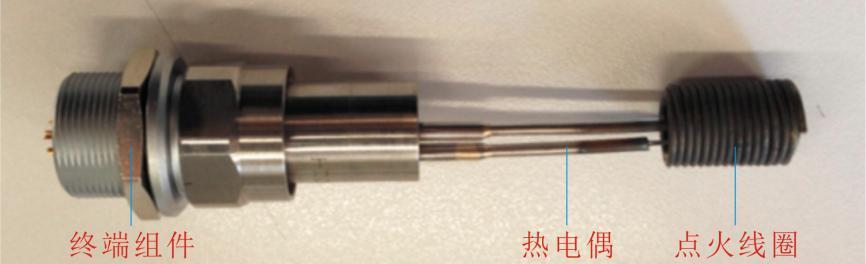

Nuclear hydrogen igniter

When the hydrogen produced in the containment of a nuclear power plant is still within the safe range in the event of a serious accident, it is used to implement active hydrogen ignition to slow the combustion of the hydrogen, thereby reducing the total amount of hydrogen in the containment and reducing the total amount of hydrogen in the containment. The concentration is kept below the flammable limit to avoid more serious hydrogen explosion accidents.

The product is composed of ignition coil, K-division thermocouple and terminal components. The ignition coil is made of high-temperature resistant nickel-based alloy sheathed mineral insulated cables. The conductor material is nickel-chromium alloy. The sheath material is 310 stainless steel, Inconel 600 or 825 alloy and other materials to choose from.

Neutron detector

Used to measure the core power distribution of the reactor, and output a current signal proportional to the core neutron flux.

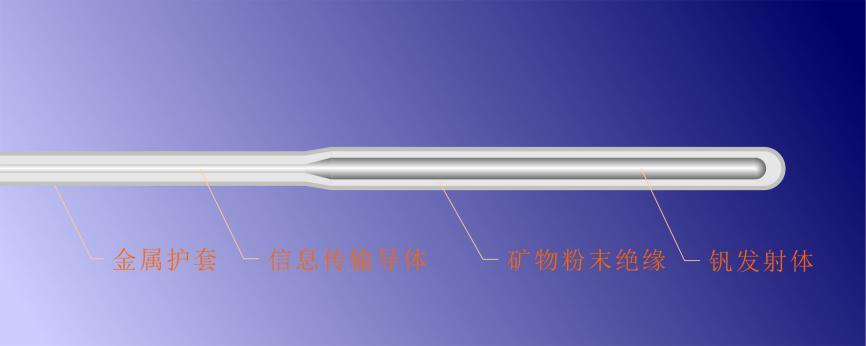

The product consists of a continuous metal sheath, signal core wire, vanadium emitter and mineral powder insulation material. The insulating material between the vanadium emitter and the signal line and the metal sheath is usually aluminum oxide powder (Al2O3).

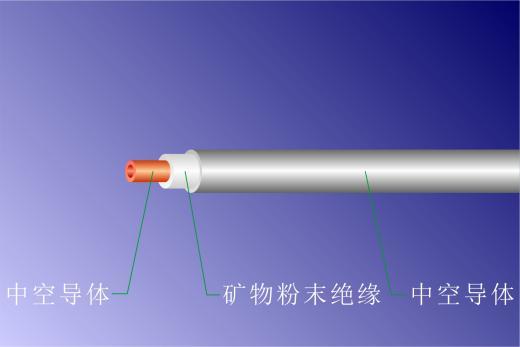

Forced cooling type hollow conductor mineral insulated cable

Consists of conductor, mineral powder insulation layer and metal sheath. The center of the conductor has an axial through hole for the circulation of coolant.

The structural materials are as follows:

——Conductor: copper or chromium-zirconium-copper alloy;

——Insulation: Magnesium Oxide (MgO);

—— Sheath: 304L, 321, 316L, 316LN, Inconel 600 or 825 alloy.

Mineral insulated cables for other high temperature, high pressure and strong corrosion occasions

Consists of conductor, mineral powder insulation layer and metal sheath. The structural materials are as follows:

——Conductor: copper, nickel-chromium alloy or pure nickel

——Insulation: Magnesium Oxide (MgO);

—— Sheath: 304L, 321, 316L, 347, 310, Inconel 600 or 825 alloy

-

Automobile sensor high temperature lead-out cable

Parameter name

Technical data

Conductor

Number of cores, cores

2

Diameter, mm

0.5

Insulation thickness, mm

0.3-1.0

Outer diameter of cable, mm

2.5-6.0

Sheath thickness, mm

0.3-0.6

Insulation resistance

Normal temperature

≥ 20 MΩ

300℃

≥ 5 MΩ

600℃

≥ 3 MΩ

900℃

≥ 40 kΩ

Operating temperature

Continuous operation, ℃

≤ 900

Short-time operation, ℃

950

Structural materials

(optional)

Conductor

Nichrome, Inconel 600, pure nickel, 310S, 310H Insulation

High purity MgO, Al2O3, SiO2 Sheath

304L, 321, 316L, 310S, 310H, Inconel 600, 825 alloy Mineral insulated cable for core instrument system

Nuclear mineral insulated control cable

Parameter name

Technical data

Conductor

Number of cores, cores

2-14

Diameter, mm

0.30-1.80

Insulation thickness, mm

0.58-0.75

Outer diameter of cable, mm

3.0-16.0

Sheath thickness, mm

0.25-1.60

Insulation resistance

Room temperature (25℃±5℃)

≥ 10000 MΩ

200℃

≥ 1000 MΩ

400℃

≥ 100 MΩ

Voltage test

Room temperature (25℃±5℃)

≥ 1000Vdc / 10s

200℃

≥ 1000Vdc / 10s

Insulation dielectric capacitance, pF/m

≤ 210

γ Radiation dose, Gy

≥ 2 × 106

Maximum temperature tolerance

≥ 900℃ / 2min

Structural materials

(optional)

Conductor

Copper, nickel-chromium alloy, pure nickel, K indexed thermocouple wire (nickel-chromium-nickel aluminum or nickel-chromium-nickel silicon) Insulation

High purity MgO, Al2O3, SiO2 Sheath

304L, 321, 316L, Inconel 600, 825 alloy Nuclear mineral insulated signal cable

Parameter name

Technical data

Coaxial cable

Double shielded cable

Triax cable

Conductor

Number of cores, cores

1

Diameter, mm

0.20-3.18

Insulation thickness

Internal insulation, mm

0.35-6.1

External insulation, mm

-

0.40-1.0

Outer diameter of cable, mm

4.0-19.1

3.0-19.1

Sheath thickness, mm

0.25-1.60

0.30-1.90

Characteristic impedance, Ω

50±5

Insulation resistance

Core wire-inner shield

≥ 10000 MΩ

Inner shield-outer shield

-

≥ 10000 MΩ

γ Radiation dose rate, Gy/h

≥ 2 × 106

Maximum temperature tolerance

≥ 900℃ / 2min

Structural materials

(optional)

Conductor

Copper, nickel-chromium alloy or pure nickel Internal insulation

High purity MgO, Al2O3, SiO2 Internal shielding

-

Copper, 304L, 321, 316L External insulation

-

High purity MgO, Al2O3, SiO2 External shielding

-

-

Copper

Sheath

304L, 321, 316L, Inconel 600, 825 alloy Nuclear hydrogen igniter

Parameter name

Technical data

Working voltage, Vdc

24

Rated power, W

145

Operating environment temperature, ℃

200

Direct heating element, mm

26

Length of heating element, mm

70

Rising rate

≥ 926.7℃ / 2min

Protection level

IP66

Neutron detector

Specific structural dimensions and performance parameters need to be customized or developed according to your needs.

Forced cooling type hollow conductor mineral insulated cable

Parameter name

Technical data

Nominal cross-section of conductor, mm2

150

185

240

300

400

500

600

740

800

Nominal outer diameter of conductor, mm

18.6

20.4

23.4

27

29

34.4

36.5

40

44

Nominal wall thickness of conductor, mm

3.0

3.3

3.9

4.3

5.3

5.6

6.2

6.9

7.3

Nominal thickness of insulation, mm

3.0

Outer diameter of metal sheath, mm

27

29

32

36

38

44

46

50

54

Nominal thickness of sheath, mm

1.2

1.3

1.3

1.5

1.5

1.8

1.8

2.0

2.0

Number of conductor cores

1 core

Insulation resistance, MΩ

≥ 1000 MΩ·km (when the cable length is less than 100m, ≥ 10000 MΩ)

Voltage

Experiment

Room temperature (25℃±5℃)

2500V/5min, no breakdown

200℃±10℃

1500V/5min, no breakdown

Rated voltage, Vac

750

Conductor material

Copper or chromium zirconium copper alloy

Insulation material

MgO

Sheath material

304L, 321, 316L, 316LN, Inconel 600 or 825 alloy

Note: Products other than the specifications in the above table can be customized according to your needs.

Mineral insulated cables for other high temperature, high pressure and strong corrosion occasions

Specific structural dimensions and performance parameters need to be customized or developed according to your needs.

-

Special-purpose mineral insulated cables are composed of conductive cores, tightly compacted mineral insulating powders and metal sheaths. They have excellent characteristics such as high temperature resistance, radiation resistance, corrosion resistance, and high mechanical strength. However, due to their mineral powder insulation layer There is an extremely fine air gap that cannot be eliminated, so it is easy to absorb moisture when exposed to the air and reduce its insulation resistance.

In order to ensure the insulation performance of the cable and avoid damage during use, the following items should be paid attention to when storing and using:

1. The cable should be stored in a dry, shaded room, and take measures to prevent rain, moisture, immersion, corrosion, and damage protection for the temporary termination of the cable.

2. When it is necessary to remove the temporary termination or cut the cable, such as making the termination, it should be implemented in an indoor environment with a humidity below 30%, and the termination should be completed within 20 minutes after the removal or cutting.

3. When making the cable end, the loose mineral insulating powder should be removed from the port, and the exposed conductor and the outer surface of the metal sheath at least 1cm long at the port should be cleaned with clean cotton yarn or fine sand.

4. After the temporary termination of the cable is removed or cut, if it cannot be terminated within 20 minutes, it should be placed in a dry oven or other similar environment with a temperature of not less than 150℃ for storage to prevent the cable from absorbing moisture .

5. After the cable is cut, if it is not used for a short period of time, it should be temporarily sealed with hot melt adhesive and heat shrinkable tubing, and stored as required.

6. If you find that the temporary end of the cable is damaged or the insulation is reduced, you can take one of the following two ways to deal with it:

——Remove the damaged temporary end of the cable, use a blowtorch to displace the damp end, until the specified insulation value is reached, immediately use hot melt glue and heat shrink tubing to temporarily seal the end;

——Remove the temporary end caps at both ends of the cable, and treat them in an oven or heat source at a temperature not less than 200℃, until the insulation reaches the specified insulation value, immediately use hot melt glue and heat shrink tubing Temporarily capped.

7. When welding the cable sheath, ensure that the metal sheath is electrically and reliably connected to the grounding wire of the welding machine.

8. When the cable is installed, except for the forced cooling type hollow mineral insulated cable, the bending radius of the cable should meet the following limits:

——Cables with an outer diameter of 5mm and below: The minimum bending radius is not less than 3 times the outer diameter of the cable;

——Outer diameter 5mm-10mm (including 10mm) cable: the minimum bending radius is not less than 4 times the cable outer diameter;

——Outer diameter 10mm-15mm (including 15mm) cable: the minimum bending radius is not less than 6 times the outer diameter of the cable;

——Cables with an outer diameter of 15mm and above: the minimum bending radius is not less than 10 times the outer diameter of the cable;

9. The minimum radius of cold bending of the forced cooling hollow mineral insulated cable should not be less than 50 times the outer diameter of the cable.

-

Automobile sensor high temperature lead cable

Mineral insulated cable for core instrument system

Nuclear mineral insulated control cable

Nuclear mineral insulated signal cable

Nuclear hydrogen igniter

Neutron detector

Forced cooling type hollow conductor mineral insulated cable

Mineral insulated cables for other high temperature, high pressure and strong corrosion occasions

Previous

Next

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!