Heating Cable

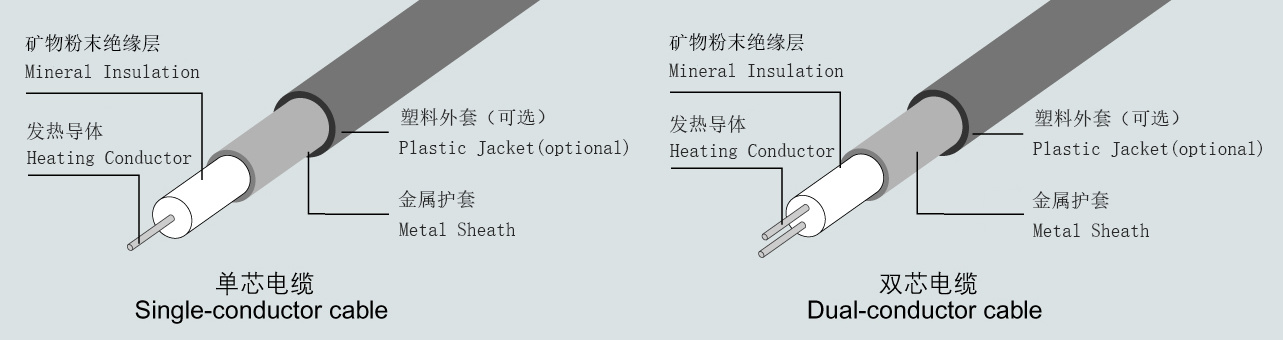

It is composed of a heating conductor, an insulating layer of tightly compacted mineral powder (usually magnesium oxide powder) and a metal sheath. For copper sheathed heating cables, a layer of high-density polyethylene (HDPE) or flame-retardant HDPE plastic jacket can be extruded on the outer circumference of the metal sheath according to the needs of anti-corrosion and anti-mechanical damage in the place of use. Commonly used structures are single-core and two-core, and can also be designed and provided with three-core and above mineral insulated heating cables according to your needs. The sheath materials include copper, cupronickel, austenitic stainless steel (304L, 321, 316L, 347, etc.), inconel and 825 high temperature corrosion resistant alloy, etc., which should be selected according to different operating temperatures and corrosive environments.

Classification:

Key words:

Heating Cable

- Description

- Product characteristics

- Product code

- Parameter

- Design and selection

- Laying and installation

- Application Area

-

- Commodity name: Heating Cable

It is composed of a heating conductor, an insulating layer of tightly compacted mineral powder (usually magnesium oxide powder) and a metal sheath. For copper sheathed heating cables, a layer of high-density polyethylene (HDPE) or flame-retardant HDPE plastic jacket can be extruded on the outer circumference of the metal sheath according to the needs of anti-corrosion and anti-mechanical damage in the place of use. Commonly used structures are single-core and two-core, and can also be designed and provided with three-core and above mineral insulated heating cables according to your needs. The sheath materials include copper, cupronickel, austenitic stainless steel (304L, 321, 316L, 347, etc.), inconel and 825 high temperature corrosion resistant alloy, etc., which should be selected according to different operating temperatures and corrosive environments.

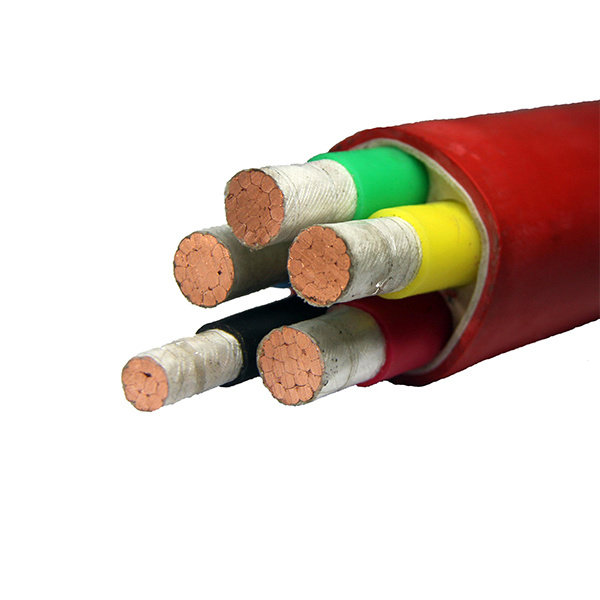

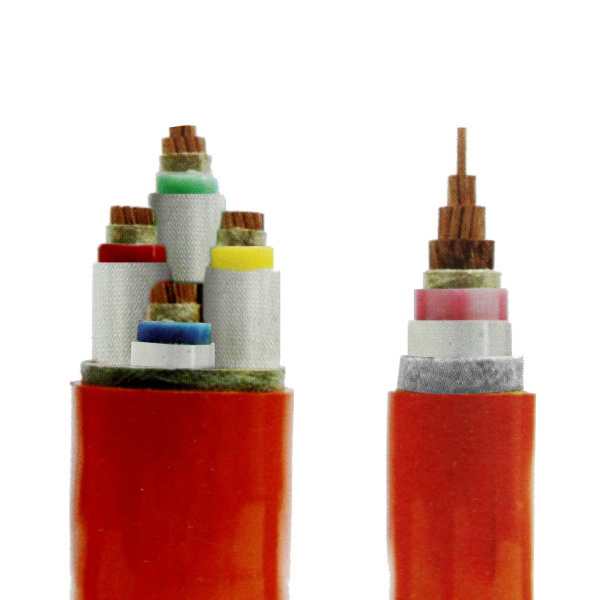

Product structure

Mineral Insulated Heating Cable

It is composed of a heating conductor, an insulating layer of tightly compacted mineral powder (usually magnesium oxide powder) and a metal sheath. For copper sheathed heating cables, a layer of high-density polyethylene (HDPE) or flame-retardant HDPE plastic jacket can be extruded on the outer circumference of the metal sheath according to the needs of anti-corrosion and anti-mechanical damage in the place of use.

The common structure is single-core and two-core, and three-core and above mineral insulated heating cables can also be designed and provided according to your needs.

Sheath materials include copper, cupronickel, austenitic stainless steel (304L, 321, 316L, 347, etc.), inconel and 825 high temperature corrosion resistant alloy, etc., which should be carried out according to different operating temperatures and corrosive environments Optional.

Mineral Insulated Heating Unit (Mineral Insulated Heating Unit)

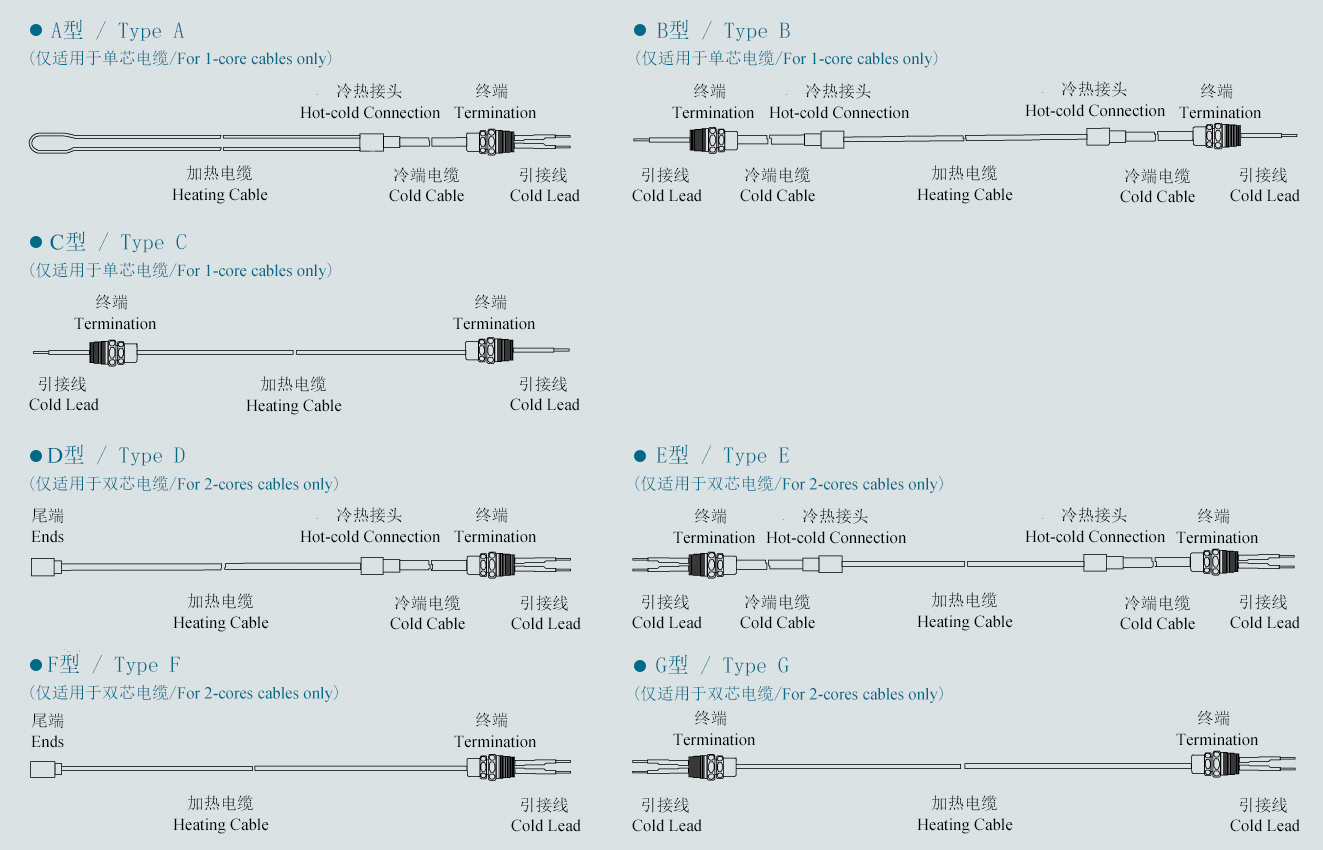

This product is based on the design and selection of mineral insulated heating cables, and is prefabricated in the manufacturer's factory for heating unit devices that can be directly connected to the power supply. It is usually composed of heating cables, hot and cold joints, cold end cables, terminals, tail ends, and lead wires. There are types A, B, C, D, E, F, and G. Types A, B, and C are only suitable for single-core heating cables, and types D, E, F, and G are only suitable for double-core heating cables.

-

High mechanical strength

The high-strength metal tube is used as the sheath, which forms a compact body with the conductor and mineral insulating powder during the processing. The structure is firm, the mechanical strength is high, and it is resistant to mechanical extrusion and bending.

Stable physical and chemical properties

The constituent materials are all inorganic materials with good thermal stability. When used under the rated temperature and set environment, the structure, electrical conductivity, dielectric strength, chemical composition and other mechanical, physical and chemical properties are quite stable.

Small temperature difference between inside and outside

The thermal resistance coefficient of magnesium oxide insulation is 3-5 times lower than that of most organic insulating materials. The small thermal resistance can make the heat transfer from the inner conductor to the metal sheath sharply, so the temperature difference between the conductor and the surface of the sheath is very small, which allows a larger current density.

High electric and heat conversion efficiency

Using the principle of the thermal effect of electric current (Joule-Lenz's law), pure resistance heats up, almost 100% of the electrical energy is converted into heat.

Electrical control is convenient

The working voltage is 50-60HZ power frequency, and the ON/OFF or PID temperature control is selected according to actual needs. The technology is mature, the operation is reliable, and the maintenance is small.

Corrosion resistance

According to the temperature of the environment and the corrosive medium, the appropriate metal sheath material can be selected to achieve the best corrosion resistance.

Radiation resistance

The inorganic materials used have good radiation resistance. The literature shows that when this type of cable runs at 200℃-700℃ and the neutron flux is 1021 neutrons/cm2, its technical performance actually does not occur. Changes can be applied to the core radiation area of nuclear power plants.

Explosion-proof certificate

The company's mineral insulated heating cable products have obtained the IEC Ex and ATEX explosion-proof certificates issued by the British CML.

Product name

IEC Ex certificate number

ATEX certificate number

Explosion-proof grade

Protection

Level

MICU & MIHC

Mineral insulated heating cable

IECEx CML 16.0075

CML 16ATEX3164

Ex e IIC T1 ~ T6 Gb

Ex tb IIIC T450℃~T85℃ Db

IP67

MICN

Mineral insulated heating cable

IECEx CML 16.0079

CML 16ATEX3169

Ex e IIC T1 ~ T6 Gb

Ex tb IIIC T450℃~T85℃ Db

IP67

MISS

Mineral insulated heating cable

IECEx CML 16.0080

CML 16ATEX3170

Ex e IIC T1 ~ T6 Gb

Ex tb IIIC T450℃~T85℃ Db

IP67

MIAL

Mineral insulated heating cable

IECEx CML 16.0081

CML 16ATEX3171

Ex e IIC T1 ~ T6 Gb

Ex tb IIIC T450℃~T85℃ Db

IP67

-

Mineral insulated heating cable

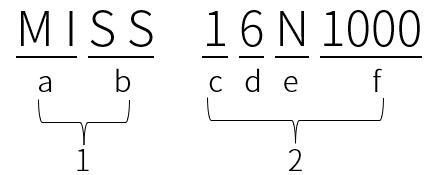

Code description:

Serial number

Name

Code

Code name

Interpretation meaning

1

Model

a

Product name

MI: Mineral insulated heating cable

b

Sheath material

CU: Copper sheath

HC: Copper sheath + HDPE jacket

HF: Copper sheath + flame-retardant HDPE jacket

SS: Stainless steel sheath

AL: 825 alloy sheath

2

Specifications

c

Number of conductor cores

1: Single core (1 core)

2: Double core (2 core)

d

Voltage rating

3: 300V

6: 600V

e

Heating conductor material

T: Copper

K: Copper-nickel alloy

N: nickel-chromium alloy

f

Unit conductor resistance

At 20℃, the nominal value of conductor resistance with a length of 1km (Ω/km)

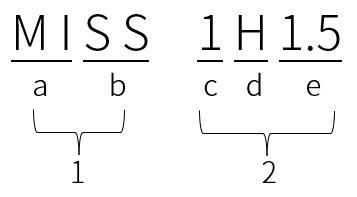

Mineral insulated cold end cable

Code description:

Serial number

Name

Code

Code name

Interpretation meaning

1

Model

a

Product name

MI: Mineral insulated cold end cable

b

Sheath material

HC: Copper sheath + HDPE jacket

HF: Copper sheath + flame-retardant HDPE jacket

SS: Stainless steel sheath

AL: 825 alloy sheath

2

Specifications

c

Number of conductor cores

1: Single core (1 core)

2: Double core (2 core)

d

Voltage rating

L: 500V

H: 750V

e

Conductor cross section

Nominal cross-sectional area of conductor (mm2)

Note: The model specifications of the bare copper sheathed mineral insulated cold-end cable can also be expressed in accordance with the method specified in GB/T 13033.1.

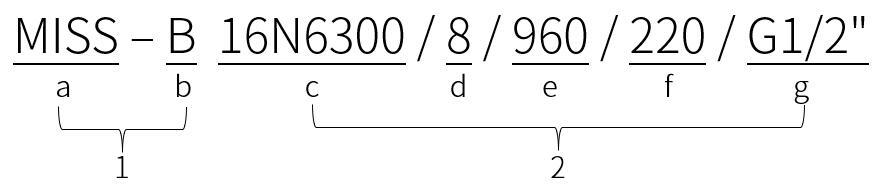

Mineral insulation heating element

Code description:

Serial number

Name

Code

Code name

Interpretation meaning

1

Model

a

Heating cable model

Design optional mineral insulated heating cable model

b

Component structure style

Designed component structure types: A, B, C, D, E, F, G type

2

Specifications

c

Heating cable specifications

Design and match mineral insulated heating cable specifications

d

Heating cable length

Design and matching mineral insulated heating cable length (m)

e

Design power

Component design power (W)

f

Rated voltage

Component rated working voltage (V)

g

Interface specifications

Installation thread specification of component terminal: M, G or NPT standard thread

-

300VCopper sheathed heating cable (model:MICU)

Specification code

Outer diameter

Nominal resistance of conductor at 20℃

Maximum manufacturing length

Unit weight

mm

Ω/km

m

Kg/km

23C3.4

12.4

3.4

200

698

23C4.4

11.3

4.4

220

571

23C5.8

10.4

5.8

240

476

23C8.6

9.0

8.6

260

351

23C11.4

8.4

11.4

280

299

23C13.8

8.0

13.8

300

268

23C17.2

7.6

17.2

320

239

23C23

7.1

23

340

205

23C34.4

6.6

34.4

360

174

23C49.2

6.2

49.2

380

151

23K160

10.4

160

220

477

23K240

9.0

240

240

351

23K320

8.4

320

265

299

23K384

8.0

384

280

268

23K480

7.7

480

300

244

23K640

7.1

640

320

205

23K960

6.5

960

350

169

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor.

300VWhite copper sheathed heating cable (model:MICN)

Specification code

Outer diameter

Nominal resistance of conductor at 20℃

Maximum manufacturing length

Unit weight

mm

Ω/km

m

Kg/km

23K160

10.4

160

202

477

23K240

9.0

240

267

351

23K300

8.4

300

292

302

23K380

8.0

380

320

269

23K480

7.7

480

352

244

23K620

7.1

620

433

206

23K960

6.5

960

458

169

23K1480

6.0

1480

390

141

23K1890

5.7

1890

433

126

23K2340

5.5

2340

471

117

23K3100

5.3

3100

500

107

23K4800

4.9

4800

547

92

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor.

300VStainless steel/825Alloy sheathed heating cable (model:MISS/MIAL)

Specification code

Outer diameter

Nominal resistance of conductor at 20℃

Maximum manufacturing length

Unit weight

mm

Ω/km

m

Kg/km

23C34

5.6

34

190

122

23K164

5.0

164

240

95

23K180

6.5

180

140

169

23K210

5.4

210

210

113

23K230

4.8

230

261

86

23K300

5.0

300

240

96

23K328

4.5

328

297

78

23K400

4.8

400

261

87

23K480

4.8

480

261

86

23K650

4.6

650

284

78

23K984

4.8

984

261

86

23K1000

4.1

1000

358

61

23K1300

3.8

1300

417

52

23K1600

4.3

1600

325

68

23K1968

4.8

1968

261

87

23K2000

5.0

2000

241

93

23K2297

4.5

2297

297

76

23K2400

4.8

2400

261

86

23K3000

4.6

3000

284

78

23K4593

4.0

4593

375

58

23N4600

4.8

4600

261

86

23N5577

4.0

5577

375

60

23N7500

4.6

7500

284

77

23N8200

4.0

8200

375

59

23N11200

4.4

11200

311

70

23N14000

4.2

14000

341

63

23N16400

3.5

16400

495

44

23N18000

3.8

18000

420

52

23N19685

3.5

19685

495

44

23N24600

3.0

24600

670

33

23N26000

3.6

26000

464

46

23N29500

3.0

29500

670

32

23N36000

3.4

36000

520

41

23N40000

3.4

40000

520

41

23N50000

3.6

50000

464

41

23N60000

3.6

60000

464

41

23N72000

3.4

72000

520

40

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor.

600VCopper sheathed heating cable (model:MICU)

Specification code

Outer diameter

Nominal resistance of conductor at 20℃

Maximum manufacturing length

Unit weight

mm

Ω/km

m

Kg/km

16C0.7

9.6

0.7

340

497

16C0.9

9.1

0.9

340

427

16C1.0

8.7

1.0

350

390

16C1.3

8.0

1.3

350

321

16C1.7

7.3

1.7

350

261

16C2.2

7.0

2.2

380

232

16C2.9

6.4

2.9

400

190

16C4

5.9

4

600

156

16C7

5.3

7

600

119

16C11

4.9

11

600

99

16C13

4.6

13

600

87

16C17

4.6

17

600

85

16C21

4.6

21

600

84

16C25

3.7

25

600

55

16C33

4.6

33

600

82

16C40

3.4

40

600

45

16C63

3.2

63

600

39

16K66

5.2

66

384

114

16K80

5.3

80

370

120

16K100

5.2

100

450

112

16K131

4.9

131

600

99

16K140

4.9

140

600

98

16K197

4.45

197

600

79

16K220

4.5

220

600

81

16K262

4.3

262

600

73

16K315

4.3

315

600

78

16K345

4.2

345

600

74

16K450

4.0

450

600

66

16K492

4.0

492

600

65

16K630

4.0

630

600

64

16K800

3.5

800

600

49

16K984

4.0

984

600

62

16K1280

3.7

1280

600

53

16K2000

3.6

2000

600

49

16K3000

3.6

3000

600

49

26C3.4

12.9

3.4

150

745

26C4.4

12.2

4.4

160

650

26C5.8

11.3

5.8

170

547

26C8.6

9.9

8.6

180

413

26C11.4

9.3

11.4

200

357

26C13.8

9.0

13.8

210

332

26C17.2

8.6

17.2

220

299

26C23

8.0

23

250

255

26C34.4

7.5

34.4

280

220

26C49.2

7.1

49.2

300

195

26K240

9.9

240

180

413

26K320

9.3

320

200

357

26K384

9.0

384

210

332

26K480

8.6

480

220

299

26K640

8.0

640

250

255

26K960

7.5

960

280

220

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor.

600VWhite copper sheathed heating cable (model:MICN)

Specification code

Outer diameter

Nominal resistance of conductor at 20℃

Maximum manufacturing length

Unit weight

mm

Ω/km

m

Kg/km

16C3

6.4

3

255

188

16C4

5.9

4

300

156

16C5

5.7

5

320

142

16C6

5.5

6

345

130

16C7

5.3

7

350

119

16C8

5.2

8

362

113

16C9

5.1

9

376

108

16C11

4.9

11

400

99

16C17

4.6

17

500

85

16C25

3.7

25

600

55

16C40

3.4

40

600

45

16C63

3.2

63

300

39

16K82

5.7

82

350

165

16C93

3.2

93

300

39

16K122

5.2

122

400

125

16K160

4.9

160

500

108

16K188

4.7

188

600

98

16K250

4.4

250

600

84

16K312

4.2

312

600

75

16K400

4.0

400

600

67

16K478

3.8

478

600

60

16K630

3.7

630

600

55

16K1000

3.4

1000

600

46

16K1600

3.2

1600

600

40

16K2210

3.2

2210

300

39

16K2400

3.1

2400

600

37

16K4150

3.0

4150

600

34

26K160

11.2

160

184

539

26K240

9.9

240

226

413

26K300

9.3

300

246

360

26K380

9.0

380

273

332

26K480

8.6

480

292

299

26K620

8.0

620

327

256

26K960

7.5

960

352

220

26K1480

7.1

1480

305

194

26K1600

6.0

1600

405

141

26K1890

6.8

1890

335

178

26K2340

6.4

2340

361

157

26K3100

6.2

3100

380

146

26K4800

5.8

4800

422

127

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor.

600Stainless steel/825Alloy copper sheathed heating cable (model:MISS/MIAL )

Specification code

Outer diameter

Nominal resistance of conductor at 20℃

Maximum manufacturing length

Unit weight

mm

Ω/km

m

Kg/km

16C2.1

6.8

2.1

130

214

16C2.8

6.0

2.8

165

165

16C3.4

5.9

3.4

170

153

16C3.6

6.1

3.6

160

160

16C5.3

5.3

5.3

210

118

16C8

4.7

8

150

91

16C8.5

4.7

8.5

150

90

16C13

4.3

13

190

73

16C21

4.0

21

220

61

16K40

5.8

40

180

149

16K50

5.4

50

210

127

16K60

5.2

60

220

115

16K80

4.8

80

200

96

16K100

4.7

100

160

90

16K120

4.5

120

170

81

16K131

4.0

131

215

63

16K153

4.2

153

195

70

16N160

6.5

160

150

188

16N200

5.9

200

180

154

16N250

5.3

250

220

124

16K328

4.0

328

215

60

16N400

4.7

400

280

93

16N500

4.5

500

300

84

16N630

4.3

630

200

75

16N900

3.9

900

230

60

16N1000

3.9

1000

230

59

16N1250

3.8

1250

210

55

16N1600

3.6

1600

270

49

16N2400

3.2

2400

350

38

16N2500

3.4

2500

300

43

16N2800

3.4

2800

300

42

16N3300

3.4

3300

300

42

16N4000

3.2

4000

350

37

16N5200

3.2

5200

350

37

16N6300

3.2

6300

350

36

16N10000

3.2

10000

350

36

16N20000

3.2

20000

350

36

26C8.4

9.8

8.4

60

386

26C13.4

8.7

13.4

80

296

26C21

7.9

21

95

238

26C34

7.3

34

110

198

26C54

6.3

54

150

146

26C85

5.6

85

190

114

26C130

5.3

130

215

101

26K180

7.9

180

95

245

26K260

7.4

260

110

210

26K360

6.8

360

130

175

26K500

6.4

500

147

153

26K650

5.9

650

173

129

26K1000

5.7

1000

185

118

26K1300

6.2

1300

156

143

26K2000

5.8

2000

179

123

26K3300

5.4

3300

206

105

26N4600

5.8

4600

179

123

26N8000

5.4

8000

206

105

26N13000

5.0

13000

241

89

26N27000

4.8

27000

261

81

26N40000

4.6

40000

284

74

26N60000

4.4

60000

311

68

26N72000

4.2

72000

341

62

Note: The nominal resistance of the double-core cable conductor is the resistance of the double-core loop per 1km, that is, twice the resistance of a single conductor.

Mineral insulated cold end cable specification table

Voltage level

Specifications

Number of conductor cores

Nominal cross section

(mm2)

Nominal outer diameter

(mm)

Conductor resistance at 20℃

Maximum (Ω/km)

Current carrying capacity

(A)

500V

2L1.5

2

1.5

5.7

12.1

20

750V

1H1.5

1

1.5

4.9

12.1

25

1H2.5

1

2.5

5.3

7.41

34

1H4

1

4

5.9

4.61

46

1H6

1

6

6.4

3.08

57

1H10

1

10

7.3

1.83

77

1H16

1

16

8.3

1.15

108

2H1.5

2

1.5

7.9

12.1

25

2H2.5

2

2.5

8.7

7.41

34

2H4

2

4

9.8

4.61

46

-

Applicable standards and norms

General

GB 50264 Code for Design of Industrial Equipment and Pipeline Thermal Insulation Engineering

GB/T 4272 General Rules for Equipment and Pipeline Insulation Technology

GB/T 8175 Design Guidelines for Equipment and Piping Insulation

JGJ 142 Ground Radiant Heating Technical Regulations

HG/T 20514 instrument and pipeline heat tracing and insulation design specification

SH/T 3126 Design Specification for Heat Tracing and Insulation of Petrochemical Instruments and Pipelines

Non-explosive environment

GB/T 32348.2 / IEC 62395-2 Industrial and Commercial Resistive Heating System Part 2: System Design, Installation and Maintenance Application Guide

IEEE Std 515 IEEE Standard for the Testing, Design, Installation, and Maintenance of Electrical Resistance Trace Heating for Industrial Applications

IEEE Std 515.1 IEEE Standard for the Testing, Design, Installation, and Maintenance of Electrical Resistance Trace Heating for Commercial Applications

Explosive environment

GB 3836.1 Explosive Atmosphere Part 1: Equipment General Requirements

GB/T 19518.2 Explosive Atmosphere Resistance Heat Tracing Part 2: Guidelines for Design, Installation and Maintenance

IEC 60079-0 Explosive atmospheres-Part 0: Equipment-General requirements

IEC 60079-30-2 Explosive atmospheres-Part 30-2: Electrical resistance trace heating-Application guide for design, installation and maintenance

Design requirements

1. Before the design of the heating system, adequate technical communication and exchange should be carried out to determine the project requirements, location and use environment. The information to be provided includes at least:

a) Project name, location, purpose and requirements of use;

b) Potential explosion hazard in the place of use (if it is an explosive environment, the explosion-proof grade and temperature group should be clarified);

c) A list of pipes, containers and accessories, including materials, specifications, dimensions, quantities and other information;

d) The composition, properties, quantity or flow rate of the medium in the pipeline or container;

e) Process pipeline diagram;

f) Corrosive media that may exist in the surrounding environment;

g) The highest temperature, lowest temperature and annual average wind speed of the place of use;

h) Insulation structure, material and thickness (if selected by the user), etc.

2. When designing and selecting the heating system, consider the most unfavorable conditions it may use and adapt to these unfavorable conditions. The worst cases include:

a) The maximum ambient temperature, usually 40℃, unless otherwise specified;

b) No wind (still air);

c) Use the minimum thermal conductivity of thermal insulation materials;

d) The design does not use temperature control or simulates temperature controller failure;

e) The heat tracing device operates under the rated voltage plus 10% of the voltage;

f) The conductor resistance value of the heater is the lower limit of the manufacturing tolerance.

3. If it is used under special conditions or the site conditions may be particularly harsh, these conditions should be stated in the engineering technical conditions.

4. Before calculating the electric heating power, first confirm the following purposes of electric heating:

a) Heat tracing: compensate the heat loss under the lowest ambient temperature condition to maintain the specified temperature of the workpiece;

b) Heating: Raise the temperature of the workpiece and its internal substances to the specified value within the specified time;

c) Heating and tracing.

5. The appropriate safety factor should be considered when calculating the electric heating power. The safety factor should be based on past experience, and its range is generally 1.1~1.25, usually 1.2. The following factors should be considered when selecting the safety factor:

a) Deterioration of thermal insulation performance;

b) Changes in power supply voltage;

c) The voltage drop of the power line;

d) Increased radiation and convection heat dissipation in high temperature applications;

e) Installation quality of insulation engineering.

6. When heating and tracing are required, the electric heating power shall be the larger value of the heating power and the heating power calculation result.

7. The heat loss of flanges, valves, brackets, pumps and other pipeline accessories can be converted into equivalent pipeline length for calculation. The converted length of heat loss of typical pipe accessories is as follows:

Nominal diameter

Valve type

Thread

Flange

Orifice plate

Flange

Pipeline

Support

Check valve

Pump

inch

mm

Spinning or welding

Flange connection

Butterfly valve

½

15

0.15

0.31

0

0.15

0.45

0.50

0.10

0.60

¾

20

0.23

0.46

0

0.15

0.45

0.50

0.18

0.90

1

25

0.31

0.61

0.31

0.15

0.45

0.50

0.26

1.20

1¼

32

0.46

0.61

0.31

0.18

0.50

0.50

0.31

1.20

1½

40

0.46

0.72

0.46

0.18

0.50

0.50

0.41

1.20

2

50

0.61

0.76

0.61

0.18

0.50

0.40

0.56

1.50

2½

65

0.69

0.91

0.69

0.18

0.50

0.40

0.64

1.80

3

80

0.76

1.07

0.76

0.18

0.50

0.40

0.71

2.00

4

100

1.22

1.52

0.91

0.25

0.65

0.40

1.02

3.00

5

125

1.52

1.83

0.91

0.25

0.65

0.40

1.32

4.00

6

150

2.13

2.44

1.07

0.25

0.65

0.30

1.93

4.50

8

200

2.90

3.35

1.22

0.28

0.68

0.30

2.70

6.50

10

250

3.81

4.27

1.22

0.28

0.68

0.20

3.51

8.50

12

300

4.57

5.03

1.52

0.41

0.81

0.20

4.02

10.00

14

350

5.49

5.94

1.68

0.43

0.98

0.15

4.94

11.50

16

400

6.55

7.01

1.83

0.55

1.10

0.10

5.05

14.00

18

450

7.77

8.23

1.98

0.55

1.10

-

6.27

16.50

20

500

8.69

9.14

2.13

0.68

1.33

-

7.19

18.50

24

600

10.36

10.87

2.44

0.81

1.51

-

8.76

22.00

30

750

12.19

12.80

3.05

0.98

1.68

-

10.89

25.50

36

900

14.02

14.63

3.66

1.36

1.96

-

12.52

30.00

Note: 1. The converted length of the pipe accessories in the table is the length of the pipe of the corresponding specification when calculating the heat loss.

2. The nominal pressure of the valves listed in the table is 2.0MPa and below.

8. When used in an explosive environment, even if the most unfavourable conditions are considered, the final installation power and the use, installation and operation of electric heating should not cause the explosion of the explosive mixture.

9. Each electric heating circuit should be equipped with over-voltage, overload, short-circuit, leakage and over-temperature protection, and the leakage current is usually set to 30mA.

Selection requirements

1. The following factors should be considered when selecting mineral insulated heating cables and components, and the installation and operation requirements under these factors should be met:

a) The tracing/heating temperature of the workpiece to be heated, the highest temperature the workpiece can withstand and the highest possible temperature;

b) The lowest ambient temperature of the place of use;

c) The corrosive substances and their concentrations that may exist in the place of use;

d) Pipeline heating/heating length or workpiece area, electric heating design calculation power;

e) Mechanical damage that may exist during installation and operation;

f) The installation space around the heated workpiece is limited;

g) The hazard of the place of use, the required explosion-proof grade and temperature group.

2. The sheath material should be selected according to the heat tracing/heating temperature of the workpiece, the highest possible temperature of the workpiece, and the corrosive medium that may exist in the place of use. The maximum sheath temperature allowed for various sheath materials is as follows:

Sheath material

Maximum sheath temperature allowed to be used, ℃

Bare copper

250

Copper+HPDE

90

White copper

400

300 series austenitic stainless steel

600

825 alloy

800

3. The heating element installation method can be parallel laying, spiral winding laying, or meandering (or W-shaped) laying. Parallel installation is preferred.

4. The specification of the heating cable should be based on the theoretical calculation result of the cold resistance of the heating conductor, and the closest specification whose nominal resistance is not greater than the calculation result should be selected from the heating cable specification table of the corresponding sheath material for preliminary selection. After the initial selection, the heating cable should be checked for operating parameters. If it does not meet the requirements, the heating cable specifications should be reselected and checked until the requirements are met. The verification content of the operating parameters of the heating cable includes:

a) The surface load or maximum sheath temperature of the heating cable;

b) Check the current density of the heating conductor.

5. The maximum heating temperature allowed by the heating element is as follows:

Power density

W/cm2

Maximum heat tracing temperature allowed for workpiece, ℃

HDPE outer sheath

Copper sheath

White copper sheath

Stainless steel sheath

825 alloy sheath

0.05

63

205

345

530

715

0.10

34

190

330

520

705

0.20

-

160

312

510

695

0.30

-

132

297

500

685

0.40

-

103

275

492

676

0.50

-

75

257

485

670

0.60

-

45

235

480

665

0.70

-

-

220

475

660

0.80

-

-

203

470

650

1.00

-

-

167

460

640

1.20

-

-

125

450

630

Note: 1. The data in this table is only applicable to the design and calculation of surface heat tracing of metal workpieces, and intermediate interpolation is allowed in the calculation.

2. The data in this table does not apply to surface electric heating in explosive environments. When used in explosive environments, please contact the manufacturer.

6. The selection power of the heating cable/component should not be less than the design power. When the heating/heating power exceeds 3kW, a three-phase power supply should be considered.

7. The length of the heating cable should be selected with an installation margin of 1%~1.5%.

8. The preferred sequence of heating element structure is as follows:

Number of conductor cores of heating cable

Working temperature

First series

Second series

The third series

Fourth series

Single core

≤150℃

Type C

Type B

Type A

-

>150℃

Type B

Type C

Type A

-

Two cores

≤150℃

F type

G type

Type D

Type E

>150℃

Type D

Type E

F type

G type

9. Option of cold end cable:

a) For the sheath material of the cold end cable, except for the cupronickel sheath heating cable, which can be copper or stainless steel, the other materials should be the same as the heating cable sheath;

b) The number of conductor cores of the cold end cable is selected according to the number of heating conductor cores of the heating cable and the structure of the heating element;

c) The nominal cross-section of the cold end cable and lead wire should be selected according to the maximum operating current of the heating element in accordance with the current carrying capacity specified in GB/T 16895.15 / IEC 60364-5-523;

d) The nominal cross-section of the protective grounding wire of the metal sheath should be selected according to the following table:

The conductor cross-section of the lead wire S, mm2

Minimum cross-section of grounding wire, mm2

S≤16

S

16

16

35≤S

S/2

-

Applicable standards and norms

GB/T 32348.2 / IEC 62395-2 Industrial and Commercial Resistive Heating System Part 2: System Design, Installation and Maintenance Application Guide

GB/T 19518.2 Explosive Atmosphere Resistance Heat Tracing Part 2: Guidelines for Design, Installation and Maintenance

03D705-1 Standard Atlas "Electric Heating and Heating Equipment Installation"

16S401 Standard Atlas "Pipe and equipment insulation, anti-condensation and electric heating"

IEEE Std 515 IEEE Standard for the Testing, Design, Installation, and Maintenance of Electrical Resistance Trace Heating for Industrial Applications

IEEE Std 515.1 IEEE Standard for the Testing, Design, Installation, and Maintenance of Electrical Resistance Trace Heating for Commercial Applications

IEC 60079-0 Explosive atmospheres-Part 0: Equipment-General requirements

IEC 60079-30-2 Explosive atmospheres-Part 30-2: Electrical resistance trace heating-Application guide for design, installation and maintenance

Storage and handling

1. The product should be stored in a dry room, centralized and classified, and measures should be taken to prevent the product from mechanical damage.

2. During the storage period, check once every three months, the appearance packaging should be complete, the signs should be complete, the end sealing should be tight, and the metal sheath should be free of rust.

3. The ambient temperature for product storage should not be lower than -15℃, and the relative humidity should not be higher than 85%.

4. Necessary measures to prevent rain, moisture, falling and other mechanical damage should be taken during the transportation process to prevent damage to the product and packaging.

Basic requirements

1. The installation of the heating system should be implemented in accordance with IEC 60079-30-2, IEEE 515 and any other applicable national and local electrical regulations.

2. The installation and commissioning personnel of the heating system shall have the qualifications of ordinary electricians, and shall receive professional technical training as required. The installation should be carried out under the supervision of a licensed electrician. When installing in a hazardous location, the electrician responsible for supervision should also undergo supplementary training on electric heating systems for explosive gas environments. Only professionally trained personnel can perform particularly critical tasks, such as the installation of connectors and terminals.

3. The heating system installation project should be constructed according to the approved design drawings, and any major construction modification should be approved in writing by the design representative.

4. The installation of the heating system should be carried out after the pressure test of all pipelines and piping accessories has been completed. Insulation materials can only be constructed after the electric heating has been installed and tested.

5. All coatings or finishes on the heated surface should be compatible with the operating conditions of the heating system.

6. The installation of the heating system should be coordinated with the installation of pipelines, insulation materials and instruments to ensure that the tasks are completed as planned.

7. The insulation resistance and the DC resistance of the conductor should be tested before and after the installation of the heating element, before and after the construction of the insulation material, and before the system is energized and debugged. When inspecting the insulation resistance, the 300V heating element is tested with a DC 500V insulation meter, and the 600V heating element is tested with a DC 1000V insulation meter. The measured insulation resistance value should not be less than 20MΩ.

8. The grounding wire of the heating element must be connected to the grounding terminal of the device and grounded reliably.

9. The minimum installation and operating temperature of the heating element is -15℃.

10. The minimum bend of the copper or cupronickel sheathed heating cable is as follows:

Outer diameter of heating cable D, mm

D<7

7≤D<12

12≤D<15

D≥15

Minimum bending radius Rmin, mm

2D

3D

4D

6D

11. The minimum bends of heating cables with stainless steel, Inconel or 825 alloy sheath are as follows:

Outer diameter of heating cable D, mm

D<5

5≤D<10

10≤D<15

D≥15

Minimum bending radius Rmin, mm

3D

4D

6D

10D

Pre-installation preparation

1. When the heating element to be installed is received, the routine inspection should be carried out first, including the confirmation of the product model, technical documents and quantity of materials. All heating cables and components should be checked to verify the product model, product and packaging markings, rated power, rated voltage, quantity and characteristics. Verification shall also be carried out when the installation instructions, certificates of conformity or the declaration of conformity of professional institutions are required to be provided.

2. Any sharp protrusions on the surface of the pipe and its accessories, such as welding slag, splash, etc., and cement, should be removed before the installation of electric heating.

3. Confirm whether the heat-traced workpiece conforms to the design drawings, such as the outer diameter of the pipeline, the length of the pipeline, and the number of pipeline accessories such as containers, valves, and flanges. When any part of the heated workpiece is changed, the heating cable may need to be adjusted, and the list of heating materials should be reviewed again.

4. The following tests should be carried out and recorded before installation:

a) Visually inspect whether the heating element is damaged, and finally check the continuity and insulation;

b) A single controller should be tested to ensure correct calibration, including but not limited to the set value, temperature operating range and temperature difference;

c) Check whether the control cabinet certificate and factory test records are complete, and check whether the control cabinet is damaged.

Installation requirements

1. The on-site release of the heating element should adopt a vertical or horizontal pay-off rack. When placing the heating element on a flat ground, care should be taken not to fold it hard and drag it for long distances on the ground.

2. Unless there are special regulations in the design, generally, the heating and cooling joints of the heating cable should be installed on the heated object first, and use this as the starting point, and then the heating cable is laid on the heated object. The hot and cold joints and subsequent heating cables should be kept straight and the necessary spacing.

3. The heating element should be fixed on the workpiece with appropriate fixings and fixed spacing to make the heating cable fully contact the workpiece. The fixing parts should be reasonably selected according to the shape of the workpiece to be heated, the heating temperature, and the material of the heating cable sheath. The recommended fixed spacing is as follows:

a) For the heating elements with parallel and straight coating, the fixed spacing is 200-300mm;

b) For winding heating elements, the fixed spacing should not exceed 2000mm;

c) Fixing parts should be appropriately added to elbows, flanges and other pipeline accessories.

4. The heating cable fixing parts can be wire ties, cable ties or hose clamps. The selection should match the working temperature of the heating cable, the sheath material and the shape of the workpiece, and the mutual electrochemical corrosion should be considered. The following fixtures are recommended:

a) Copper sheathed heating cable: bare copper wire, heat-resistant glass fiber rope or glass fiber tape can be selected;

b) HDPE outer sheath heating cable: cable ties, heat-resistant glass fiber rope or glass fiber tape with plastic protective layer can be selected;

c) Cupronickel or stainless steel sheathed heating cable: soft tie wire, cable tie, hose clamp or heat-resistant glass fiber rope or glass fiber tape of stainless steel can be selected;

d) For the heat tracing of large diameter round walls (such as tanks, kettles, tanks), planes and other workpieces, the fixing parts can be pre-punched fixing strips or metal clamps, or metal grids can be used with wire or The cable tie is bound and secured.

5. Both ends of the hot and cold joints of the heating element must be fixed on the workpiece to be heated, and it is strictly forbidden to bend within 5cm at both ends of the joint, otherwise the welding seal of the joint may be damaged.

6. The heating cable is required to be laid close to the surface to be heated, in order to achieve the best heat conduction effect. In places that are difficult to contact closely, such as valves, flanges, etc., suitable thermal conductive materials can be used to assist heat dissipation, such as thermal conductive mud, metal foil, and metal grid.

7. During the installation process, it is found that the heating cable has a suspended section. You can use a wood or rubber hammer to rectify it, or you can add a fixing piece to fix it.

8. The heating cable should be prevented from being wrapped in insulation material, otherwise it may cause the heating cable to overheat and shorten its service life.

9. Laying of heating cables is strictly forbidden to overlap or overlap. If there is a small amount of redundant heating cables at the end, it is necessary to carefully increase the parallel arrangement and never overlap the winding.

10. The cold end cable in the heating element does not generate significant heat. It is usually used to drill the insulation layer. When the insulation layer is drilled, a waterproof bend should be made locally to prevent rainwater from entering the insulation material downstream.

11. Once the MI heating cables or components are laid on the workpiece to be heated, the system is strictly forbidden to weld again. If the owner does need partial disassembly, replacement and re-welding, he should truthfully report the owner’s hazards. Before moving welding, all the heating elements on the system should be dismantled to free up enough construction space, and a special person should be assigned to monitor the whole process until the process construction is qualified, and the heating element installation should be resumed, and the abnormal process should be recorded in detail.

12. The outer insulation material of the workpiece to be heated should be weather-resistant, waterproof, and anti-seepage measures to protect the heating element from external erosion and damage.

-

Chemical industry

The heating or tracing of process pipelines and accessories, pumps;

The heating or tracing of reactors, cracking furnaces, vaporizers, flash evaporators, storage tanks, storage tanks and other devices and containers.

Petroleum field

Heating or tracing of Christmas trees, crude oil technology pipelines, valves, oil pumps, storage tanks and related processing devices;

Heavy oil wellbore heats up to reduce viscosity;

Oil and gas well wax prevention and deblocking.

Metallurgical industry

Heating or tracing of chemical pipelines, storage tanks, etc.;

The coal-fired dust collecting ash hopper is heated.

Power Station

Oil-fired power station: oil pipeline, container oil supply heating and heat tracing;

Hydropower station: pipeline antifreeze heating and heat tracing;

Nuclear power plants: heating or tracing of pipelines, valves, pumps, storage tanks, etc. of various systems, and preheating of the reactor sodium loop;

CSP stations: heating and tracing of lava pipelines and accessories, lava pumps, collectors, storage tanks, etc.

Natural gas

Gas station vaporization heat compensation;

Air tank water sealing heating;

Catalytic reaction heating;

The heating or tracing of natural gas product pipelines and related accessories and devices.

Architecture field

Quick drying of cement, pre-drying and heating of refractory bricks;

Floor heating for residential and industrial buildings;

Roof melting ice and snow drop load;

Gutter and downpipe anti-icing and heating.

Ship field

Deck and cabin anti-condensation heating;

Water and steam pipelines and related devices are heated or traced.

Horticulture field

Winter heating of greenhouse crops;

Prevent ice and snow in the greenhouse;

Promote seed growth and heating;

Lawn maintenance and heat preservation.

Roads, traffic fields

Roads, ramps, sidewalks, steps, bridges and tunnels are heated by melting ice and snow;

Snow and ice melting in sports fields, airport runways, and helipads;

Anti-freezing of railway turnouts, melting of icicles on the dome of tunnels, and melting of snow and ice on open-air platforms.

Previous

Next

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!