Oil well heating system

Oil well electric heating system is a complete set of downhole electric heating technology and device specially developed by Jiusheng electric for the thermal recovery process of heavy oil, super heavy oil, high wax oil and gas and shale oil,

Classification:

Key words:

Oil well heating system

- Description

- Characteristic

- Parameter

- Laying and installation

- Application

-

- Commodity name: Oil well heating system

Oil well electric heating system is a complete set of downhole electric heating technology and device specially developed by Jiusheng electric for the thermal recovery process of heavy oil, super heavy oil, high wax oil and gas and shale oil,

The oil well electric heating system is a complete set of downhole electric heating technology and equipment developed by Jiusheng Electric for the thermal recovery process of heavy oil, super heavy oil, high wax oil and gas and shale oil.

It can be applied in both onshore and offshore oilfield exploitation, which can effectively enhance the oil recovery rate,

Ensure the stability of oil and gas production, increase oil and gas production capacity, and reduce the total cost of oil and gas extraction.

The system uses the principle of thermal effect of current to directly convert the electrical energy of the industrial frequency power supply into thermal energy.

Long-line heating, with good high temperature performance.

The heating length can reach more than 2000m, the highest voltage level is 4160Vac,

The maximum unit heating power can reach 5000W/m,

The highest temperature that can withstand is up to 1000°C.

The system can be widely used:

——Heavy oil heating and viscosity reduction process;

——Heavy oil thermal oil recovery process: fire flooding, steam flooding, steam huff and puff;

——Oil and gas well anti-coagulation wax removal;

——In-situ conversion process heating of shale oil.

In the field of heavy oil applications, compared with traditional chemical and physical viscosity reduction mining processes, the system uses clean electric energy, is environmentally friendly, easy to install and use, and has lower investment, operation and maintenance costs.

In addition, the system can reduce or even eliminate the use of thin oil or other chemical substances and water consumption, and the risk of affecting or damaging the environment is very low.

We can provide the following services according to your needs:

(1) Design and selection of oil well electric heating system;

(2) Facilities for the electric heating system of oil wells;

(3) Drilling operation of electric heating system of oil well;

(4) Operation and maintenance of oil well electric heating system.

-

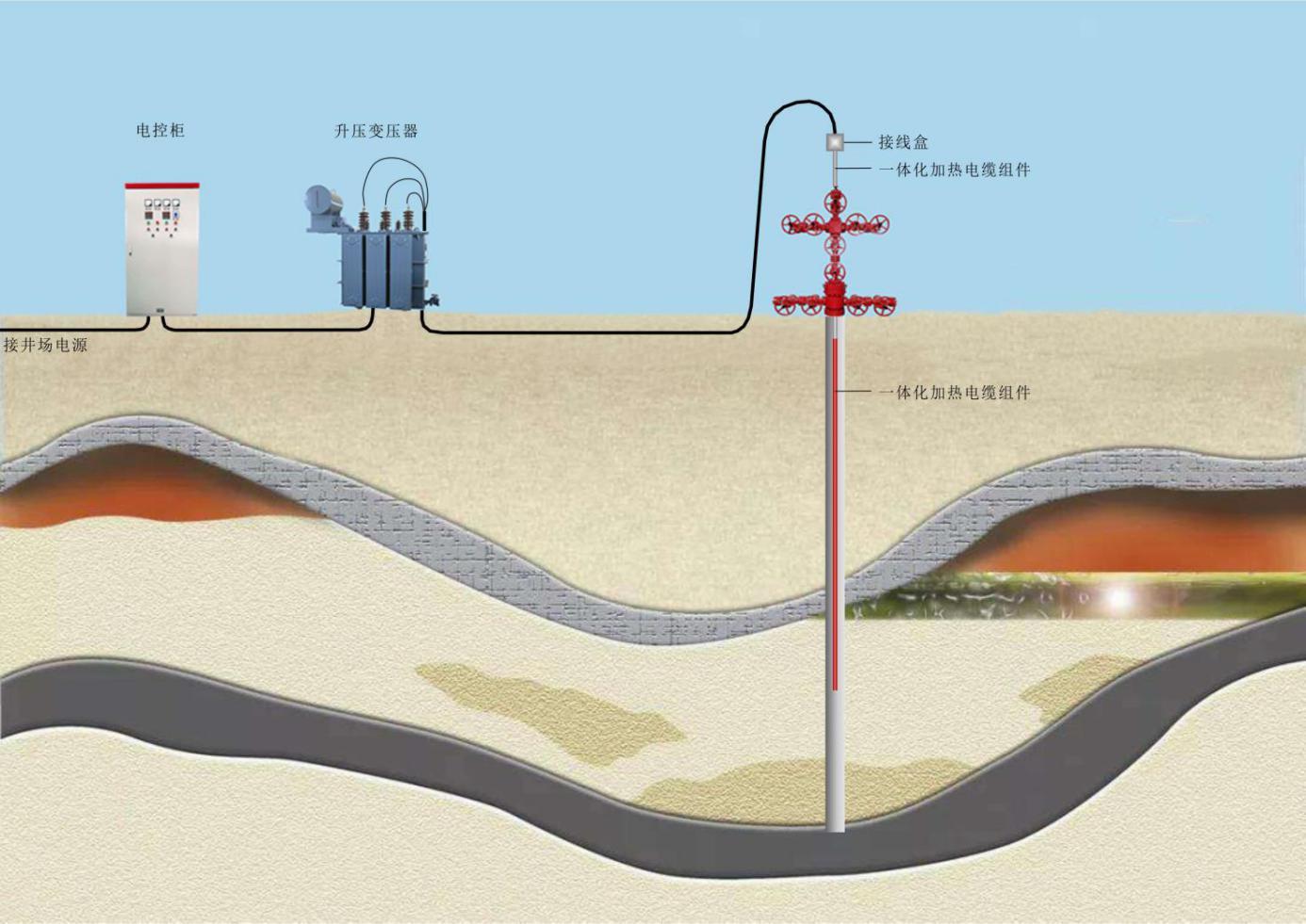

The oil well heating system takes the integrated mineral insulated heating cable (integrated cable for short) as the core component of the cold and hot section, and is equipped with electric control cabinets, step-up transformers and other electric control systems and installation accessories to form a complete electric heating system.

Integrated cable assembly

Structure

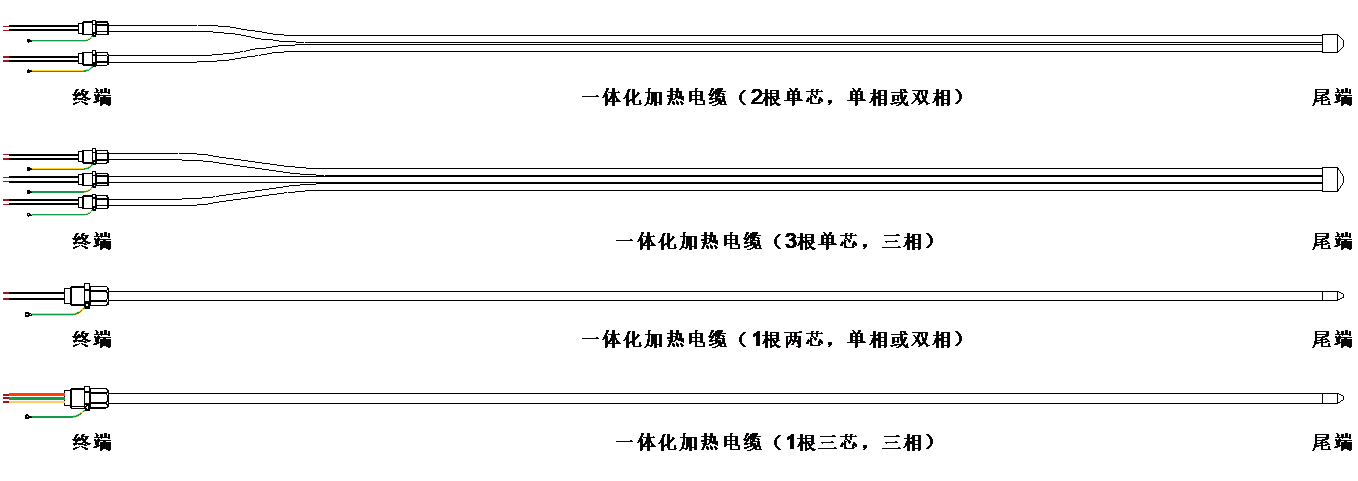

Composed of integrated cables, terminals and tail ends, usually prefabricated by the manufacturer's factory into heating devices that can be used directly in the well. For customers who have the corresponding design and processing capabilities, they can also make their own matching terminals and tail ends into heating devices.

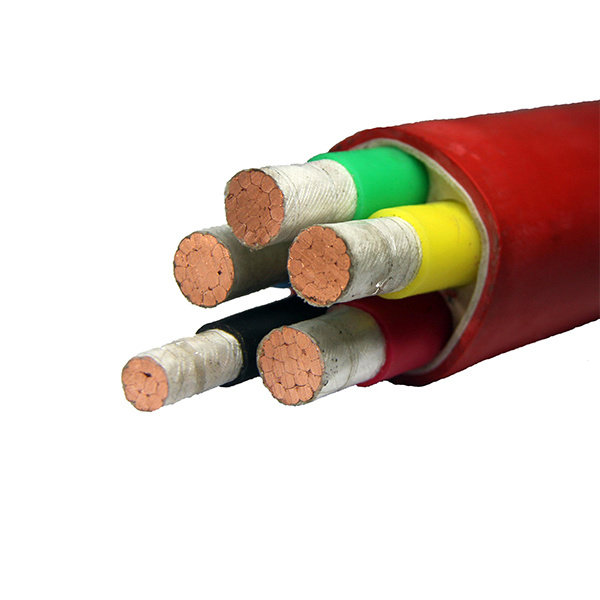

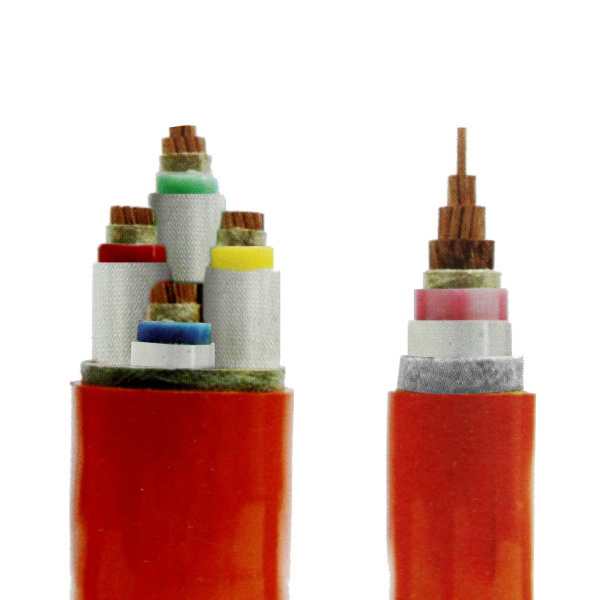

The integrated cable is composed of a cold end cable with the same outer diameter (commonly known as “cold section”) and a heating cable (commonly known as “hot section”), forming a consistent and continuous outer diameter during the manufacturing process One-piece metal sheathed mineral insulated cable. Where:

——Cold section: used for power transmission of heating cables, without obvious heating;

——Heat section: The heat effect of current is used to convert the introduced electric energy into heat energy, which generates obvious heat and has a higher temperature.

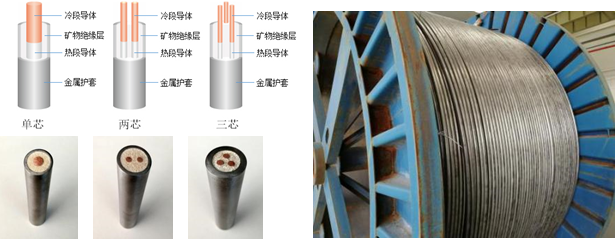

The structure is composed of cold and hot conductors, tightly compacted mineral insulating powder and metal sheath. According to the number of conductor cores, there are the following three structural forms:

(1) Single core, applied to:

——Three-phase electrical circuit (3 cables),

——Two-phase electrical circuit (2 cables),

——Single-phase electrical circuit (2 cables);

(2) Two cores, used in single-phase or two-phase electrical circuits;

(3) Three cores, used in three-phase circuits.

l

MaterialsThe structural materials of the integrated cable are shown in the following table, and the metal sheath material should be optimized according to the use temperature and the corrosiveness of the surrounding medium, so as to ensure the expected economic life.

Structure name

Material Material

Conductor

Cold section

Copper

Hot segment

Copper, copper-nickel alloy, nickel-chromium alloy

Mineral powder insulation layer

MgO powder

Metal sheath

300Series of austenitic stainless steel: 321, 316, 317, 347, 309, 310, etc.

Nickel-based alloy: Inconel 600, 825 corrosion resistant alloy

Electrical control system

The system consists of an electric heating control cabinet, a step-up transformer, a junction box and a well connecting cable, which is used for the operation control and monitoring of the oil well heating system to realize the economic operation of the system.

The electric control cabinet has the functions of leakage, short circuit, phase loss, over current, over voltage and over temperature protection, which provides a full range of protection for the safe operation of the electric control system. Equipped with a voltage regulator, used for system soft start and output power adjustment, which can avoid the impact on the power grid when the high-power oil well heating system starts.

The operation control method of the system adopts double closed-loop control. The inner loop is the power loop. The voltage regulator calculates the deviation between the actual output power value and the external given power value through the detected output voltage and current value. PID calculation automatically adjusts the output power; the outer loop is a temperature loop, which passes the temperature sensor inspection

The measured process temperature is fed back to the temperature controller or PLC temperature control module, and compared with the given process temperature. The PID calculation automatically adjusts and outputs the given signal of the voltage regulator to eliminate the heating environment. The influence of a variety of interference factors can realize the precise temperature control of the system.

The step-up transformer is used to step up the output voltage of the power regulator to meet the working voltage requirements of the integrated cable assembly with a voltage level of more than 1140V. The step-up transformer is an outdoor oil-immersed transformer, which requires less maintenance and strengthens its heat dissipation area, making it more reliable in operation.

In addition, the electronic control system can add a communication module according to your needs to transmit the system operation data information to the upper-level workstation in time, and accept the workstation's instructions to realize the remote monitoring and control of the system.

-

Heavy oil well bore electric heating system

Parameter name

Directly into the well

Nesting into the well

Tie into the well

Rated voltage, Va.c.

380/220, 660/380, 1140/660, 1500/860

1140/660, 1500/860, 1980/1140

Outer diameter of cable, mm

16-32

7.8-15.4

Heating length, m

≤ 2500

≤ 3000

≥ 2000

Cable core number

3-core

1 core (3 combinations)

Unit power1), W/m

80, 100, 125, 150, 200, 250

Outlet temperature2), ℃

65-98

Sheath material3)

321, 316, 317, 347, Inconel 600, 825 corrosion resistant alloy

Tensile strength, MPa

≥ 620 (normal temperature)

Note: 1) The unit heating power in the table is a common value, if it is not in the listed range, it can be designed separately according to your needs;

2) The outlet temperature can be heated to a higher temperature according to the needs of the viscosity reduction process;

3) The sheath material needs to be optimized according to the corrosiveness of the crude oil components to metal materials.

Thermal oil production electric heating system

Parameter name

Steam drive and steam stimulation and heat tracing

Fire drive heating

Oil layer heating

Rated voltage, Va.c.

660/380, 1140/660, 1500/860

660/380, 1140/660, 1500/860, 1980/1140, 2600/1500

Unit power1), W/m

150, 200, 250, 300

1500, 2000, 2500, 3000

900, 1200, 1500, 2000

Outer diameter of cable, mm

22.5, 25.4, 27, 30, 32

25.4, 27, 30, 32

16-32

Heating length, m

≤ 2500

≤ 300

≥ 400

Cable core number

3-core

2-core or 3-core

1 core (3 combinations) or 3 cores

Operating temperature, ℃

≤ 400

≤ 650

Sheath material2)

321, 316, 317, 310, 347, Inconel 600, 825 corrosion resistant alloy

Tensile strength, MPa

≥ 620 (normal temperature)

Note: 1) The unit heating power in the table is a common value, if it is not in the listed range, it can be designed separately according to your needs;

2) The sheath material needs to be optimized according to the corrosiveness of the crude oil components to metal materials.

Oil and gas well chemical wax anti-condensation electric heating system

Parameter name

Intermittent heating for wax removal and blockage removal

Continuous heat tracing for wax and condensation prevention

Design power1), kW

200-600

50-200

Rated voltage, Va.c.

660/380, 1140/660, 1500/860

380/220, 660/380, 1140/660

Outer diameter of cable, mm

21.4, 22.5, 25.4, 27, 30, 32

16, 19.2, 21.4, 22.5

Heating length, m

600-2000

Operating temperature, ℃

50-75

Sheath material2)

321, 316, 317, 347, Inconel 600, 825Corrosion resistant alloy

Tensile strength, MPa

≥ 620 (normal temperature)

Note: 1) The design power in the table is a commonly used range, if it is not in the listed range, it can be designed separately according to your needs;

2) The sheath material needs to be optimized according to the corrosiveness of the crude oil components to metal materials.

Downhole electric heating system for in-situ conversion of shale oil

Parameter name

1Core cable

3Core cable

2Root single phase (L-N)

2Root two-phase (L-L)

3Root three-phase

Three-phase

Voltage level, Va.c.

≤ 2400

≤ 4160

≤ 1500

Unit power, W/m

600-2300

600-3450

600-1200

Outer diameter of cable, mm

17.5-32

16-32

12.7-32

27, 30, 32

Heating length, m

400-2300

400-4000

400-6000

400-800

Maximum operating temperature, ℃

650 (continuous operation), 700℃ (intermittent operation)

Sheath material

321, 316, 317, 310, 347, Inconel 600, 825 corrosion resistant alloy

Tensile strength, MPa

≥ 620 (normal temperature)

Note: 1) The voltage level and unit power are not within the range listed in the table, and can be designed separately according to your needs;

2) The sheath material needs to be optimized according to the corrosiveness of the crude oil components to metal materials.

-

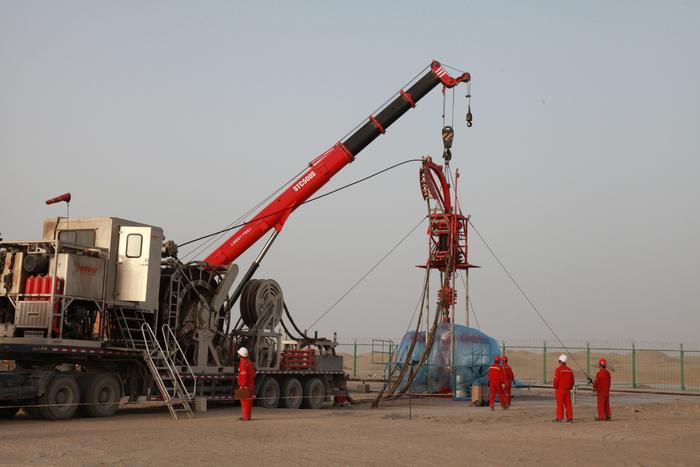

The entry operation of the integrated heating cable assembly can be selected according to its application method and site conditions:

(1) The coiled tubing injection head is used for direct entry into the well, which is suitable for direct entry and nested entry installation methods;

(2) Binding into the well with sucker rod, tubing or coiled tubing, suitable for lashing into the well installation method;

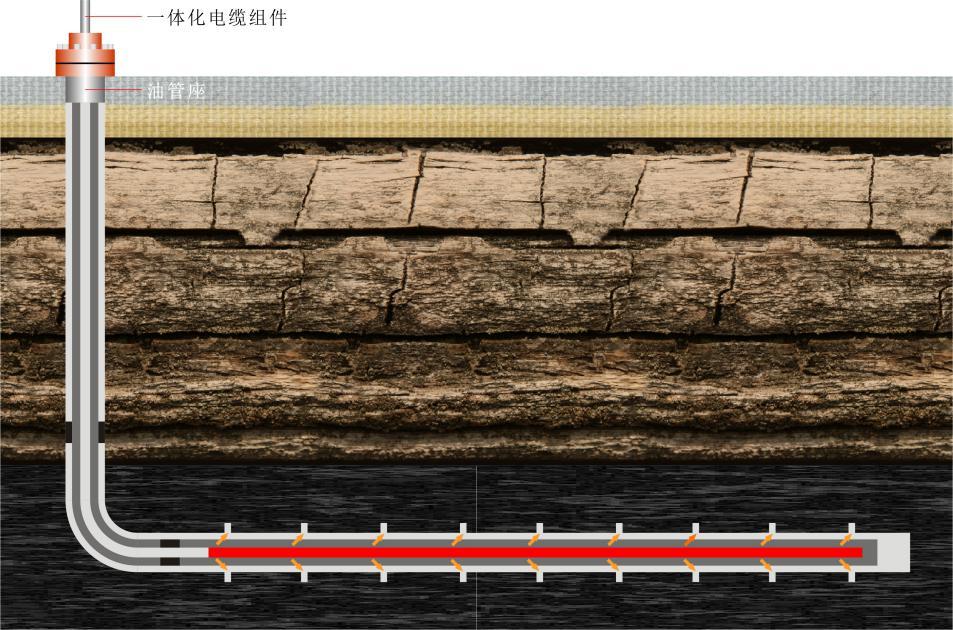

(3) After the integrated heating cable assembly is inserted into the coiled tubing, the coiled tubing operation vehicle is used to enter the well. The site needs to have the coiled tubing unfolded and tiled site conditions, which is suitable for direct oil layer heating and shale oil in-situ conversion heating applications Way;

(4) In the coiled tubing manufacturing process, the integrated heating cable assembly is wrapped in the coiled tubing. After the finished product, the coiled tubing operating vehicle is used to enter the well, which is suitable for direct oil layer heating and in-situ conversion heating of shale oil. .

-

Electric heating of heavy oil wells to reduce viscosity

Using the temperature-sensitive characteristics of the viscosity of heavy oil, the electric heating system of the oil well is used to heat the heavy oil in the wellbore and maintain it at a suitable temperature above the inflection point of the viscosity temperature, so that its viscosity is greatly reduced, thereby obtaining better flow. Sex, applied to:

(1) The wellbore of the mixed thinning and viscosity reduction process is heated and reduced to reduce the friction along the way of the heavy oil lifting process, thereby reducing or even eliminating the amount of thin oil blending, reducing the cost of blending, and increasing oil production;< /p>

(2) Increase the temperature before the pump and reduce the viscosity, reduce the resistance of heavy oil into the pump, make the heavy oil into the pump smoothly, and reduce the pumping depth and oil pump load, thereby reducing production and maintenance costs;

(3) Substitution of hot water injection and chemical viscosity reduction process to reduce operation, maintenance and post-processing costs.

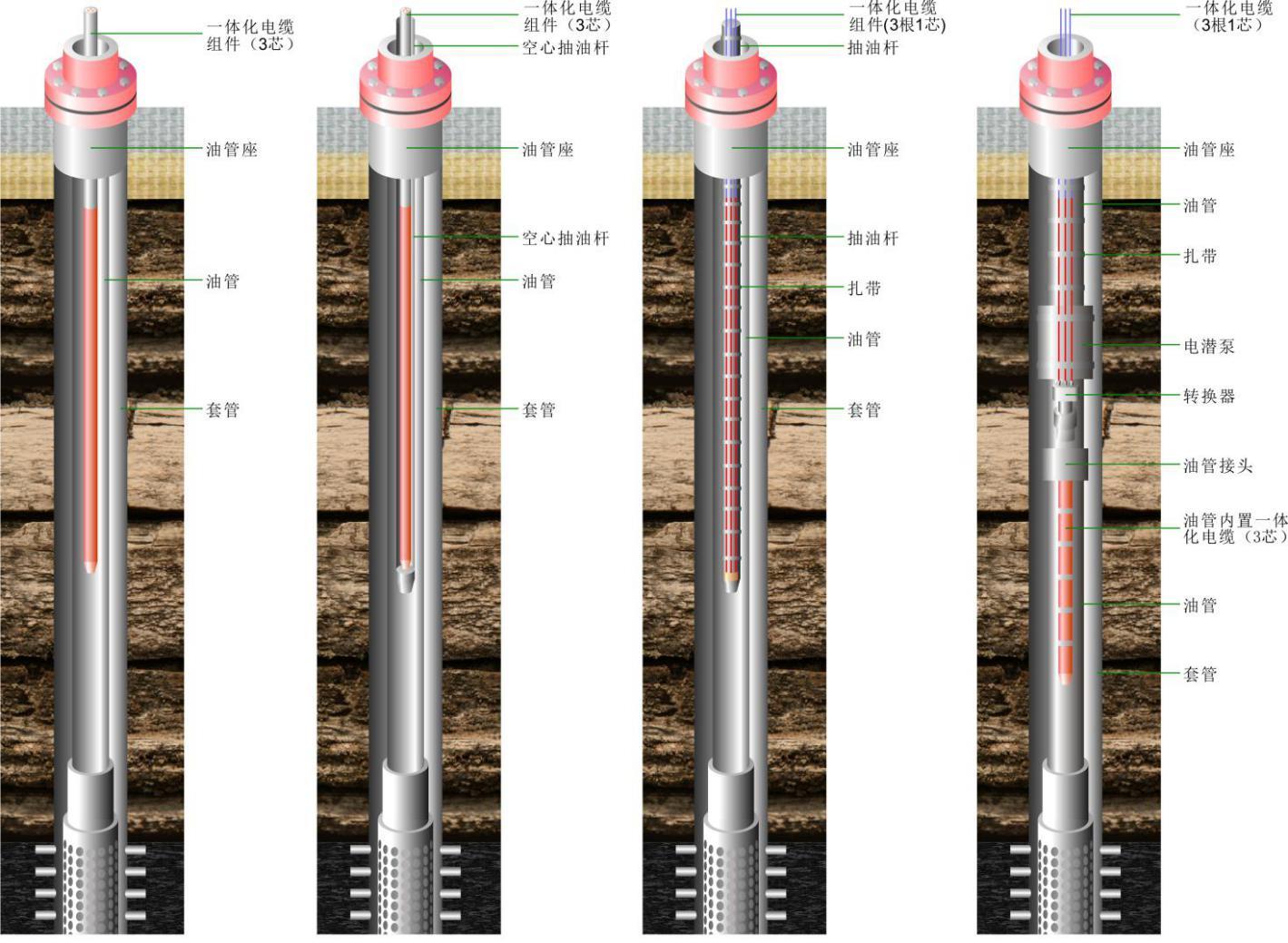

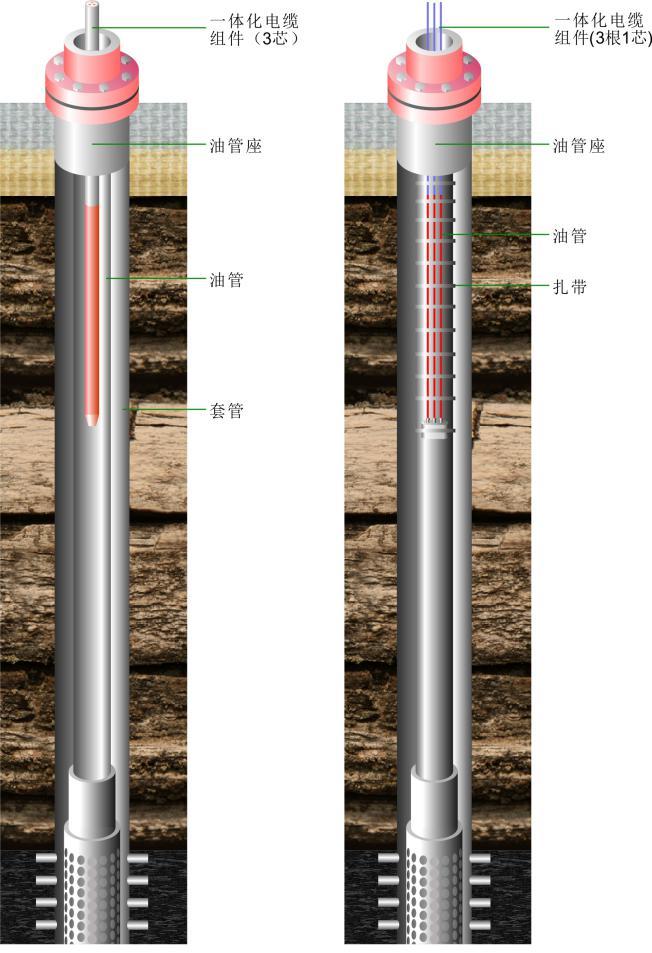

According to different applications, the integrated heating cable assembly can be installed in the well:

——Directly into the well: the three-core integrated cable assembly is directly lowered into the tubing from the center hole of the Christmas tree top valve, and suspended and fixed on the Christmas tree top valve flange of the self-spraying well or electric pump well. The heating depth can reach 2500m, which is suitable for self-blowing wells and electric pump wells;

—— Nesting into the well: Put the three-core integrated cable assembly into the hollow sucker rod or coiled tubing, and use the hollow sucker rod or coiled tubing to enter the well. The maximum heating depth can reach more than 3000m. Blowout wells, electric pump wells and rod pumping wells;

Direct into the well installation nested into the well installation lashing into the well installation add before the pump Heat tracing after heat pump

——Lashing into the well: tying three single-core integrated cables on the outer surface of the sucker rod or coiled tubing into the well, leading from the small four-way flanks of the Christmas tree for installation and external power connection, suitable for heating depths above 2000m Self-blowing wells and electric pump wells;

——The diameter of the three-core integrated cable assembly is built into the oil pipe in front of the pump, and the three-core integrated cable is converted into three single-core integrated cables through the converter, and the single-core cable is led out from the oil pipe. It is fixed on the outer surface of the oil pipe at the rear of the pump, and fixed and connected to the external power supply from the flanks of the big four-way of the Christmas tree, so as to realize the heating before the pump and the heating after the pump. If only the heating before the pump is considered, the flat cable of the well pump or three single-core mineral insulated cables can be used to introduce the working power supply for the cables after the pump and the pump.

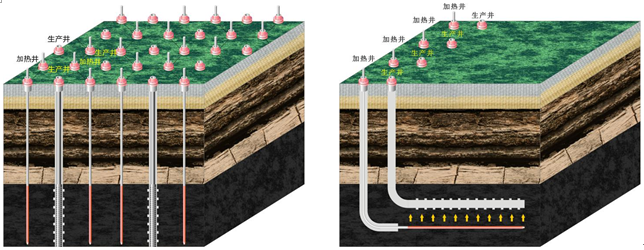

Thermal oil production process heating

Thermal oil production process heatingBased on the good high temperature performance of the integrated heating cable, it is:

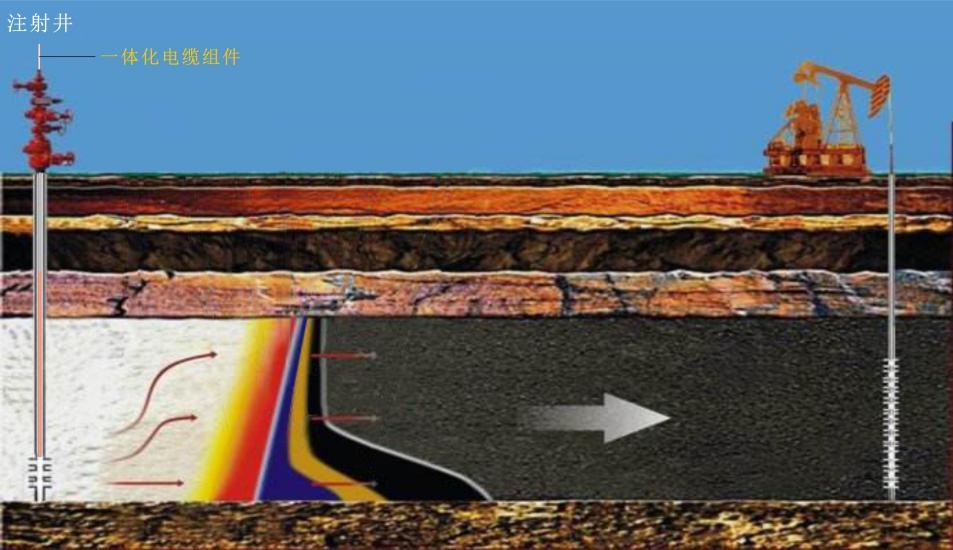

(1) Built in the compressed air delivery pipe of the fire flooding injection well, heating the compressed air along the way to make the temperature of the compressed air at the end reach the required process ignition temperature (above 400 ℃) to achieve oil layer ignition;

(2) The steam injection pipes of steam flooding and steam stimulation wells compensate for the heat loss in the steam transportation process, so that the end steam is maintained at the high temperature and high pressure when entering the well and injected into the oil layer, or normal temperature water is passed into the injection pipe to heat it High-temperature and high-pressure steam is injected into the oil layer to improve the recovery rate and recovery period;

(3) With the help of coiled tubing, it is placed in the oil layer and heated directly in the well, forming a high-temperature temperature field around it, so that the heavy oil is heated to a higher temperature and then collected by itself into the oil production well for exploitation.

High wax content well and gas well wax prevention and wax removal

High wax content well and gas well wax prevention and wax removalPlace the three-core integrated heating cable assembly directly into the wellbore of the high-wax well, use hollow sucker rods or coiled tubing to install it in the wellbore tubing of the high-wax well, or tie three single-core heating cables to the outside of the wellbore tubing. Installation, realization:

(1) Intermittent heating for wax removal and block removal

According to the cycle of waxing and clogging, intermittent power-on operation. When the oil (gas) output is at the lower limit, short-term power-on heating of the wellbore, melting the wax or gel condensed on the inner wall of the wellbore, and dredging the blocked pipe section , To realize the wax removal and plugging removal of oil/gas wells;

(2) Anti-wax and anti-condensation continuous heat tracing

Long-term energized operation keeps the oil/gas temperature in the wellbore always above the wax precipitation and gel temperature, prevents the condensation of wax or colloids on the inner wall of the wellbore, and ensures stable production of oil/gas wells.

In-situ conversion heating of shale oil

Set up heating wells at small intervals around or below the shale oil production well, and lower the integrated heating cable assembly into the heating well oil layer by means of coiled tubing, and heat the surrounding oil layers to about 320℃ after power-on Or higher conversion temperature, so that the heavy oil, bitumen and other organic substances in the shale oil layer can be converted into light oil and natural gas, which are then produced through production wells to realize the clean and efficient development and utilization of shale oil.

Previous

Next

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!