Class B1 flame-retardant and fire-resistant cable

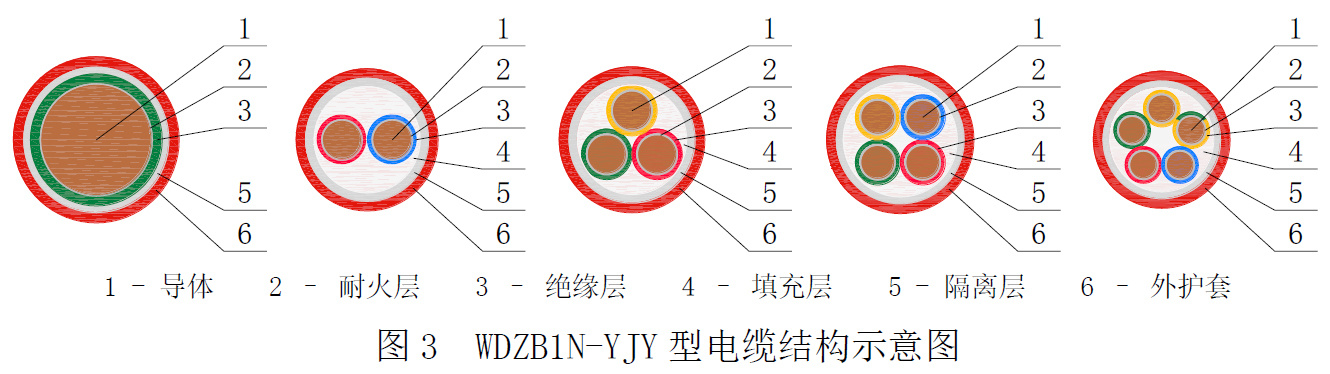

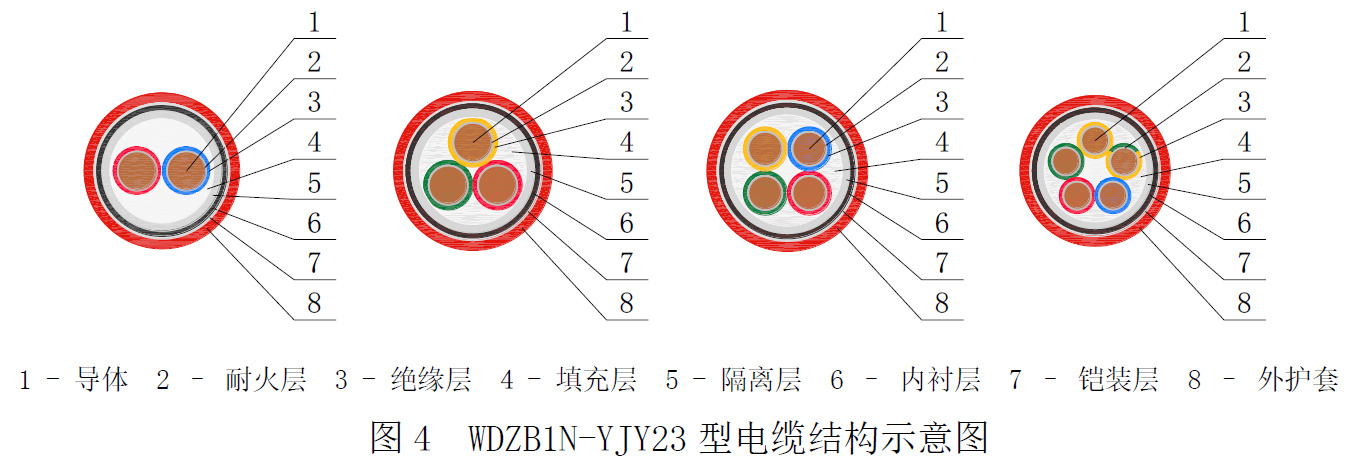

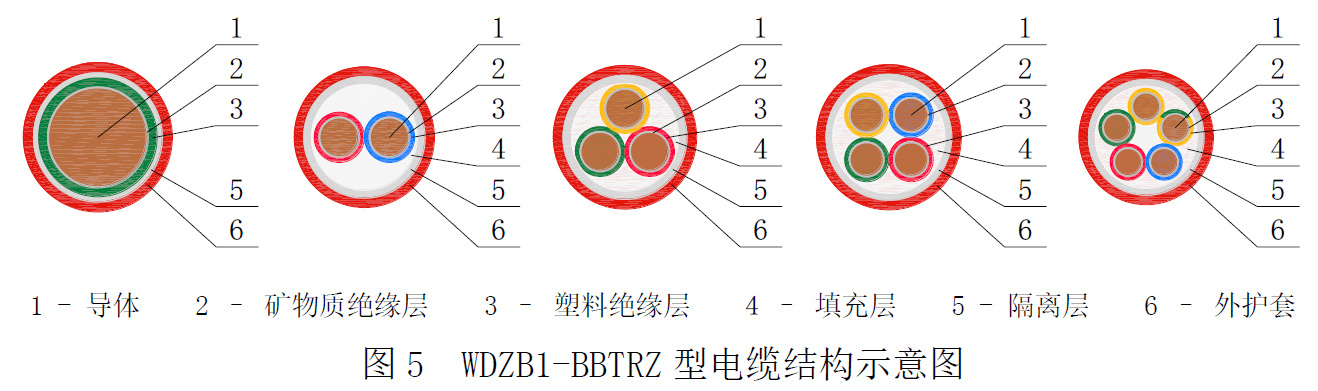

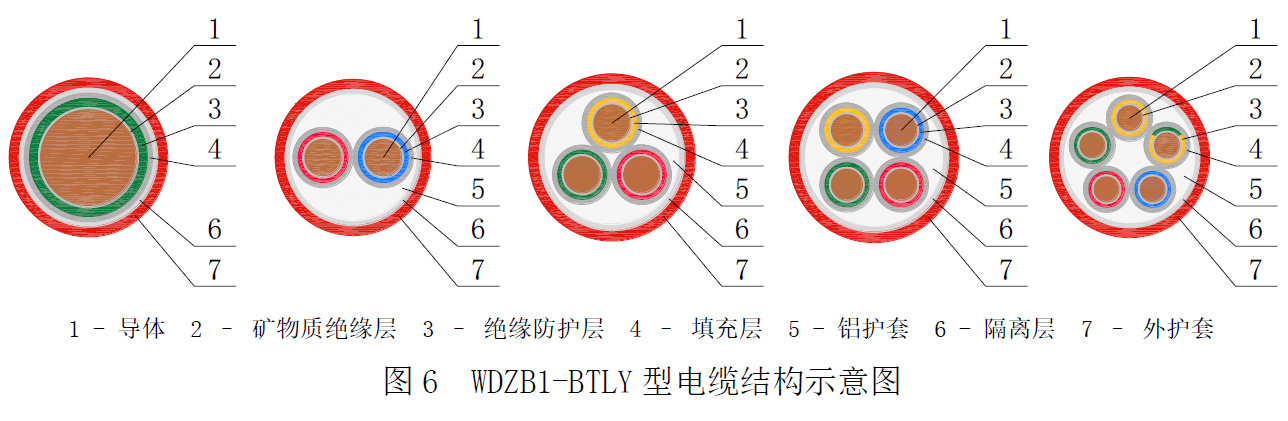

This product is suitable for fire-fighting power distribution lines in densely populated places with rated voltages of 0.6/1kV and below, super high-rise buildings and densely populated places such as airports, subways, hospitals, hotels, large shopping malls, convention and exhibition centers, and finance, telecommunications, radio and television, and power dispatch , Non-fire load lines of important buildings such as data centers. Product performance standards GB 31247-2014 Classification of burning performance of cables and optical cables GB/T 12706.1-2020 Rated voltage 1kV (Um=1.2kV) to 35kV (Um=40.5kV) extruded insulated power cables and accessories Part 1: Rated voltage 1kV (Um=1.2kV) and 3kV (Um=3.6kV) )cable GB/T 19666-2019 Flame-retardant and fire-resistant wire, cable or optical cable general rules product structure WDZB1-YJY cable is composed of conductor, insulation layer, filling layer (except single-core cable), isolation layer and outer sheath from inside to outside, as shown in Figure 1. WDZB1-YJY23 cable is composed of conductor, insulation layer, filling layer, isolation layer, inner lining layer, armor layer and outer sheath from inside to outside, as shown in Figure 2. WDZB1N-YJY cable is composed of conductor, fire-resistant layer, insulating layer, filling layer (except single-core cable), isolation layer and outer sheath from inside to outside, as shown in Figure 3. WDZB1N-YJY23 cable is composed of conductor, refractory layer, insulation layer, filling layer, isolation layer, inner lining layer, armor layer and outer sheath from inside to outside, as shown in Figure 4. WDZB1-BBTRZ cable is composed of conductor, mineral insulation layer, plastic insulation layer, filling layer, isolation layer and outer sheath from inside to outside, as shown in Figure 5. WDZB1-BTLY type cable is composed of conductor, mineral insulation layer, insulation protection layer, aluminum sheath, filling layer, isolation layer and outer sheath from inside to outside, as shown in Figure 6. The aluminum sheath of multi-core cables of 10mm2 and below is a turnkey structure, located between the filling layer and the isolation layer.

Classification:

Key words:

Class B1 flame-retardant and fire-resistant cable

- Description

- Model and specification

- Usage characteristics

- Parameter

- Transportation

-

- Commodity name: Class B1 flame-retardant and fire-resistant cable

- Commodity ID: 1329827712759123968

This product is suitable for fire-fighting power distribution lines in densely populated places with rated voltages of 0.6/1kV and below, super high-rise buildings and densely populated places such as airports, subways, hospitals, hotels, large shopping malls, convention and exhibition centers, and finance, telecommunications, radio and television, and power dispatch , Non-fire load lines of important buildings such as data centers. Product performance standards GB 31247-2014 Classification of burning performance of cables and optical cables GB/T 12706.1-2020 Rated voltage 1kV (Um=1.2kV) to 35kV (Um=40.5kV) extruded insulated power cables and accessories Part 1: Rated voltage 1kV (Um=1.2kV) and 3kV (Um=3.6kV) )cable GB/T 19666-2019 Flame-retardant and fire-resistant wire, cable or optical cable general rules product structure WDZB1-YJY cable is composed of conductor, insulation layer, filling layer (except single-core cable), isolation layer and outer sheath from inside to outside, as shown in Figure 1. WDZB1-YJY23 cable is composed of conductor, insulation layer, filling layer, isolation layer, inner lining layer, armor layer and outer sheath from inside to outside, as shown in Figure 2. WDZB1N-YJY cable is composed of conductor, fire-resistant layer, insulating layer, filling layer (except single-core cable), isolation layer and outer sheath from inside to outside, as shown in Figure 3. WDZB1N-YJY23 cable is composed of conductor, refractory layer, insulation layer, filling layer, isolation layer, inner lining layer, armor layer and outer sheath from inside to outside, as shown in Figure 4. WDZB1-BBTRZ cable is composed of conductor, mineral insulation layer, plastic insulation layer, filling layer, isolation layer and outer sheath from inside to outside, as shown in Figure 5. WDZB1-BTLY type cable is composed of conductor, mineral insulation layer, insulation protection layer, aluminum sheath, filling layer, isolation layer and outer sheath from inside to outside, as shown in Figure 6. The aluminum sheath of multi-core cables of 10mm2 and below is a turnkey structure, located between the filling layer and the isolation layer.

Product introduction

The combustion performance of Class B1 flame retardant and fire-resistant cables is Class B1 specified in GB 31247. It is suitable for fire-fighting power distribution lines in densely populated places with a rated voltage of 0.6/1kV and below, super high-rise buildings, and airports, subways, hospitals, hotels, and large-scale buildings. Non-fire load lines in crowded places such as shopping malls, convention and exhibition centers, and important buildings such as finance, telecommunications, radio and television, power dispatching, and data centers.

Product implementation standards

GB 31247-2014 Cable and optical cable burning performance classification

GB/T 12706.1-2020 Rated voltage 1kV (Um=1.2kV) to 35kV (Um=40.5kV) extruded insulated power cables and accessories Part 1: Rated voltage 1kV (Um=1.2kV) and 3kV (Um= 3.6kV) cable

GB/T 19666-2019 Flame-retardant and fire-resistant wire, cable or optical cable general rulesProduct structure

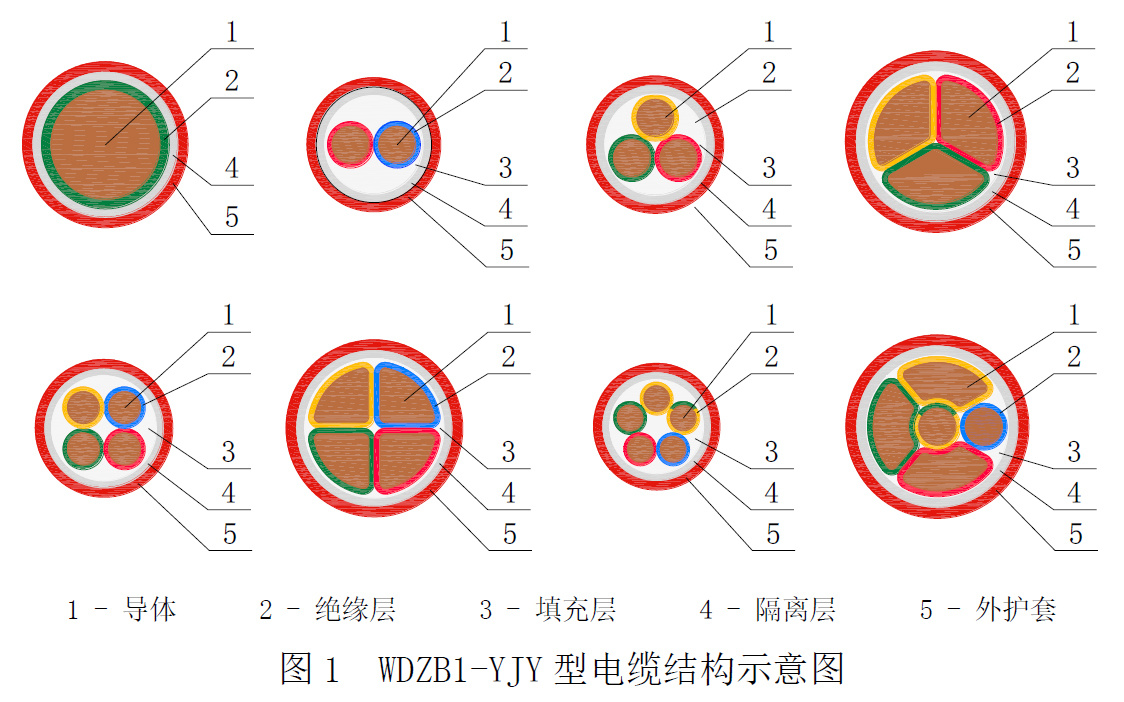

WDZB1-YJY cable is composed of conductor, insulation layer, filling layer (except single-core cable), isolation layer and outer sheath from inside to outside, as shown in Figure 1.

WDZB1-YJY23 cable is composed of conductor, insulating layer, filling layer, isolation layer, inner lining layer, armor layer and outer sheath from inside to outside, as shown in Figure 2.

WDZB1N-YJY cable is composed of conductor, fire-resistant layer, insulation layer, filling layer (except single-core cable), isolation layer and outer sheath from inside to outside, as shown in Figure 3.

WDZB1N-YJY23 cable is composed of conductor, refractory layer, insulation layer, filling layer, isolation layer, inner lining layer, armor layer and outer sheath from inside to outside, as shown in Figure 4.

WDZB1-BBTRZ cable is composed of conductor, mineral insulation layer, plastic insulation layer, filling layer, isolation layer and outer sheath from inside to outside, as shown in Figure 5.

WDZB1-BTLY type cable is composed of conductor, mineral insulation layer, insulation protection layer, aluminum sheath, filling layer, isolation layer and outer sheath from inside to outside, as shown in Figure 6. The aluminum sheath of multi-core cables of 10mm2 and below is a turnkey structure, located between the filling layer and the isolation layer.

-

Model, name and representation

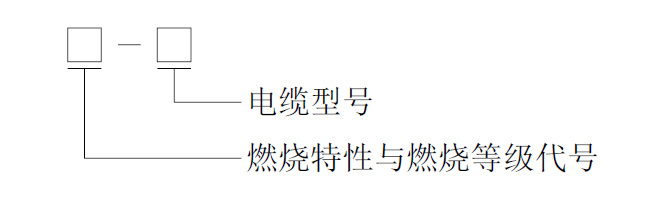

The type of B1 flame-retardant and fire-resistant cable consists of two parts: combustion characteristics, combustion class code, and related cable model.

Code of combustion characteristics:

——Low smoke and halogen free: WD

——Flame retardant: Z

——Fire resistance: N

Burning grade B1 grade code: B1

The model, name and specification range of the product are shown in Table 1.

Table 1 Cable model, name and specification rangeModel

Name

Number of cores

Nominal section/mm2

Rated voltage/kV

WDZB1-YJY

Copper core XLPE insulated halogen-free low-smoke polyolefin sheathed flame-retardant Class B1 power cable

1-5

1-800

0.6/1

WDZB1-YJY23

Copper core XLPE insulated steel tape armored halogen-free low-smoke polyolefin sheathed flame-retardant Class B1 power cable

1-5

1-400

0.6/1

WDZB1N-YJY

Copper core XLPE insulated halogen-free low-smoke polyolefin sheathed flame-retardant Class B1 fire-resistant power cable

1-5

1-800

0.6/1

WDZB1N-YJY23

Copper core XLPE insulated steel tape armored halogen-free low-smoke polyolefin sheathed flame-retardant Class B1 fire-resistant power cable

1-5

1-400

0.6/1

WDZB1-BBTRZ

Copper core mineral composite insulated halogen-free low-smoke polyolefin sheathed flame-retardant Class B1 flexible fireproof cable

1-5

1-800

0.6/1

WDZB1-BTLY

Copper core mineral composite insulated aluminum sheathed halogen-free low-smoke polyolefin outer sheathed flame retardant Class B1 flexible fireproof cable

1-5

1-400

0.6/1

Products are expressed by model, rated voltage, number of cores, nominal cross section, standard number and combustion class.

Example 1: Rated voltage 0.6/1kV copper core XLPE insulated halogen-free low-smoke polyolefin sheathed flame-retardant grade B1 power cable, 3 cores, 240mm2, burning drip/particulate grade d1 grade, smoke Toxicity level t1, corrosion level a1 level

Expressed as: WDZB1-YJY 0.6/1kV 3×240 GB 31247 B1-(d1,t1,a1)/ GB/T 19666-2019/GB/T 12706.1-2020

Example 2: Rated voltage 0.6/1kV copper core XLPE insulated halogen-free low-smoke polyolefin sheathed flame-retardant B1 class fire-resistant power cable, 3-core, 240mm2, burning drip/particulate grade d1, smoke Gas toxicity grade t1, corrosiveness grade a1

Expressed as: WDZB1N-YJY 0.6/1kV 3×240 GB 31247 B1-(d1,t1,a1)/ GB/T 19666-2019/GB/T 12706.1-2020

-

Using features

1 The rated voltage U0/U is 0.6/1kV.

2 The allowable temperature for long-term operation of the cable conductor is 90℃.

3 When short-circuited (the longest duration is 5s), the maximum temperature of the conductor does not exceed 250°C.

4 The minimum ambient temperature during laying and installation is 0℃.

5 Minimum bending radius during laying and installation: see Table 2.

Table 2 Minimum bending radius during cable laying and installation

Project

Single core cable

Multi-core cable

No armor or aluminum sleeve

With armor or aluminum sleeve

No armor or aluminum sleeve

With armor or aluminum sleeve

Minimum bending radius of cable during installation

20D

15D

15D

12D

The minimum bending radius of the cable near the connection box and the terminal (bending should be carefully controlled, such as using a forming guide)

15D

12D

12D

10D

Note: D is the outer diameter of the cable.

Main performance

1 The conductor DC resistance meets the requirements of GB/T 3956.

2 Power frequency withstand voltage test 3500V, duration 5min without breakdown.

3 Combustion performance level

The combustion performance level of the cable reaches B1 level, and the main indicators are:

a. Flame spread FS≤1.5m;

b. Heat release rate peak HRR peak ≤30kW

c. The total heat release within 1200s of exposure to fire is THR1200≤15MJ;

d. Combustion growth rate index FIGRA≤150W/s;

e. Peak smoke production rate peak SPR peak ≤0.25m2/s;

f. The total amount of smoke produced in 1200s after the fire is TSP1200≤50m2;

g. Smoke density (minimum light transmittance) It≥60%;

h. Vertical fire spread H≤425mm.

Additional combustion performance:

a. The grades of burning drips/particulates include three grades: d0, d1 and d2. The classification basis is shown in Table 3;

b. The smoke toxicity grade includes three grades: t0, t1 and t2. The classification basis is shown in Table 4;

c. Corrosion grades include three grades: a1, a2 and a3. See Table 5 for the grading basis.

Table 3 Combustion drips/particulate grades and classification criteria (GB 31247-2014)

Level

Test method

Classification judgment

d0

GB/T 31248-2014

No burning drips/particles in 1200s

d1

The duration of burning drips/particles within 1200s does not exceed 10s

d2

Does not reach level d1

Table 4 Smoke toxicity grade and classification criteria (GB 31247-2014)

Level

Test method

Classification judgment

t0

GB/T 20285

reach ZA2

t1

reach ZA3

t2

Less than level 1

Table 5 Corrosion grade and grading basis (GB 31247-2014)

Level

Test method

Classification judgment

a1

GB/T 17650.2

Conductivity≤2.5μs/mm and pH≥4.3

a2

Conductivity≤10μs/mm and pH≥4.3

a3

Does not reach a2 level

6.4 The amount of halogen acid gas released

The material of the cable is tested according to the test methods specified in GB/T 17650.1 and IEC 60684-2:2011, and the total amount of halogen acid gas released during combustion meets the requirements of GB/T 19666-2019:

——HCl and HBr content≤0.5%;

——HF content≤0.1%.

6.5 In addition to meeting the performance of Class B1 flame-retardant, low-smoke and halogen-free type, Class B1 fire-resistant cables can pass the line integrity test of cables or optical cables under flame conditions specified in GB/T 19216.21, with a flame temperature of 750 (0~ +50) ℃, continue to supply fire for 90 minutes and then cool for 15 minutes. During the test, the 2A fuse will continue and the indicator light will not go out.

-

Using features

1 The rated voltage U0/U is 0.6/1kV.

2 The allowable temperature for long-term operation of the cable conductor is 90℃.

3 When short-circuited (the longest duration is 5s), the maximum temperature of the conductor does not exceed 250°C.

4 The minimum ambient temperature during laying and installation is 0℃.

5 Minimum bending radius during laying and installation: see Table 2.

Table 2 Minimum bending radius during cable laying and installation

Project

Single core cable

Multi-core cable

No armor or aluminum sleeve

With armor or aluminum sleeve

No armor or aluminum sleeve

With armor or aluminum sleeve

Minimum bending radius of cable during installation

20D

15D

15D

12D

The minimum bending radius of the cable near the connection box and the terminal (bending should be carefully controlled, such as using a forming guide)

15D

12D

12D

10D

Note: D is the outer diameter of the cable.

Main performance

1 The conductor DC resistance meets the requirements of GB/T 3956.

2 Power frequency withstand voltage test 3500V, duration 5min without breakdown.

3 Combustion performance level

The combustion performance level of the cable reaches B1 level, and the main indicators are:

a. Flame spread FS≤1.5m;

b. Heat release rate peak HRR peak ≤30kW

c. The total heat release within 1200s of exposure to fire is THR1200≤15MJ;

d. Combustion growth rate index FIGRA≤150W/s;

e. Peak smoke production rate peak SPR peak ≤0.25m2/s;

f. The total amount of smoke produced in 1200s after the fire is TSP1200≤50m2;

g. Smoke density (minimum light transmittance) It≥60%;

h. Vertical fire spread H≤425mm.

Additional combustion performance:

a. The grades of burning drips/particulates include three grades: d0, d1 and d2. The classification basis is shown in Table 3;

b. The smoke toxicity grade includes three grades: t0, t1 and t2. The classification basis is shown in Table 4;

c. Corrosion grades include three grades: a1, a2 and a3. See Table 5 for the grading basis.

Table 3 Combustion drips/particulate grades and classification criteria (GB 31247-2014)

Level

Test method

Classification judgment

d0

GB/T 31248-2014

No burning drips/particles in 1200s

d1

The duration of burning drips/particles within 1200s does not exceed 10s

d2

Does not reach level d1

Table 4 Smoke toxicity grade and classification criteria (GB 31247-2014)

Level

Test method

Classification judgment

t0

GB/T 20285

reach ZA2

t1

reach ZA3

t2

Less than level 1

Table 5 Corrosion grade and grading basis (GB 31247-2014)

Level

Test method

Classification judgment

a1

GB/T 17650.2

Conductivity≤2.5μs/mm and pH≥4.3

a2

Conductivity≤10μs/mm and pH≥4.3

a3

Does not reach a2 level

6.4 The amount of halogen acid gas released

The material of the cable is tested according to the test methods specified in GB/T 17650.1 and IEC 60684-2:2011, and the total amount of halogen acid gas released during combustion meets the requirements of GB/T 19666-2019:

——HCl and HBr content≤0.5%;

——HF content≤0.1%.

6.5 In addition to meeting the performance of Class B1 flame-retardant, low-smoke and halogen-free type, Class B1 fire-resistant cables can pass the line integrity test of cables or optical cables under flame conditions specified in GB/T 19216.21, with a flame temperature of 750 (0~ +50) ℃, continue to supply fire for 90 minutes and then cool for 15 minutes. During the test, the 2A fuse will continue and the indicator light will not go out.

mm

kg/km

mm

kg/km

mm

kg/km

1×10

11.4

250

3×150

41.2

5179

3×16+1×10

22.4

959

1×16

12.2

316

3×185

45.7

6339

3×25+1×16

26.1

1357

1×25

13.8

431

3×240

51.2

8040

3×35+1×16

28.6

1680

1×35

14.8

544

4×1

14.4

267

3×50+1×25

30.2

2189

1×50

16.6

700

4×1.5

14.5

296

3×70+1×35

34.9

2948

1×70

18.5

929

4×2.5

15.4

353

3×95+1×50

38.8

3988

1×95

20.2

1225

4×4

16.6

433

3×120+1×70

42.5

5033

1×120

21.9

1459

4×6

17.8

530

3×150+1×70

46.9

5993

1×150

24

1785

4×10

20.8

775

3×185+1×95

52.6

7424

1×185

26.2

2157

4×16

22.8

1017

3×240+1×120

58.5

9374

1×240

28.9

2718

4×25

26

1455

3×2.5+2×1.5

16.4

377

1×300

31.3

3336

4×35

28.6

1868

3×4+2×2.5

17.7

467

2×1

12.9

209

4×50

28.7

2408

3×6+2×4

19

576

2×1.5

13.3

227

4×70

33.4

3250

3×10+2×6

22.5

807

2×2.5

14.1

262

4×95

37.1

4277

3×16+2×10

24.7

1081

2×4

15.1

317

4×120

40.6

5468

3×25+2×16

29.2

1571

2×6

16.1

374

4×150

45.8

6735

3×35+2×16

32.1

1901

2×10

18.6

506

4×185

51.5

8258

3×50+2×25

29.8

2421

2×16

20.2

640

4×240

56.4

10497

3×70+2×35

34.6

3271

2×25

23.4

911

4×300

62.5

12837

3×95+2×50

38.1

4427

2×35

25.3

1126

5×1

14

298

3×120+2×70

41.3

5627

2×50

23.4

1409

5×1.5

14.7

333

3×150+2×70

46.3

6624

2×70

26.4

1872

5×2.5

15.7

402

3×185+2×95

51.4

8246

2×95

28.3

2422

5×4

17

503

3×240+2×120

57.6

10460

2×120

31.1

3105

5×6

18.4

622

4×2.5+1×1.5

16.2

389

2×150

34.8

3805

5×10

21.8

900

4×4+1×2.5

17.4

485

2×185

37.7

4628

5×16

23.9

1198

4×6+1×4

18.7

599

3×1

13.2

237

5×25

28.4

1757

4×10+1×6

22.1

852

3×1.5

13.7

260

5×35

31.3

2266

4×16+1×10

24.2

1138

3×2.5

14.6

306

5×50

33

2959

4×25+1×16

28.6

1667

3×4

15.6

369

5×70

38.1

4164

4×35+1×16

31.4

2087

3×6

16.7

446

5×95

42.1

5419

4×50+1×25

31.2

2697

3×10

19.4

638

5×120

46.2

6742

4×70+1×35

36.2

3637

3×16

21.2

825

5×150

51.3

8278

4×95+1×50

40.1

4923

3×25

23.7

1184

5×185

57.2

10160

4×120+1×70

43.2

6179

3×35

25.9

1513

5×240

63.4

12963

4×150+1×70

49.5

7478

3×50

27

1877

3×2.5+1×1.5

15.2

340

4×185+1×95

54.3

9216

3×70

30.7

2518

3×4+1×2.5

16.3

414

4×240+1×120

61

11735

3×95

34.2

3266

3×6+1×4

17.5

507

3×120

37.6

4117

3×10+1×6

20.5

728

表7 WDZB1-YJY23交联聚乙烯绝缘钢带铠装无卤低烟聚烯烃护套阻燃B1级电力电缆

规格

理论外径

理论重量

规格

理论外径

理论重量

规格

理论外径

理论重量

mm

kg/km

mm

kg/km

mm

kg/km

2×1

15.9

366

4×10

23.8

1024

3×70+1×35

40

3767

2×1.5

16.3

389

4×16

25.8

1290

3×95+1×50

44.1

5013

2×2.5

17.1

433

4×25

29.2

1786

3×120+1×70

48.2

6150

2×4

18.1

499

4×35

31.8

2262

3×150+1×70

52.7

7204

2×6

19.1

568

4×50

31.9

2804

3×185+1×95

58.8

8822

2×10

21.6

729

4×70

38.6

4081

3×240+1×120

64.5

10906

2×16

23.2

882

4×95

42.3

5187

3×2.5+2×1.5

19.4

570

2×25

26.4

1190

4×120

46.2

6554

3×4+2×2.5

20.7

675

2×35

28.6

1442

4×150

51.5

7900

3×6+2×4

22

799

2×50

26.6

1798

4×185

57.6

9642

3×10+2×6

25.5

1068

2×70

29.6

2681

4×240

62.5

11994

3×16+2×10

27.7

1367

2×95

31.6

3310

4×300

68.7

14488

3×25+2×16

32.8

1921

2×120

34.8

4148

5×1

17

475

3×35+2×16

37.3

2319

2×150

40

4950

5×1.5

17.7

517

3×50+2×25

33.4

3165

2×185

42.9

5862

5×2.5

18.7

599

3×70+2×35

39.7

4099

3×1

16.2

398

5×4

20

715

3×95+2×50

43.4

5388

3×1.5

16.7

427

5×6

21.4

849

3×120+2×70

47

6712

3×2.5

17.6

483

5×10

24.8

1167

3×150+2×70

51.9

7823

3×4

18.6

558

5×16

26.9

1491

3×185+2×95

57.5

9612

3×6

19.7

647

5×25

31.7

2150

3×240+2×120

63.7

11972

3×10

22.4

871

5×35

36.5

3060

4×2.5+1×1.5

19.2

585

3×16

24.2

1078

5×50

38.2

3767

4×4+1×2.5

20.4

695

3×25

26.7

1478

5×70

43.4

5125

4×6+1×4

21.7

824

3×35

29.1

1845

5×95

47.8

6503

4×10+1×6

25.1

1116

3×50

30.2

2213

5×120

51.8

7937

4×16+1×10

27.2

1428

3×70

34.4

2946

5×150

57.4

9642

4×25+1×16

31.9

2022

3×95

39.4

4103

5×185

63.3

11661

4×35+1×16

36.6

2853

3×120

42.8

5024

5×240

69.5

14619

4×50+1×25

36.4

3458

3×150

47

6263

3×2.5+1×1.5

18.2

524

4×70+1×35

41.5

4521

3×185

51.4

7499

3×4+1×2.5

19.3

611

4×95+1×50

45.7

5981

3×240

57.3

9402

3×6+1×4

20.5

718

4×120+1×70

48.8

7312

4×1

17.4

436

3×10+1×6

23.5

974

4×150+1×70

55.1

8715

4×1.5

17.5

471

3×16+1×10

25.4

1226

4×185+1×95

60.4

10654

4×2.5

18.4

540

3×25+1×16

29.3

1682

4×240+1×120

67

13330

4×4

19.6

633

3×35+1×16

31.9

2035

4×6

20.8

744

3×50+1×25

33.8

2596

表8 WDZB1N-YJY交联聚乙烯绝缘无卤低烟聚烯烃护套阻燃B1级耐火电力电缆

规格

理论外径

理论重量

规格

理论外径

理论重量

规格

理论外径

理论重量

mm

kg/km

mm

kg/km

mm

kg/km

1×10

12.2

271

3×150

42.8

5329

3×16+1×10

24

1030

1×16

12.8

337

3×185

47.3

6479

3×25+1×16

27.9

1450

1×25

14.5

456

3×240

52.8

8220

3×35+1×16

30.4

1766

1×35

15.6

570

4×1

16.1

316

3×50+1×25

32

2308

1×50

17.6

730

4×1.5

16.2

347

3×70+1×35

36.6

3061

1×70

19.2

962

4×2.5

17.1

407

3×95+1×50

40.5

4136

1×95

20.9

1262

4×4

18.3

489

3×120+1×70

44.7

5179

1×120

22.7

1498

4×6

19.5

590

3×150+1×70

48.6

6170

1×150

24.8

1840

4×10

22.6

843

3×185+1×95

54.4

7592

1×185

26.9

2205

4×16

24.5

1091

3×240+1×120

60.2

9587

1×240

29.6

2772

4×25

27.8

1552

3×2.5+2×1.5

18.3

436

1×300

31.3

3394

4×35

30.4

1973

3×4+2×2.5

19.6

530

2×1

14.3

244

4×50

30.3

2531

3×6+2×4

20.9

644

2×1.5

14.7

263

4×70

35

3384

3×10+2×6

24.5

882

2×2.5

15.5

300

4×95

38.8

4546

3×16+2×10

26.6

1165

2×4

16.5

356

4×120

42.3

5641

3×25+2×16

31.2

1665

2×6

17.5

414

4×150

47.5

6898

3×35+2×16

34.6

2001

2×10

20.1

550

4×185

53.1

8460

3×50+2×25

31.8

2558

2×16

21.6

686

4×240

58

10693

3×70+2×35

36.6

3403

2×25

24.8

963

4×300

64.2

13050

3×95+2×50

40.1

4599

2×35

26.8

1181

5×1

15.9

355

3×120+2×70

43.3

5820

2×50

25

1470

5×1.5

16.5

392

3×150+2×70

48.4

6805

2×70

27.9

1956

5×2.5

17.6

465

3×185+2×95

53.6

8469

2×95

29.8

2514

5×4

18.9

569

3×240+2×120

59.8

10706

2×120

33

3201

5×6

20.2

692

4×2.5+1×1.5

18

450

2×150

36.5

3933

5×10

23.8

978

4×4+1×2.5

19.3

550

2×185

39.2

4735

5×16

25.8

1283

4×6+1×4

20.6

668

3×1

14.8

279

5×25

30.4

1871

4×10+1×6

24.1

930

3×1.5

15.3

303

5×35

33.7

2390

4×16+1×10

26.1

1224

3×2.5

16.1

351

5×50

35.4

3117

4×25+1×16

30.6

1764

3×4

17.1

416

5×70

40.4

4347

4×35+1×16

33.9

2191

3×6

18.2

495

5×95

44.8

5597

4×50+1×25

33.7

2828

3×10

21

693

5×120

49.1

6946

4×70+1×35

38.5

3922

3×16

22.7

885

5×150

53.7

8525

4×95+1×50

42.3

5106

3×25

25.2

1251

5×185

59.7

10436

4×120+1×70

72.7

6384

3×35

27.5

1598

5×240

65.7

13274

4×150+1×70

51.6

7672

3×50

28.6

1978

3×2.5+1×1.5

16.9

392

4×185+1×95

56.4

9454

3×70

32.7

2627

3×4+1×2.5

18

469

4×240+1×120

63

11998

3×95

35.8

3384

3×6+1×4

19.2

565

3×120

39.2

4374

3×10+1×6

22.3

793

表9 WDZB1N-YJY23交联聚乙烯绝缘钢带铠装无卤低烟聚烯烃护套阻燃B1级耐火电力电缆

规格

理论外径

理论重量

规格

理论外径

理论重量

规格

理论外径

理论重量

mm

kg/km

mm

kg/km

mm

kg/km

2×1

10.06

417

4×10

18.30126

1112

3×70+1×35

32.32

3953

2×1.5

10.52

442

4×16

20.2566

1386

3×95+1×50

36.416

5204

2×2.5

11.32

487

4×25

24.519

1905

3×120+1×70

40.081

6336

2×4

12.26

555

4×35

27.133

2391

3×150+1×70

43.977

7398

2×6

13.26

625

4×50

27.08

2949

3×185+1×95

49.228

9031

2×10

15.78

789

4×70

31.44

4255

3×240+1×120

54.71

11164

2×16

17.4

945

4×95

35.16

5566

3×2.5+2×1.5

13.636

651

2×25

20.8

1272

4×120

38.86

6768

3×4+2×2.5

14.858

759

2×35

22.8

1514

4×150

43.02

8126

3×6+2×4

16.158

888

2×50

26.2

1877

4×185

48.7

9886

3×10+2×6

19.434

1164

2×70

30.2

2784

4×240

53.08

12230

3×16+2×10

21.74

1485

2×95

33.6

3419

4×300

59.2

14741

3×25+2×16

26.1

2071

2×120

37.2

4289

5×1

12.321

554

3×35+2×16

29.1

2818

2×150

41.6

5126

5×1.5

12.942

598

3×50+2×25

28.064

3350

2×185

45.8

6089

5×2.5

14.022

684

3×70+2×35

32.344

4296

3×1

10.55742

457

5×4

15.291

803

3×95+2×50

36.008

5657

3×1.5

11.05284

488

5×6

16.641

942

3×120+2×70

39.2

6956

3×2.5

11.91444

546

5×10

20.043

1268

3×150+2×70

43.752

8051

3×4

12.92682

622

5×16

22.43

1612

3×185+2×95

48.368

9886

3×6

14.00382

714

5×25

27.15

2290

3×240+2×120

54.208

12269

3×10

16.71786

944

5×35

30.05

3214

4×2.5+1×1.5

13.829

667

3×16

18.4626

1156

5×50

31.105

3980

4×4+1×2.5

15.0745

781

3×25

22.109

1576

5×70

36.31

5412

4×6+1×4

16.3995

915

3×35

24.463

1951

5×95

40.23

6758

4×10+1×6

19.7385

1216

3×50

24.678

2333

5×120

43.84

8195

4×16+1×10

22.085

1548

3×70

28.454

3428

5×150

48.58

9948

4×25+1×16

26.725

2192

3×95

31.608

4259

5×185

54.095

11997

4×35+1×16

29.575

3020

3×120

34.973

5389

5×240

60.23

14989

4×50+1×25

29.42

3652

3×150

38.749

6453

3×2.5+1×1.5

12.671

595

4×70+1×35

34.129

4935

3×185

42.747

7700

3×4+1×2.5

13.7755

685

4×95+1×50

37.943

6191

3×240

47.789

9623

3×6+1×4

14.9505

795

4×120+1×70

41.062

7544

4×1

11.39722

504

3×10+1×6

17.9115

1058

4×150+1×70

46.466

9043

4×1.5

11.95244

542

3×16+1×10

19.815

1317

4×185+1×95

51.314

10945

4×2.5

12.91804

613

3×25+1×16

23.975

1797

4×240+1×120

57.552

13646

4×4

14.05262

709

3×35+1×16

26.525

2191

4×6

15.25962

824

3×50+1×25

28.193

3103

表10 WDZB1-BBTRZ矿物复合绝缘无卤低烟聚烯烃护套阻燃B1级柔性防火电缆

规格

理论外径

理论重量

规格

理论外径

理论重量

规格

理论外径

理论重量

mm

kg/km

mm

kg/km

mm

kg/km

1×10

11.5

203

3×120

44.1

4454

3×6+1×4

19.1

561

1×16

12.3

263

3×150

48.6

5519

3×10+1×6

22.2

795

1×25

13.9

370

3×185

53.3

6649

3×16+1×10

24.1

1055

1×35

14.9

470

3×240

59.5

8357

3×25+1×16

27.8

1440

1×50

16.7

618

3×300

64.8

10234

3×35+1×16

30.4

1803

1×70

18.5

827

4×1

15.5

311

3×50+1×25

34.6

2430

1×95

20.3

1080

4×1.5

16.1

342

3×70+1×35

39.4

3250

1×120

22.1

1329

4×2.5

17.1

402

3×95+1×50

43.5

4214

1×150

24.1

1641

4×4

18.2

485

3×120+1×70

47.5

5287

1×185

26.3

1988

4×6

19.4

587

3×150+1×70

52.6

6349

1×240

29.0

2518

4×10

22.6

846

3×185+1×95

57.9

7781

1×300

31.5

3105

4×16

24.6

1094

3×240+1×120

64.2

9768

2×1

14.1

237

4×25

28.6

1554

3×2.5+2×1.5

17.8

433

2×1.5

14.6

256

4×35

31.2

1975

3×4+2×2.5

19.1

528

2×2.5

15.4

292

4×50

35.3

2663

3×6+2×4

20.4

641

2×4

16.3

349

4×70

40.4

3609

3×10+2×6

23.8

886

2×6

17.3

408

4×95

44.5

4663

3×16+2×10

25.9

1216

2×10

19.9

548

4×120

48.6

5780

3×25+2×16

30.3

1670

2×16

21.6

702

4×150

53.8

7115

3×35+2×16

33.1

2007

2×25

24.8

961

4×185

59.4

8627

3×50+2×25

38.0

2782

2×35

26.8

1180

4×240

66.9

10953

3×70+2×35

42.9

3674

2×50

30.2

1550

4×300

72.8

13454

3×95+2×50

47.5

4798

2×70

34.0

2051

5×1

16.6

352

3×120+2×70

52.2

6068

2×95

38.0

2659

5×1.5

17.2

389

3×150+2×70

57.8

7204

2×120

41.4

3212

5×2.5

18.3

462

3×185+2×95

64.4

8901

2×150

45.6

3910

5×4

19.5

567

3×240+2×120

71.5

11229

2×185

50.0

4750

5×6

20.9

690

4×2.5+1×1.5

18.0

448

2×240

55.2

5908

5×10

24.4

985

4×4+1×2.5

19.3

547

3×1

14.6

272

5×16

26.6

1290

4×6+1×4

20.6

666

3×1.5

15.1

296

5×25

31.3

1890

4×10+1×6

24.1

935

3×2.5

16.0

345

5×35

34.2

2410

4×16+1×10

26.3

1253

3×4

17.0

410

5×50

39.2

3245

4×25+1×16

30.7

1770

3×6

18.1

489

5×70

44.4

4367

4×35+1×16

33.6

2197

3×10

20.9

693

5×95

48.9

5688

4×50+1×25

38.6

3015

3×16

22.7

885

5×120

53.7

7059

4×70+1×35

43.8

4030

3×25

26.1

1252

5×150

59.9

8798

4×95+1×50

48.2

5243

3×35

28.5

1598

5×185

66.7

10685

4×120+1×70

53.2

6580

3×50

32.1

2128

5×240

74.0

13574

4×150+1×70

58.9

8014

3×70

36.2

2799

3×2.5+1×1.5

16.8

387

4×185+1×95

65.6

9808

3×95

40.4

3661

3×4+1×2.5

17.9

464

4×240+1×120

72.7

12385

表11 WDZB1-BTLY矿物复合绝缘铝护套无卤低烟聚烯烃外护套阻燃B1级柔性防火电缆

规格

理论外径

理论重量

规格

理论外径

理论重量

规格

理论外径

理论重量

mm

kg/km

mm

kg/km

mm

kg/km

1×10

16.0

357

3×120

49.2

4751

3×6+1×4

22.6

672

1×16

17.0

429

3×150

53.4

5831

3×10+1×6

25.6

912

1×25

19.2

568

3×185

57.6

6952

3×16+1×10

27.8

1231

1×35

20.2

677

3×240

64.2

8724

3×25+1×16

32.0

1652

1×50

21.4

840

3×300

69.4

10597

3×35+1×16

34.2

2020

1×70

23.4

1071

4×1

18.6

404

3×50+1×25

38.4

2660

1×95

25.6

1360

4×1.5

19.6

445

3×70+1×35

43.8

3527

1×120

26.6

1613

4×2.5

20.6

509

3×95+1×50

48.0

4499

1×150

28.8

1961

4×4

21.6

592

3×120+1×70

52.4

5624

1×185

31.0

2344

4×6

22.6

692

3×150+1×70

57.6

6692

1×240

34.2

2929

4×10

25.6

987

3×185+1×95

62.0

8152

1×300

36.2

3536

4×16

27.8

1257

3×240+1×120

68.4

10176

2×1

17.6

335

4×25

32.0

1741

3×2.5+2×1.5

21.6

546

2×1.5

18.6

366

4×35

35.2

2188

3×4+2×2.5

22.6

639

2×2.5

18.6

389

4×50

38.4

2879

3×6+2×4

23.6

751

2×4

19.6

450

4×70

44.8

3874

3×10+2×6

26.6

995

2×6

20.6

511

4×95

49.2

4977

3×16+2×10

29.8

1412

2×10

23.6

668

4×120

53.4

6119

3×25+2×16

34.2

1902

2×16

24.6

814

4×150

58.8

7514

3×35+2×16

36.2

2221

2×25

28.8

1111

4×185

64.2

9093

3×50+2×25

41.6

3030

2×35

31.0

1351

4×240

70.6

11398

3×70+2×35

47.0

3974

2×50

34.2

1731

4×300

75.8

13850

3×95+2×50

52.4

5149

2×70

37.4

2235

5×1

19.6

448

3×120+2×70

56.6

6434

2×95

42.8

2887

5×1.5

20.6

493

3×150+2×70

62.0

7591

2×120

46.0

3436

5×2.5

21.6

568

3×185+2×95

67.4

9293

2×150

50.2

4151

5×4

22.6

671

3×240+2×120

74.8

11639

2×185

54.4

4999

5×6

24.6

810

4×2.5+1×1.5

21.6

557

2×240

59.8

6204

5×10

27.8

1158

4×4+1×2.5

22.6

655

3×1

18.6

381

5×16

29.8

1471

4×6+1×4

23.6

771

3×1.5

18.6

397

5×25

35.2

2113

4×10+1×6

27.8

1071

3×2.5

19.6

450

5×35

37.4

2635

4×16+1×10

29.8

1446

3×4

20.6

518

5×50

43.8

3540

4×25+1×16

34.2

1998

3×6

21.6

598

5×70

49.2

4699

4×35+1×16

37.4

2448

3×10

24.6

831

5×95

53.4

6041

4×50+1×25

42.8

3301

3×16

25.6

1014

5×120

57.6

7407

4×70+1×35

48.0

4330

3×25

29.8

1418

5×150

64.2

9215

4×95+1×50

52.4

5588

3×35

32.0

1773

5×185

69.4

11070

4×120+1×70

57.6

6937

3×50

36.2

2330

5×240

77.0

14008

4×150+1×70

63.0

8392

3×70

39.6

3020

3×2.5+1×1.5

20.6

498

4×185+1×95

68.4

10186

3×95

44.8

3905

3×4+1×2.5

21.6

576

4×240+1×120

75.8

12810

-

Delivery length

1 The delivery length of the cable is generally not less than 100m, and it is allowed to deliver according to the length stipulated in the contract between the two parties.

2 The deviation of the delivery length shall be implemented in accordance with the relevant laws, regulations, standards or contractual provisions in effect.

Packaging logo and transportation

1 The cable can be packaged in coils or coils. When using reel packaging, the cable should be properly packaged on the cable delivery reel, the length of the cable head should not be less than 300mm, and the end should be reliably sealed with a cable jacket.

2 When packaging in a reel, each cable package should be accompanied by a product quality certificate. The certificate should be placed in an impermeable bag and fixed on the side of the cable reel, indicating:

a. The name or trademark of the manufacturer;

b. Cable model and specifications;

c. Length: m;

d. Date of manufacture: year month;

e. Standard number;

f. Gross weight: kg;

g. Indicates the compliance of the correct rotation direction of the cable reel.

Product transportation and storage

a. The cable should be stored in the open air, and the cable reel is not allowed to be transported or stored flat.

b. The transportation and storage of cables should avoid strong vibration, dumping, moisture, and corrosion. During transportation, loading and unloading, avoid damage to cables and cable reels.

c. Product loading and unloading should be carried out by crane, steam crane or other suitable loading and unloading equipment and tools. During loading and unloading, a steel shaft is inserted into the center hole of the cable reel, and steel ropes are placed on both ends of the shaft for lifting. It is strictly forbidden to directly push down from the transport vehicle or throw down the cable reel with cables from a height.

d. When hoisting packages, it is strictly forbidden to hoist several reels at the same time. On vehicles, ships and other transported parts, the cable reels should be placed stably and fixed with appropriate methods to prevent mutual collision or overturning.

e. Before transporting or rolling the cable reel, make sure that the cable reel is firm and the cable should be wound tightly. When rolling, you must follow the arrow indication on the cable reel or the tight direction of the cable.

f. Cables should be stored in a centralized and categorized manner, and the rated voltage, model specifications, and length should be marked; there should be passages between the cable reels; the foundation should be solid, and when the conditions are limited, the under-the-reel should be padded; the storage place should be kept Ventilated, dry and free from accumulation of water.

g. During the storage of the cable, the cable reel and packaging should be intact, the markings should be complete, and the ends should be tightly sealed. When there is a defect, it should be dealt with in time.

Previous

Next

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!