Fluid liquid explosion-proof electric heater

Liquid explosion-proof electric heater (hereinafter referred to as electric heater) is a heating device specially designed to increase the temperature of the flowing medium in the pipeline. The mineral insulated (MI) heating cable is selected as the heating element. The structure is firm, durable, reliable, and has a long service life. It can ensure that the heated medium does not coke. It is suitable for the heating of various flowing media, especially suitable for heating the media with high viscosity, viscosity or high temperature quality requirements (such as crude oil, asphalt, residual oil, heavy diesel oil, animal and vegetable oils, etc.). It is widely used in petroleum, chemical, pharmaceutical, metallurgy, glass, power generation and other industrial sectors. Typical applications include offshore oil platforms, wellhead heating in oil fields, high-temperature atomization before combustion in oil-fired kilns, centralized air-conditioning hot water boilers, etc. .

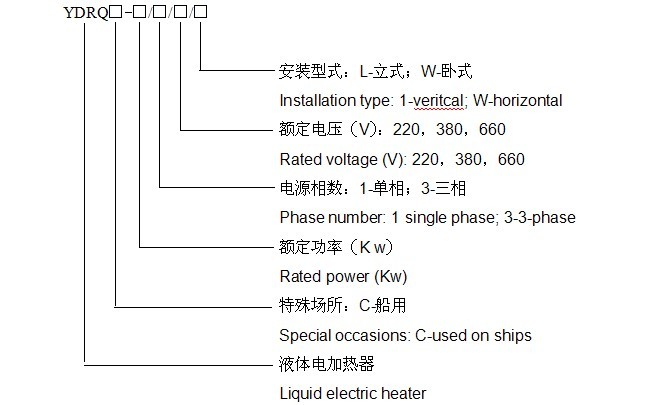

Classification:

Key words:

Fluid liquid explosion-proof electric heater

- Description

- Specification

- parameter

- output power

- Application

-

- Commodity name: Fluid liquid explosion-proof electric heater

- Commodity ID: 1329827716127150080

Liquid explosion-proof electric heater (hereinafter referred to as electric heater) is a heating device specially designed to increase the temperature of the flowing medium in the pipeline. The mineral insulated (MI) heating cable is selected as the heating element. The structure is firm, durable, reliable, and has a long service life. It can ensure that the heated medium does not coke. It is suitable for the heating of various flowing media, especially suitable for heating the media with high viscosity, viscosity or high temperature quality requirements (such as crude oil, asphalt, residual oil, heavy diesel oil, animal and vegetable oils, etc.). It is widely used in petroleum, chemical, pharmaceutical, metallurgy, glass, power generation and other industrial sectors. Typical applications include offshore oil platforms, wellhead heating in oil fields, high-temperature atomization before combustion in oil-fired kilns, centralized air-conditioning hot water boilers, etc. .

Liquid explosion-proof electric heater (hereinafter referred to as electric heater) is a heating device specially designed to increase the temperature of the flowing medium in the pipeline. The mineral insulated (MI) heating cable is selected as the heating element. The structure is firm, durable, reliable, and has a long service life. It can ensure that the heated medium does not coke. It is suitable for the heating of various flowing media, especially suitable for heating the media with high viscosity, viscosity or high temperature quality requirements (such as crude oil, asphalt, residual oil, heavy diesel oil, animal and vegetable oils, etc.). It is widely used in petroleum, chemical, pharmaceutical, metallurgy, glass, power generation and other industrial sectors. Typical applications include offshore oil platforms, wellhead heating in oil fields, high-temperature atomization before combustion in oil-fired kilns, centralized air-conditioning hot water boilers, etc. .

-

Technical data

Table 1 Technical data and dimensions of vertical electric heaters

Model

Rated power

Kw

Rated voltage

(V)

Rated current (A)

Outline dimension (mm)

Body weight (Kg)

H

h1

D

φ1

φ2

φ3

6.3

MPa

4.0

MPa

2.5

MPa

YDRQ-15/3/380/L

15

380

22.8

1974

400

273

400

360

4-Φ22

340

250

200

YDRQ-30/3/380/L

30

380

45.6

1884

544

377

560

480

4-Φ26

660

500

435

YDRQ-50/3/380/L

50

380

76

2350

544

377

560

480

4-Φ30

840

610

530

YDRQ-80/3/380/L

80

380

122

1480

600

500

720

620

4-Φ34

1480

1270

1030

YDRQ-100/3/380/L

100

380

152

1850

600

500

720

620

4-Φ34

1640

1360

1110

YDRQ-150/3/380/L

150

380

228

3220

648

600

850

750

4-Φ34

2130

1720

1460

YDRQ-200/3/380/L

200

380

304

3500

648

600

850

750

4-Φ36

2490

1940

1700

YDRQ-250/3/380/L

250

380

380

3782

822

1000

1300

1200

4-Φ40

7200

5430

4480

YDRQ-300/3/380/L

300

380

456

4818

822

1000

1300

1200

4-Φ42

7600

5950

4940

YDRQ-600/3/380/L

600

380

912

5154

910

1200

1600

1450

4-Φ44

12500

9880

8280

Note: The inlet and outlet diameter of the external process connection is the same. The conventional production specification of the pipe diameter is φ25~φ100, which is selected by the user, and the factory is responsible for configuring the pair of welding flanges.

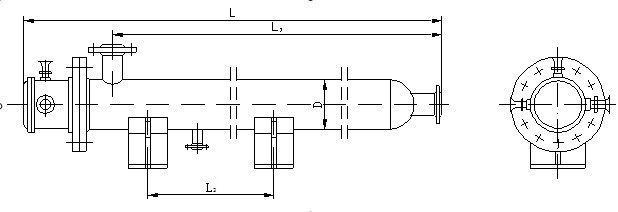

Table 2 Technical data and dimensions of horizontal electric heaters

Model

Rated power Kw

Rated voltage (V)

Rated current (A)

Number of power phases

Outline dimension (mm)

Body weight (Kg)

L

L1

L2

D

6.3

MPa

4.0

MPa

2.5

MPa

YDRQ-3/1/220/W

3

220

13.5

1

1100

750

450

φ159

85

55

45

YDRQ-5/1/220/W

5

220

22.5

1

1300

1000

750

φ159

100

60

50

YDRQ-7.5/1/220/W

7.5

220

34

1

1650

1300

1000

φ159

110

65

52

YDRQ-10/3/380/W

10

380

15

3

1460

1050

750

φ219

180

160

130

YDRQ-15/3/380/W

15

380

22.8

3

1974

1400

1200

φ273

350

260

210

YDRQ-20/3/380/W

20

380

30

3

2200

1620

1300

φ273

380

292

243

YDRQ-30/3/380/W

30

380

45.6

3

2210

1850

1340

φ377

660

510

460

YDRQ-50/3/380/W

50

380

76

3

2750

2200

1600

φ377

840

615

540

YDRQ-80/3/380/W

80

380

122

3

1550

1210

750

φ530

1435

1260

1090

YDRQ-100/3/380/W

100

380

152

3

1950

1400

1200

φ530

1600

1360

1158

YDRQ-150/3/380/W

150

380

228

3

3520

3000

2300

φ630

2185

1850

1460

YDRQ-200/3/380/W

200

380

304

3

3750

3500

2450

φ630

2350

1900

1720

YDRQ-250/3/380/W

250

380

380

3

3780

3500

2450

φ1000

7200

5450

4450

YDRQ-300/3/380/W

300

380

456

3

4100

3600

2800

φ1000

1950

5900

4900

YDRQ-600/3/380/W

600

380

912

3

5100

4000

3200

φ1200

12500

9800

8200

Note: The inlet and outlet diameter of the external process connection is the same. The conventional production specification of the pipe diameter is φ25~φ100, which is selected by the user, and the factory is responsible for configuring the butt welding flange.

-

Technical parameters:

-

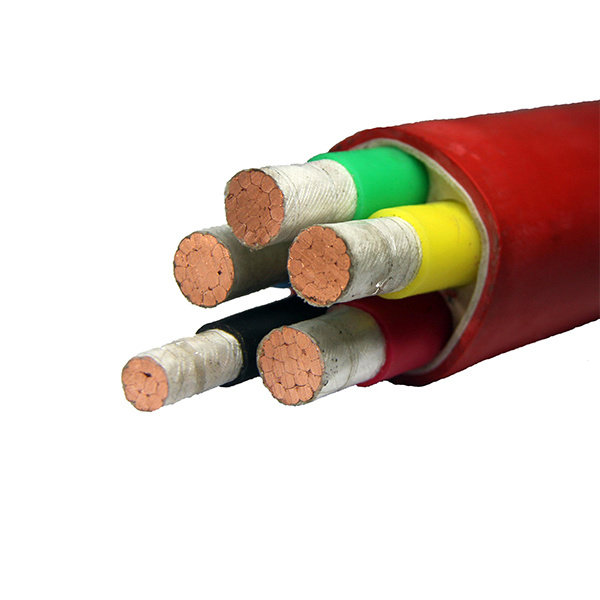

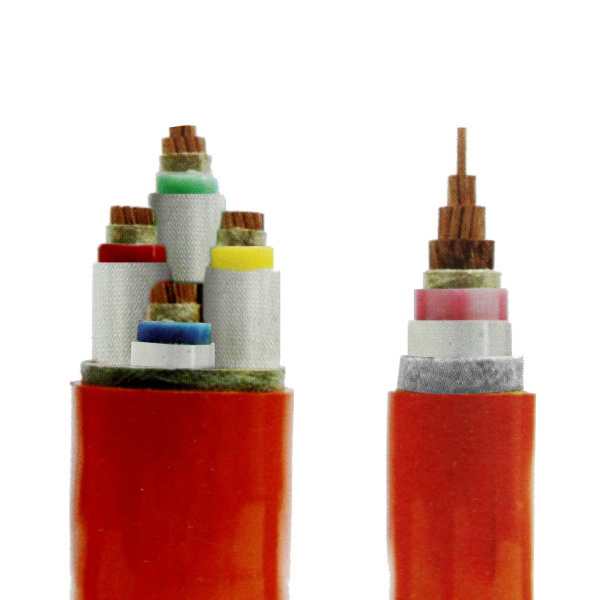

Technical performance and characteristics

1. The heating element of this product is a (MI) heating cable, with good thermal conductivity, and the temperature difference between the heating core and the surface metal sheath is very small. At the same time, according to the process requirements, the surface heat load density of the heating element of the MI heating cable can be accurately designed. Under the premise of ensuring the total heating power, the heated medium will not be coked. It solves the long-standing shortcomings of carbon deposits, tube bursts, broken cores, and short life spans of traditional tubular electric heaters. Heating elements can be divided into copper, copper alloy sheaths and stainless steel sheaths according to the user's use temperature and location.

2. The shell of the electric heater is welded by seamless steel pipes and flanges. The overall structure is tight and strong, with good pressure-bearing and sealing performance, safe to use, and working pressure from 2.5MPa to 6.4MPa.

3. The device connection and electrical connection meet the explosion-proof requirements, and the explosion-proof grade is d IIBT1—T6.

4. Two sets of temperature sensors are installed in the electric heater to detect the temperature of the medium and the surface temperature of the heating element. At the same time, the flow opening and closing lock device can be selected according to the user's needs. When the medium does not flow, the electric heater will automatically stop heating.

5. No need for daily maintenance, easy installation and convenient maintenance.

6. The product has strong practicability and adaptability, and various non-standard types of electric heaters can be designed according to different uses and special requirements put forward by users.

Note: When designing and applying electric heaters outdoors, the explosion-proof junction box should have a rainproof shed to prevent rainwater from penetrating the cracks of the explosion-proof surface through the wet insulation material.

Working principle

The cold medium enters the shunt chamber through the oil inlet, so that the medium flows into the mixing chamber along the circumference of the heating element, and the mixed medium flows out of the oil outlet at a uniform temperature. The mixed flow chamber is equipped with a temperature measuring sensor, which collects temperature signals and transmits them to the electric control system. The primary circuit is controlled by the temperature adjustment instrument to realize automatic temperature control of the oil product temperature. After the electric heater is overheated by the oil or the electric heating element, the protection device will automatically cut off the power supply, and the control cabinet will send out an audible and visual alarm signal at the same time (see the company's WK series electric heating control cabinet instruction manual for details).

-

1. Installation

1.1 The heater support or base should be fixed on a stable and firm foundation. The horizontal electric heater is installed horizontally. The oil outlet is vertically upward, and a straight pipe section is required before the oil inlet and after the oil outlet, and a bypass pipeline is installed in the process design to meet the needs of electric heater maintenance and seasonal flexible operation. A space equal to the length of the heater should be reserved on the front side of the heater junction box for core-pulling overhaul.

1.2 Before installing the electric heater, use a 1000V shaking meter to check the insulation resistance between the main terminal and the shell, insulation resistance ≥1.5MΩ, marine electric heater insulation resistance ≥10MΩ; and check the body and various components Whether there are obvious defects.

1.3 The temperature control cabinet produced by our factory is generally non-explosion-proof equipment and should be installed outside the explosion-proof area (safe area). Carry out a comprehensive inspection during installation, and connect correctly according to the wiring diagram provided by the factory.

1.4 The selection of cables is carried out in accordance with relevant specifications. The cables must be copper core wires and connected with lugs. Electrical connections in explosion-proof places must meet explosion-proof requirements.

1.5 The electric heater is equipped with a dedicated grounding bolt, and the user reliably connects the grounding wire to the bolt. The grounding wire is a multi-strand copper wire of 4mm2 or more, and the grounding resistance is ≤10Ω.

1.6 After the wiring is completed, the joints of the explosion-proof junction box must be coated with industrial petroleum jelly to ensure that the seal is intact.

2. Trial run

2.1 Check the insulation of the system again before trial operation; check whether the power supply voltage is consistent with the nameplate; recheck whether the electrical connection is correct.

2.2 Set various process temperature constants according to the provisions of the temperature regulator instruction manual.

2.3 The over-temperature protector of the heater has been set according to the explosion-proof temperature, and only needs to be confirmed on site.

2.4 Before the electric heater replaces the air, first open the inlet and outlet pipeline valves, close the bypass valve, and replace it normally for a period of time. After ensuring that the medium is full, the electric heater can manually enter the normal trial operation. (The replacement of special medium needs to be discussed separately)

2.5 If the manual operation is normal, you can switch to the automatic operation state, operate correctly and record the voltage, current, temperature and other relevant data during operation. After the trial operation is 2 hours without abnormal conditions, the equipment can be handed over.

2.6 After the test run is successful, please keep the electric heater well insulated in time.

Previous

WRITE A MESSAGE TO US

If you are interested in our products, please leave your email, we will contact you as soon as possible, thank you!